19

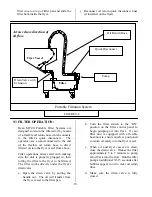

9.4 CHANGING FILTER PAPER:

The top piece of filter paper should be

discarded when it becomes dark or scuffed

in appearance. Follow these procedures:

a.

Before changing the paper, use the

flexible hose (with about one inch of oil

remaining in the filter pan) to flush

debris from the filter pan sides onto the

paper.

b.

Return all oil to the fryer.

c.

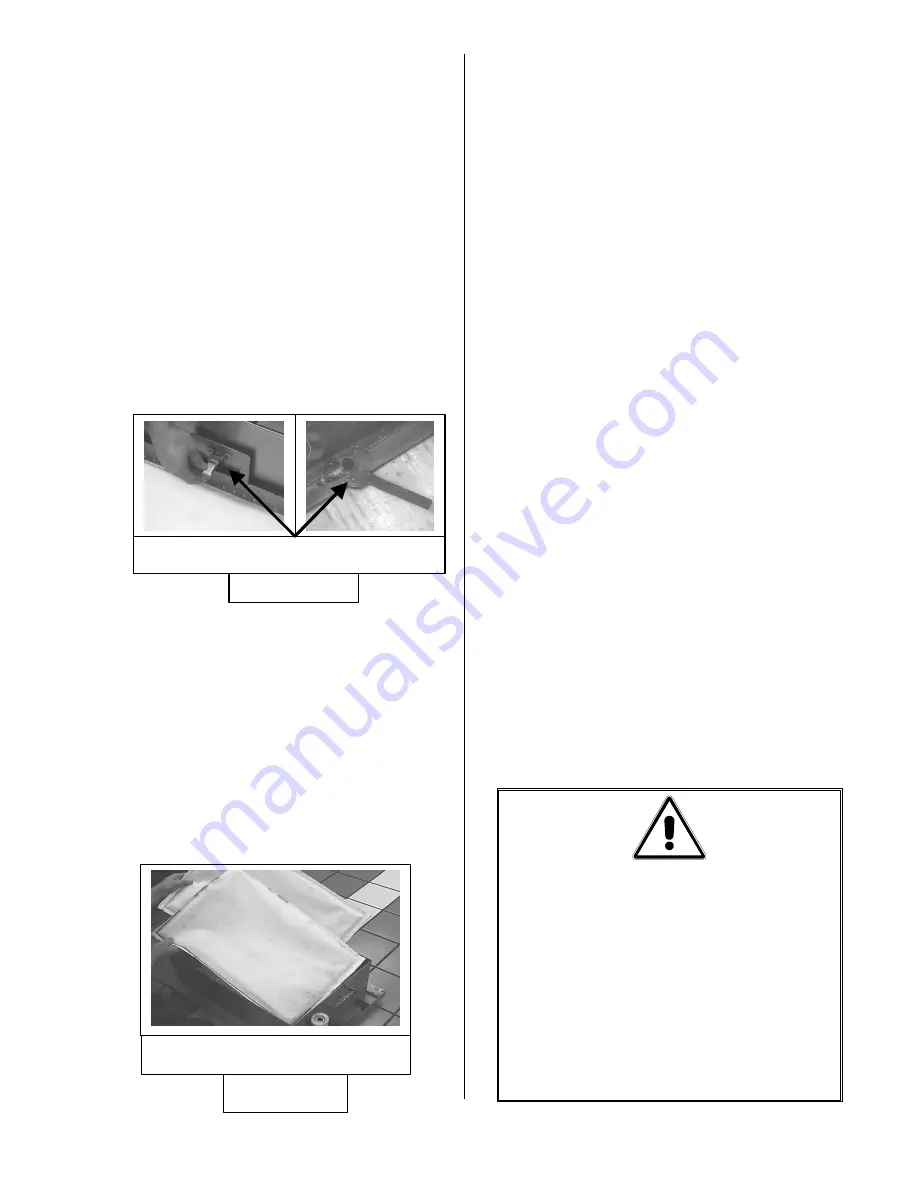

Open the hold-down ring locking

latches and lift the ring out of the filter

tank. Your unit will be equipped with

one of the types shown in figure 9-3.

d.

Roll both ends of the used (top) sheet of

paper in to the center, making sure no

sediment falls out. Discard the top

sheet. Temporarily remove the bottom

sheet and set aside.

e.

Remove and check the support grid for

cleanliness and scrub if necessary.

Check the filter pan for cleanliness and

scrub if necessary. Also check the

drain ports at the bottom rear of the

filter pan for sediment or blockages.

f.

Replace the support grid, lay a new

filter sheet on the grid, then place the

old bottom sheet on top of the new

sheet. It is essential that two sheets of

Dean filter papers are used; use of other

than OEM parts will void the filter

warranty.

g.

Replace the hold-down ring and latch

into position. Sprinkle .45kg (16oz) of

filter powder evenly across the surface

of the filter paper. Re-install the crumb

catcher (if so equipped). Then replace

the filter pan cover.

h.

The unit is now ready for operation.

9.5 FILTER TROUBLESHOOTING:

These troubleshooting procedures must be

carried out only by a Dean Factory

Authorized Service Center or a local

service company specializing in hotel and

restaurant cooking appliances.

The problems and possible solutions given

in this section cover those most commonly

encountered.

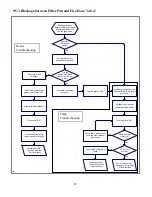

To troubleshoot, perform the test set-up at

the beginning of each condition. Start at

the top of the diagram. Arrows direct the

troubleshooter through the sequence.

Follow each step in sequence as shown in

the troubleshooting diagrams.

Locking Latches

FIGURE 9-3

Installing new filter paper.

FIGURE 9-4

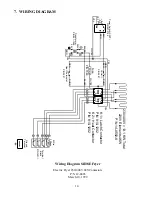

WARNINGS!

INSPECTION, TESTING, AND

REPAIR OF GAS OR ELECTRICAL

EQUIPMENT SHOULD BE

PERFORMED BY QUALIFIED

PERSONNEL.

USE EXTREME

CARE DURING

ELECTRICAL CIRCUIT TESTS. LIVE

CIRCUIT WILL BE EXPOSED.