3. Access the PCB.

4. Connect the electrical connection using a cable with a cross section of

1.5 mm

2

.

5.8.4

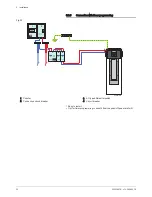

Connection with peak rate/off-peak rate signal connected

shunt connection with peak rate/off-peak rate relay (dry contact

on the peak rate/off-peak rate terminals)

Fig.20

C003617-F

A

A

B

C1 C2

538 kW/h

1

1

A1

A2

0

Auto

0

15 / 45 A

500 mA

TEST

16 A

40 A

2 A

30

mA

L

N

X11-2 HP/H

X11-1 LINE

C

1

2

3

4

4

1 Counter

2 Connection circuit breaker

3 AC-type differential switch

4 Circuit breaker

A 230 V voltage cable, 1.5 mm

2

B Dry contact 1.5 mm

2

(Shunt)

Fig.19

C003335-A

H

P

/H

C

2

3

0

V

C003335-B

5 Installation

30

300026515 - v10 - 28082018