Cleaning the fan

1. Check the cleanliness of the fan once a year. Clogging by dust and

other particles impairs the heat pump's performance.

8.2.4

Impressed current anode

No maintenance operations are required on an impressed current anode.

Important

The control panel for the appliance must remain switched on to

ensure that the impressed current anode can operate. Failure to

comply with this instruction may cause deterioration to the water

heater tank and cancel its warranty.

8.2.5

Checking the safety valve or safety unit

Operate the safety valve or safety unit at least once a month to check that

it is running correctly. This check helps to protect against any pressure

surges that may damage the water heater.

Caution

Failure to comply with this maintenance rule may cause damage

to the water heater tank and invalidate its warranty.

8.2.6

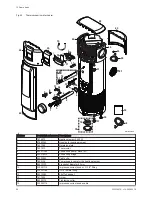

Descaling the thermodynamic water heater

Important

Fit a new leak tight gasket to the inspection hatch.

In hard water regions, you are recommended to ask the installer to

descale the water heater exchanger once a year in order to maintain its

performance levels.

1. Shut off the domestic cold water inlet.

2. Drain the water heater.

3. Turn on a hot water tap.

4. Open the drain valve on the cold water inlet at the bottom of the

domestic hot water tank.

5. Remove the insulation from the inspection hatch.

6. Take out the domestic hot water sensor.

7. Remove the inspection hatch (13-mm spanner).

8. Until December 2015: Remove the two bulbs from the safety

thermostat.

From January 2016: Take out the safety thermostat bulb.

9. Remove the limescale deposited in the tank in the form of sludge or

strips.

Leave the limescale on the walls of the tank: it provides effective

protection against corrosion and enhances the water heater's

insulation.

10. Then replace all the parts in reverse order.

Important

Each time it is opened, the lip gasket must be replaced to

guarantee tightness. Place the positioning lug on the gasket

towards the outside of the water heater.

11. After each intervention, ensure that the installation is watertight.

Important

The screws must be tightened to 6 Nm + 1/-0. Use a torque

wrench.

Fig.41

M002839-B

8 Maintenance

48

300026515 - v10 - 28082018