27

M 300 S

11/2010 - 300003201-001 - F

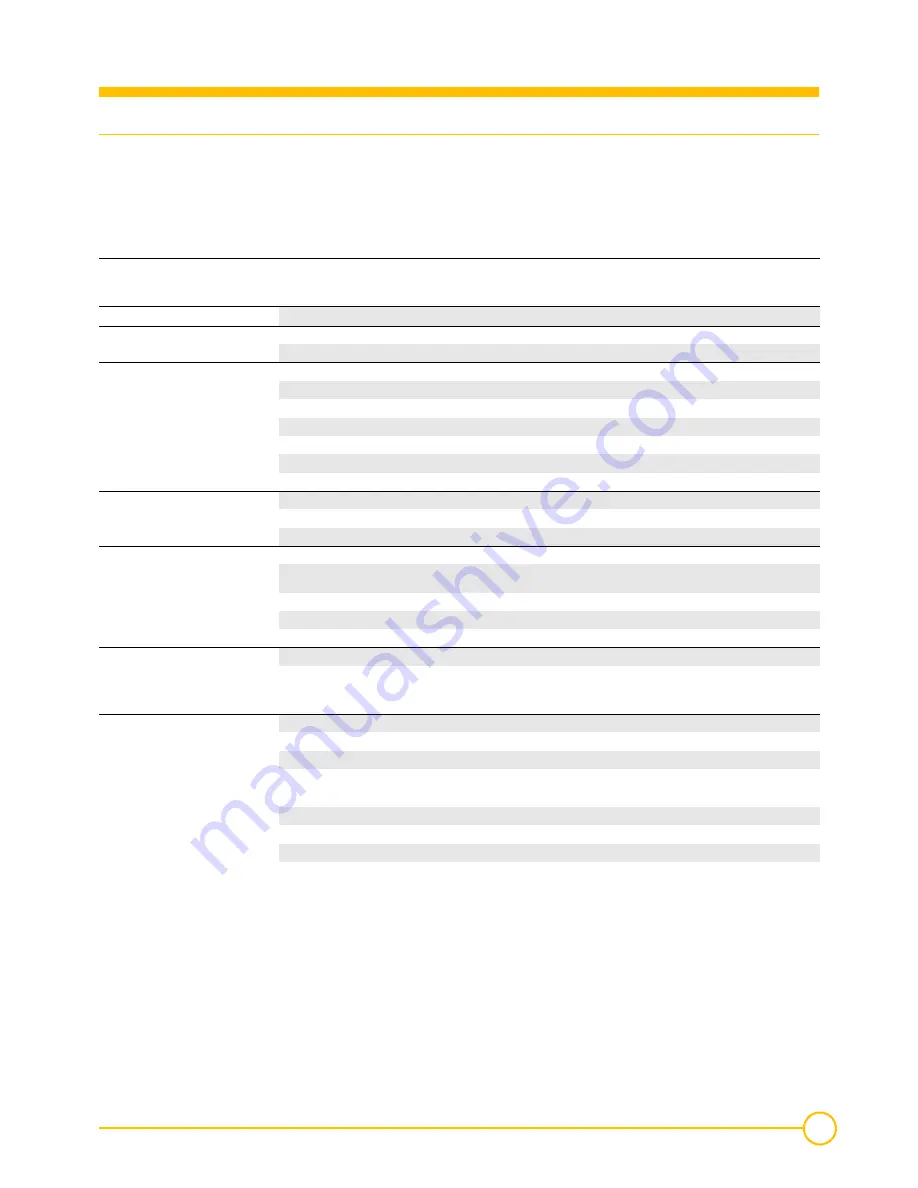

Operating incidents

Prior to any action, the technician must carry out the following checks :

• Are the furnace and the burner receiving voltage (indicator lit, safety thermostat switched on) ?

• Is the fuel-oil supply guaranteed ?

• Are the regulator or the furnace thermostat requesting heat (requesting) ?

• Is the smoke circuit in a good enough condition to allow combustion (Date of last cleaning) ?

Faults

Probable causes

Solution

The burner will not start.

There is no voltage.

Reset the thermostat.

Check the fuses and switches.

Assemble the thermostat or adjustment deposit (set

higher than the furnace temperature).

The motor does not start.

Motor defective.

Replace the motor.

Mechanical noises.

Damaged motor bearings.

Replace the motor.

Turbine friction.

Check its location.

Absence of ignition arch.

Short circuit in the ignition electrodes.

Set the gap between the ignition electrodes.

Ignition electrodes too far apart.

Set the gap between the ignition electrodes.

Dirty, wet electrodes.

Clean or replace the ignition electrodes.

Electrode cable connection fault.

Check the connections.

Ignition electrodes insulation defective.

Replace the electrodes.

Ignition electrode cables defective.

Replace ignition cables.

Transformer defective.

Replace the ignition transformer.

The command box is placed on

safety.

Dirty flame detection cell.

Clean the cell.

The flame is lost.

Correct burner setting.

Flame detection cell defective or cables defective.

Replace cell or cables.

The pump does not aspirate fuel.

Damaged motor/pump coupling.

Replace coupling.

Inlet filter, tubes or pump cover not sealed.

Replace inlet filter.

Tighten joints or cover.

Fuel input - output inverted.

Change the connection.

Retaining valves closed.

Open valves.

Filter or inlet filter obstructed.

Replace filter or inlet filter.

Noises from the pump.

The pump is aspirating air.

Check the seal on the ventilation tube.

The pump is operating on empty.

Clean the filter, see aspiration tube.

Check that the size of the supply tubes is correct, that

there they are not restricted or dirty and that the fuel is not

too cold.

Poor combustion hygiene.

Poor setting.

Check the burner settings.

Lack of air.

Correct air flow.

Dirty or worn nozzle.

Replace nozzle.

Absence of spray.

Connect the electro-valve.

Replace nozzle.

Replacing the pump.

Dirty combustion head

Clean combustion head

Dirty air aspiration routes.

Clean.

Furnace chamber insufficiently ventilated.

Improve ventilation.