ARC, TRADITIONAL AND BAROQUE BALUSTERS INSTALLATION INSTRUCTIONS 53

INSTALLATION INSTRUCTIONS • ARC, TRADITIONAL AND BAROQUE BALUSTERS

ARC, TRADITIONAL AND BAROQUE

INSTALLATION INSTRUCTIONS

Kit Contents:

• 5 - Balusters for Arc

and Baroque

• 10 - Balusters for

Traditional

• 20 - Color-matched screws

for Arc and Baroque

• 40 - Color-matched

screws for Traditional

• 20 - Baluster end caps for

Traditional (2.5 balusters

required per linear foot

of railing)

Items You Will Need:

• Drill driver

• Tape measure

• 2-pt. square head drill bit

• Safety glasses

• Carpenter’s pencil

• Clamps

• Support blocks

(can be cut from

scrap rail material)

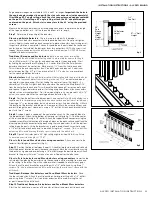

INLINE RAILING

Prior to construction, check with your local regulatory agency for

special code requirements in your area. Common railing height is

36

"

. Structural support should come from either the continuation

of deck support posts that extend up through the deck floor or

from railing posts that are bolted to the inside of the rim or outer

joist.

6' on-center post spacing is recommended. Never span

more than 8' on-center between railing posts.

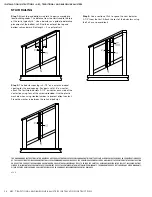

Step 1:

Attach top and bottom rails to posts according to local

building codes. The distance from the deck surface to the top of

the rail is typically 36

"

. Use a baluster as a guide to determine

placement of the bottom rail. Find the center of the top and bottom

rails and mark. Rail length ÷ 2 = center of rail.

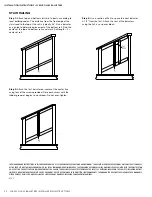

Installation Instructions:

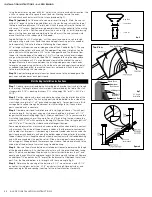

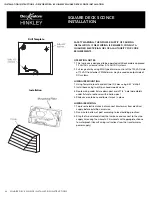

Step 2:

The baluster spacing is 4-1/2

"

on-center and equal spac-

ing for the end spacing. For posts set at 6’ on-center, attach the

first two balusters 2-1/4

"

on-center each side of the center line

using four of the screws provided. Use the plastic washers when

using treated lumber, to prevent direct contact. Place the washer

in between the rail and baluster. When using Traditional balusters,

install the end caps on the hollow ends of each baluster prior to

installing the balusters on the rail.

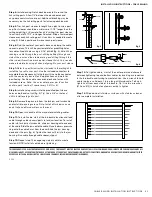

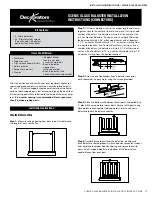

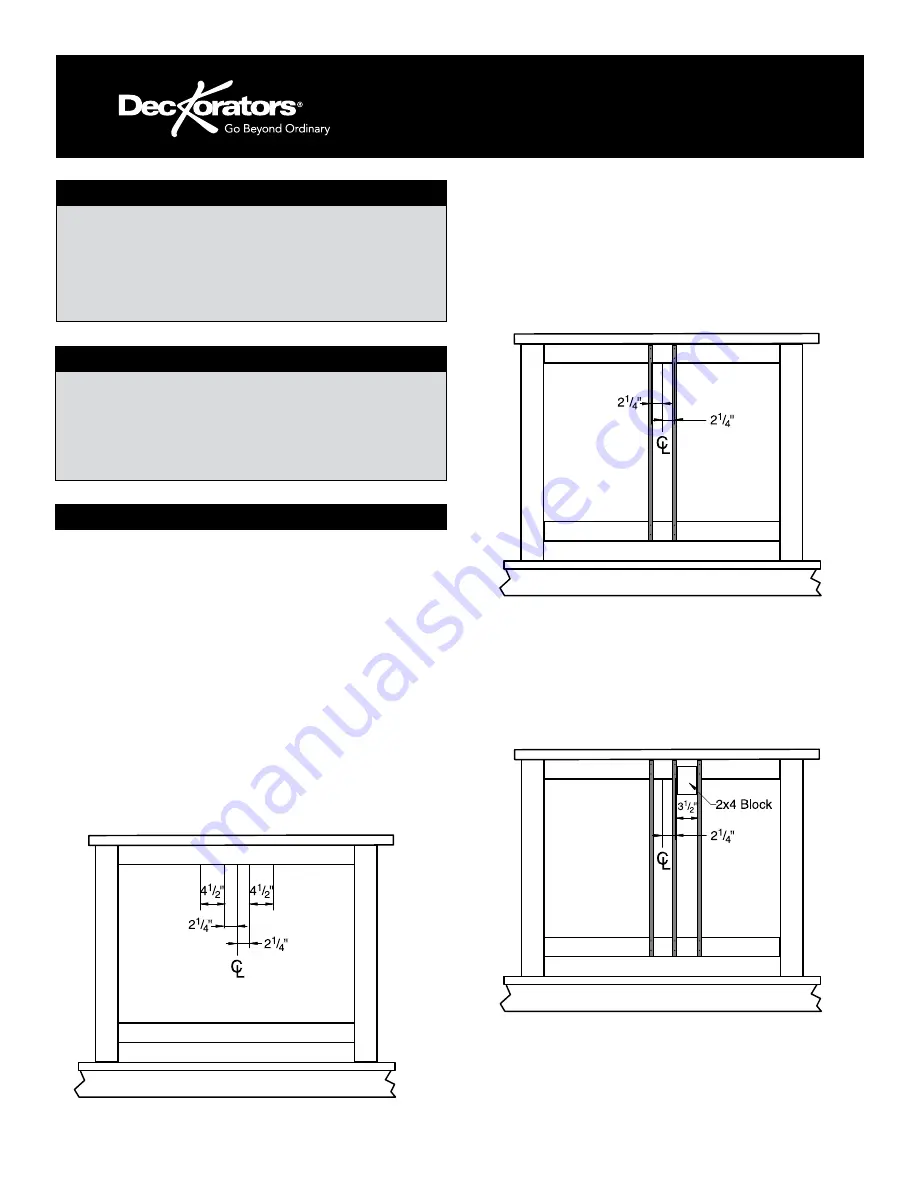

Step 3:

Use a section of 2x4 to space the next baluster 3-1/2

"

from the first. Attach the rest of the balusters using the 2x4 as a

spacer block. Cut two support blocks from the wood or composite

railing material you’re using. Glue support blocks to the bottom of

the lower rail an equal distance from each post.