2 2 4 R R

Operating instructions and warnings

20

In case the gate structural features do not allow you to comply with the above force limits, it is possible

to use external safety devices inputs (terminals no. 11 and no. 12). “SIC1” and “SIC2” inputs can be

configured by setting properly parameter no. 18:

•P018 = 0 “rib” mode functioning: SIC1 = motor 1 rib input, SIC2 = motor 2 rib input. When one of the

two inputs is activated the movement direction of both motors is inverted. If one of the two inputs is acti-

vated during the slow-down phase, the activation is interpreted as stroke end thus stopping the movement

of the motor associated to that input.

•P018 = 1 “photoelectric barriers” mode functioning: you can use either “SIC1” or “SIC2” or both of

them, but remember to short-circuit the unused input. When one of the two inputs is activated, the move-

ment of both motors is stopped.

If you power external safety devices t 24VSIC output (terminal no.14), their proper working is

tested before each manoeuvre.

8.7

Messages shown on the display

224RR control board allows you to visualize on the display several messages concerning its working

status and any malfunction:

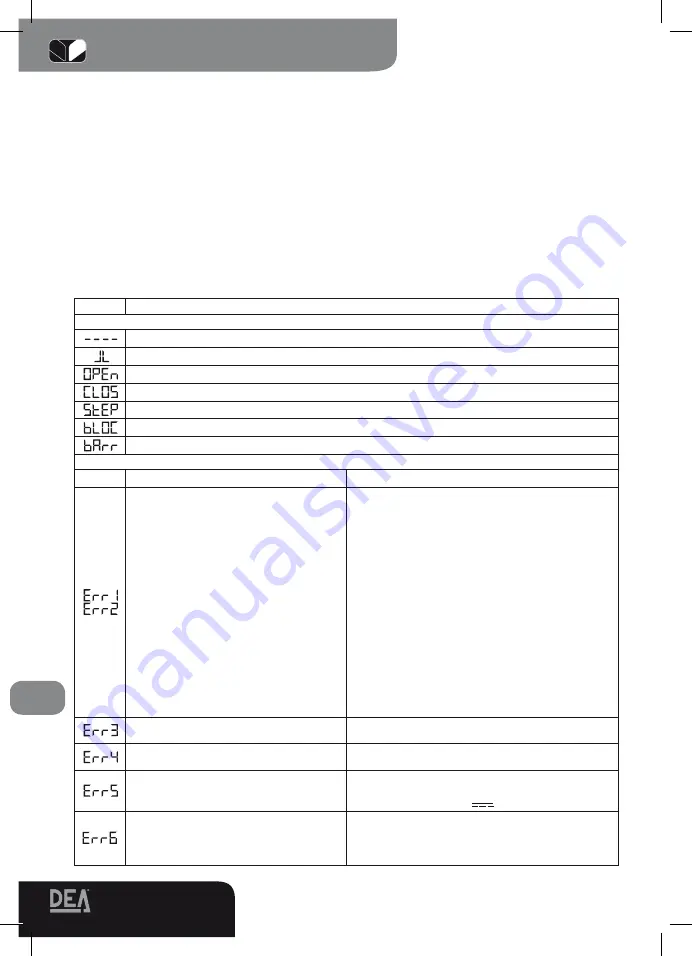

Message

Description

MESSAGES CONCERNING WORKING STATUS

Gate is closed

Gate is open

Opening under way

Closing under way

While in step-by-step mode, the control board awaits further instructions after a start command

Stop command received

Sic1 or sic2 activated while working in barrier mode

ERROR MESSAGES

Message

Description

Possible solutions

They point out that the gate has excee-

ded:

-(Err1), the max allowed number of

reversals (50) without ever reaching the

end of stroke (or stop) while closing;

-(Err2) the max number of uninterrupted

operations (10) of the anti-crush safety

device;therefore an “emergency maneu-

ver” is under way: the control board sets

the motors in a slow down phase and

searches the stops (or ends of stroke)

in order to reset the positioning system.

Once the stops (or ends of stroke) while

closing are found again the message

disappears and the control board awaits

further instructions “----” and then resu-

mes working normally.

In case the gate is not properly closed after the

emergency maneuver (maybe because of false

stops or obstacles due to mechanical frictions),

proceed as follows:

- Disconnect the power supply, check manually

that no particular frictions and/or obstacles are

present during the complete stroke of both leafs.

Leave both leafs half-open.

- Connect the power supply again and subsequen-

tly give a start pulse. At this point both leafs will

start to close in slow down phase until reaching the

stop (or end of stroke). Make sure that the maneu-

ver is properly completed. Adjust force and motor

speed values, if need be.

If the gate keeps working inappropriately try to

repeat the motor stroke memorization procedure

(see paragraph 8.2)

External photocells and/or safety devices

are activated or out of order

Make sure that all safety devices and/or photocells

installed are working properly.

The motors are not connected or it si-

gnals control board failure

Make sure that the motors are properly connected.

If the message reappears change the control board.

The control board power supply voltage

has exceeded the allowed range

Make sure the power supply voltage on the faston

connect. no. 29-30 is 22 V ~+/-10% and on fa-

ston no. 27-28 is 27 V +/-10%.

Possible motor overheating due to ob-

stacles hindering the doors movement.

The control board does not respond to

instructions

Remove any obstacle and wait until the message

“Err6” is replaced by message “bLOC” and the

control board responds to instructions again (a

few seconds)

Summary of Contents for 224RR

Page 1: ......