7

could be toxic and highly acidic. If no acid odor is

present, skip down to the section on changing a

non-burn out compressor.

2. Remove and properly dispose of the system

charge.

DO NOT

vent the refrigerant or allow it to

contact your eyes or skin.

3. Remove the burned out compressor. Use rubber

gloves if there is any possibility of coming in

contact with the oil or sludge.

4. To facilitate subsequent steps, determine the type

of burn out that occurred. If the discharge line

shows no evidence of sludge and the suction line

is also clean or perhaps has some light carbon

deposits, the burn out occurred while the

compressor was not rotating. Contaminants are

therefore largely confined to the compressor

housing. A single installation of liquid and suction

line filter/driers will probably clean up the system.

If sludge is evident in the discharge line, it will

likely be found in the suction line; this indicates

the compressor burned out will running. Sludge

and acid have been pumped throughout the

system. Several changes of the liquid and suction

filter/driers will probably be necessary to cleanse

the system.

5) Correct the system fault that caused the burn out.

Consult the factory for advice.

6) Install the replacement compressor with a new

capacitor and an oversized liquid line filter.

In a running burn out, install an oversized suction

line filter/drier between the accumulator and

compressor. Thoroughly flush the accumulator

with refrigerant to remove all trapped sludge and

to prevent the oil hole from becoming plugged. A

standing burn out does not require a suction line

filter/drier.

7) Evacuate the system with a good vacuum pump

and accurate vacuum gauge. Leave the pump on

the system for at least an hour.

8) Operate the system for a short period of time,

monitoring the suction pressure to determine that

the suction filter is not becoming plugged.

Replace the suction filter/drier if pressure drop

occurs. If a severe running burn out has occurred,

several filter/driers may have to be replaced to

remove all of the acid and moisture.

NOTE: NEVER

use the compressor to evacuate

the system or any part of it.

4.6C Replacing a Compressor- Non-Burn

Out

Remove the refrigerant from the system. Replace the

compressor and liquid line filter/drier. Charge the

system to 50 PSIG and check for leaks. Remove the

charge and weigh in the refrigerant quantity listed on

the nameplate. Operate the system to verify

performance.

4.7 Defrost Thermostat & Timer

The defrost thermostat is attached to the refrigerant

suction tube between the accumulator and

compressor. If the low side refrigerant temperature

drops due to excessive frost formation on the

evaporator coil, the thermostat opens. The

compressor is then cycled off and on by the defrost

timer. The blower will continue to run, causing air to

flow through the evaporator coil and melt the ice when

the compressor is off. When the air temperature and/or

humidity increase, the evaporator temperature will rise

and the thermostat will close to end the defrost cycle.

To improve performance in low temperatures, see Sec.

2.9 for defrost timer adjustment.

4.8 Condensate Pump

Condensate is automatically pumped when the water

level in the pump's reservoir rises to close the float

switch or if the pump purge switch is held in.

If the pump is unable to empty its reservoir due to a

pump failure or blocked condensate hose, a pump

safety float switch is triggered before the reservoir

overflows. The switch turns on the pump fail light &

turns off the compressor via its relay.

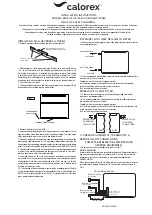

To replace the condensate pump:

1.

Unplug the unit & remove the front cover.

2.

Disconnect the 2 hoses from the pump.

3.

Cut the pump lead wires near the old pump.

4.

Remove the 4 screws from the unit bottom that

hold the pump to the base.

5.

Attach the new pump with 4 screws.

6.

Connect the new pump wiring. It may be easier

to splice the new & old gray leads together with a

wire nut, and splice the new & old yellow leads

together, rather than route the new ones to the

pump purge switch & pump fail light.

7.

Connect the hoses to the new pump. Carefully

route the hoses so they do not contact the

copper refrigerant lines or the compressor shell.