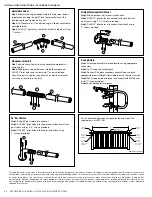

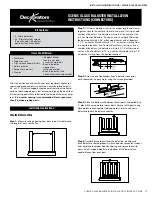

Prior to construction, check with your local regulatory agency

for special code requirements in your area.

Start with an Inside Corner piece when applicable.

Guidelines:

• The height of the secondary handrail must be installed between

34” and 38” above the surface, regardless of the height of the guard.

• We recommend that handrails be dry fit prior to final installation to

eliminate cutting and fastening errors.

• IMPORTANT: The secondary handrail must be attached to a structural

support. When installing mounting brackets on post sleeves, ensure

the hardware attaches to the structural support.

• For maximum strength, brackets should be used at every post and

every joint, or as closely as possible to the joint.

• An adhesive may be applied to further reinforce construction.

• Handrails must be supported every 6’ on-center

by a mounting bracket.

Handrail with Aluminum Insert

Step 1:

Dry fit handrails to determine proper lengths prior to

cutting rails.

Step 2:

Measure and cut rails to proper lengths for all runs.

Step 3:

Install to handrail component, following instructions for the

components.

Items You Will Need

• Drill

• Chop/Miter Saw

• Quick Clamps

• PVC Cleaner

• Pencil

• Tape Measure

• Level

• #2 Square Drive Bit

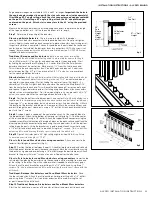

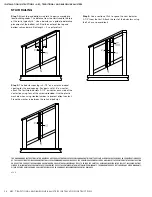

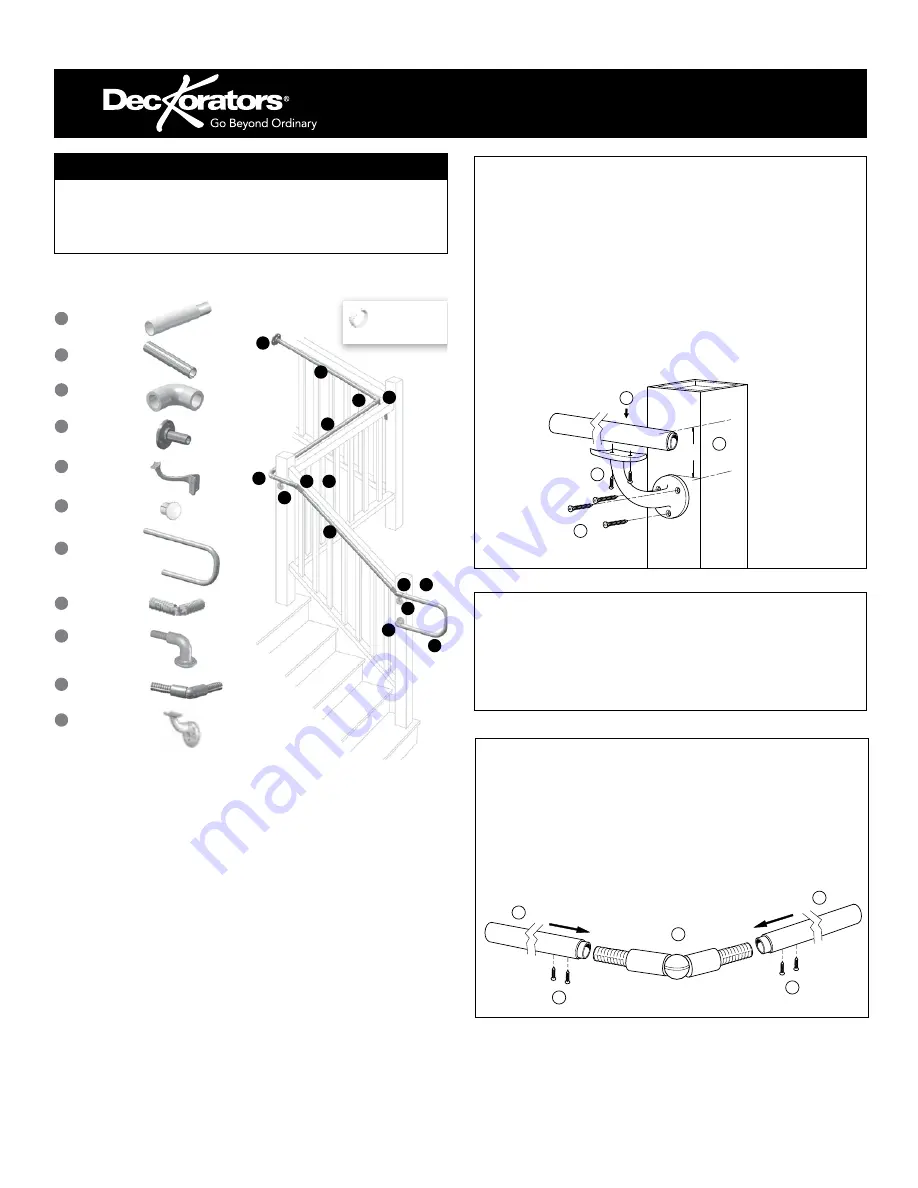

Aluminum Offset Bracket (Line Post Mounting Bracket)

Step 1:

Measure 2-1/2” less than the handrail height to determine

bracket position. Mark surface.

Step 2:

Align the top of the bracket mounting plate with the mark

made in Step 1. Drill 5/32” pilot holes and attach to the desired

surface using the 2-1/4” screws provided.

Step 3:

Clamp handrail to bracket at appropriate location to

secure in place.

Step 4:

Drill 5/32” pilot holes and attach handrail using the 1”

screws provided.

3

4

1

2

2-1/2"

AluminumBracket.ai

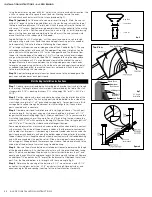

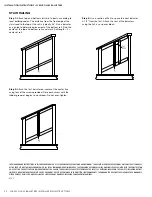

External Swivel

Step 1:

Adjust external swivel to desired angle and install set

screw.

Step 2

: Cut handrail with aluminum insert to desired length.

Step 3:

Insert external swivel bracket into the aluminum portion of

the handrail.

Step 4:

Pre-drill handrail and bracket with 5/32” drill bit and install

1” screw provided.

1

2

4

ExternalSwivel.ai

4

3

End Caps optional

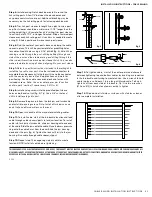

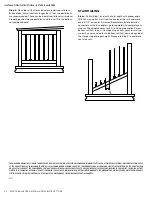

Typical ADA Railing Installation

Components

:

ADA Secondary

Handrail 104"

6" Straight Joiner

4" Inside/Outside

Corner

Straight End Wall

Bracket

Inside Corner Bracket

End Cap

P-Loop Return

6" Adjustable Joiner

90° Quick Return

Bracket

External Swivel

Offset Bracket

1

1

1

1

2

3

3

3

4

4

5

5

6

7

7

8

8

9

9

10

10

11

11

11

or

8

or

10

Optional Beauty Ring

Joint Cover

(Use As Necessary)

ADAinstall314_ADA 4/4/14 9:59 AM Page 2

ADA Compliant Handrail Guidelines and Installation

SECONDARY HANDRAIL INSTALLATION INSTRUCTIONS 47

INSTALLATION INSTRUCTIONS • SECONDARY HANDRAIL