43

4

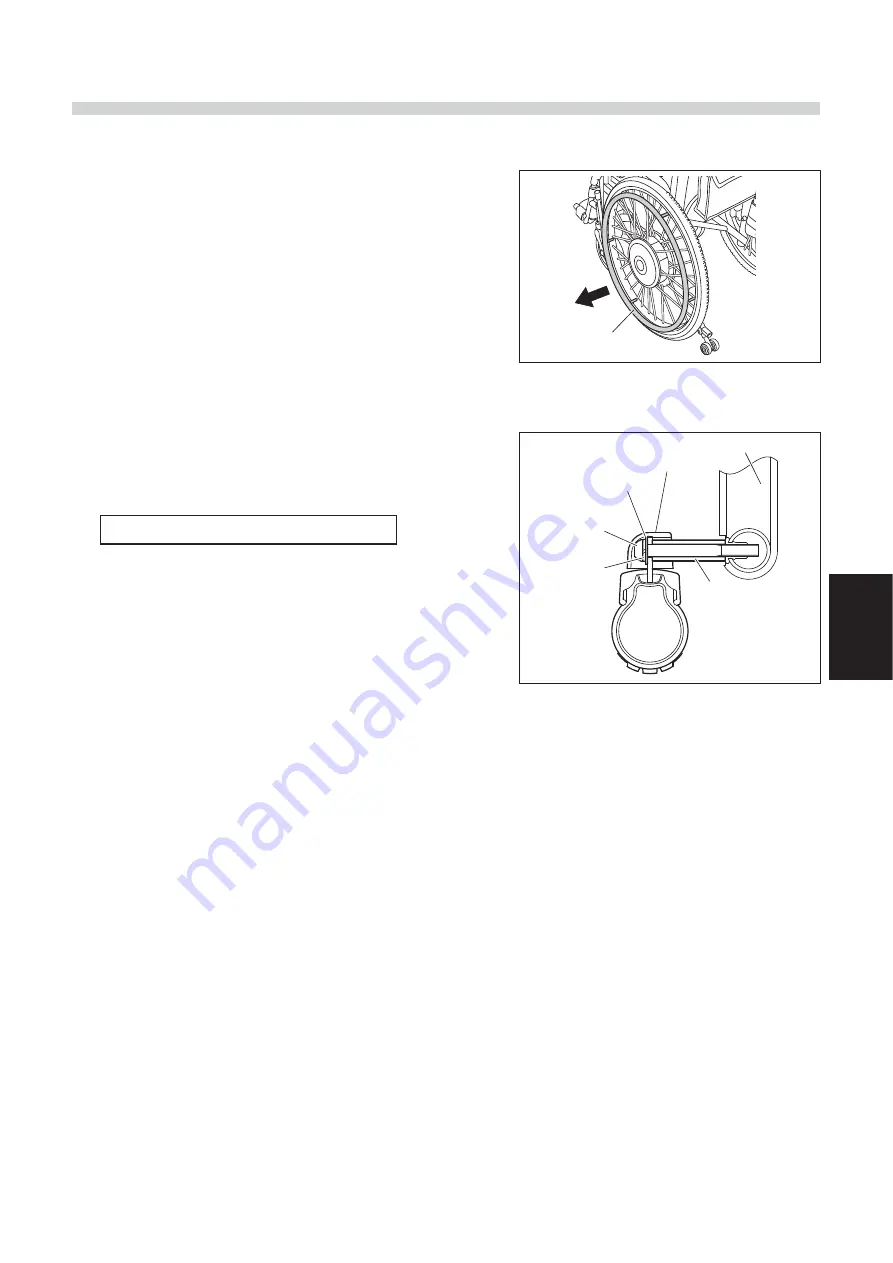

4.4. Hand Rim Replacement (20", 22", and 24" Models)

4.4.1. Hand Rim Removal

4.4.2. Hand Rim Installation

1 Remove the 6 bolt caps.

2 Loosen the bolts with a wrench and remove the

hand rim.

Do not lose the collars, plain washers, and

spring washers because they will be used for the

installation.

1 Temporarily tighten at the 6 locations shown in

the right diagram. Be sure to use the supplied

bolts (with thread-locking agent applied).

2 Tighten the bolts.

Tightening torque: 4 to 5 Nm

Hand rim

Hand rim

Bolt cap

Plain washer

Bolt

Collar

Spring

washer