4

c) When the fryer vessel is filled and the

shortening melted, replace the crumb

screen.

d) Before starting operation, turn the

operating thermostat to the probable

working temperature, wait for the

temperature to stabilize, then check with

a high-quality immersion thermometer.

5. DAILY OPERATION

OPENING:

At opening time, always visually check the fryer

for:

a) Power switch "off".

b) Temperature controller dial "OFF".

GENERAL TURN-ON PROCEDURE:

a) If the fryer is empty, pour enough frying

compound into the fryer to at least cover the

heating elements, or fill the vessel to the "oil

level" line scribed on the rear wall. If solid

shortening is to be used, melt enough in a

separate container to cover the heating

elements in the bottom of the vessel, then

melt the rest in the vessel by turning the

power switch off and on.

b) Turn the power switch on; turn the

temperature controller to 350°F

(recommended). In less than 30 minutes,

the frying compound temperature will

stabilize and be ready for production.

USE OF THE FRYER:

For optimum results, the following general

information is offered.

a) For consistent product quality,

convenience, and long-term savings,

use a high-quality liquid frying

compound.

b) If using solid shortening, never attempt

to melt a block of shortening by setting it

whole in the fryer vessel. This is

inefficient and dangerous.

c) Temperature of frying compound.

Although 350°F is the usual temperature

recommended for most cooking

operations, frying should be carried out

at the lowest temperature which will

produce a high quality and product while

ensuring maximum life of the frying

compound.

When the fryer is not in use, the

temperature controller or operating

thermostat should be set lower than that

used during cooking. Light loads, too,

may be cooked at lower temperatures.

A good operator will experiment to

determine the optimum temperature and

load conditions for the various food

items to be cooked.

d) Salting. Operators sometimes salt the

food over the frying vessel. This

practice should be avoided, as salt

deteriorates the frying compound quickly

and flavors everything being cooked, not

just the batch being salted.

FILTERING:

The frying compound should be filtered at least

daily, or even more frequently if cooking is

heavy. This assures the longest life possible for

the frying compound, gives a better taste to the

food being prepared, and minimizes flavors

being transferred from batch to batch.

When completing a filter cycle, always close the

return valve(s) at the fryer(s) to avoid siphoning

oil out of the fryer into the filter, and open the

WARNING:

The fryer must not be operated without

enough cooking compound in the vessel to

cover the heating elements.

Do not move a fryer filled with a hot liquid.

Always wear oil-proof, insulated gloves

when working with the fryer filled with hot

oil

Always drain hot oil into a metal

container...hot oil can melt plastic buckets

and crack glass on containers.

Summary of Contents for 1414E

Page 11: ...8 PARTS LIST COOL ZONE ELECTRIC FRYERS MODELS 714E 1414E 1818E 2020E ...

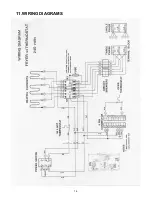

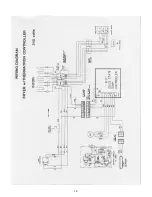

Page 17: ...14 11 WIRING DIAGRAMS ...

Page 18: ...15 ...

Page 19: ...16 ...

Page 20: ...17 ...