DEEKAX Air Oy

Patruunapolku 4 Puh. 0207 912550

79100 LEPPÄVIRTA www.deekaxair.fi

PURE JOY FROM INDOOR AIR !

MAINTENANCE OF TALTERI

For producing good indoor climate continuously, the air exchange systems require regular maintenance.

The metallic grease filter of stove hood must always be kept clean for fire safety reasons. Cleansing with hot

water dishwasher once a month is necessary. Substances suitable for machine washing may darken the

aluminium parts of the filter.

The inlet and outlet filters of Talteri must be cleansed at least twice a year.

In summertime the summer cassette plate will be set to summer mode

when the external air should come in fresh and clean.

The heat recovery cell will be pulled out of the unit and washed thoroughly in autumn just before the heating

season begins –the heat recovery will then be at its best. Check the condition of sealing and push the heat

recovery cell back to its place.

The inner painted walls of the unit are easy to clean. Check the condition of sealing, clean the outlet hose of

condensing water and make sure the water flows freely and without any obstructions.

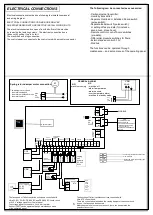

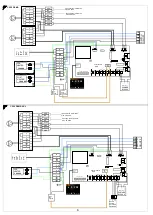

The impellers, air exchange adjusters and thermostats are components that do not require regular

maintenance. Electrical works can be carried out only by a qualified electrician.

During the frosty period the heat recovery cell is defrozen by using the preheater. The power of the

preheater is mainly adequate to keep the heat recovery cell defrozen.

In extreme conditions, if the power of

the preheater is not sufficient, the supply fan power will be reduced or stopped by the freezing protection

thermostat when the exhaust air temperature drops below the set value (0°C). The supply fan starts when

the exhaust air temperature rises above the set value.

Under extreme conditions (humidity /harsh cold) the Ito-element may freeze over and the anti-freeze

protection series are not able to defrost it. If such a case occurs, the machine has to be stopped, opened and

the cold flow stopped and the ice given the necessary time to melt. Check the drainage of condensing water!

In case the water-lock dries out and makes pulping noise, you can pour a drop or two of cooking oil.

In really cold weather, the head recovery unit heats the preheated inlet air with afterheating. The functionality

can be proved by comparing the temperature of inlet air to the set value of the inlet air afterheating.

The overheat protection has been activated in case the temperature has risen +90

o

C (for instance, in case

of power failure). Reset the overheat temperature by pressing the switch under the threaded contact

protection.

The channels must be checked if the impeller works but the air exchange is inadequate or the temperature

changes in the channels between the interior and the machine. Temperature changes and humidity

concentration in channels must be prevented by improving the isolation.