5.5

Positioning the appliance

5.5.1

Unpacking the appliance

Caution

Remove all packaging materials. Check that the contents are in

tact. If you notice a defect, do not use the appliance and contact

the supplier.

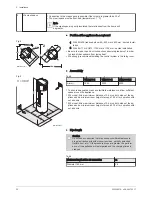

Fig.12

M003102-A

1

2

3

4

5

6

7

8

1. Remove the retaining screw from the fan grille.

2. Turn the grille anticlockwise.

3. Remove the fan grille.

4. Unscrew the two screws from the compressor support part.

5. Remove the compressor support part and discard it.

6. Put the grille back in place.

7. Turn the grille clockwise to fit it back into its housing.

8. Put the retaining screws in place.

5 Installation

300026515 - v09 - 25072017

25