Page 13

x

Secure the hose by tightening the hose clamp.

x

Repeat the same procedure for the other end of

the hose by securing it to the regulator on the gas

bottle to complete the gas cylinder connection.

x

Always check for gas leaks after installation and

whenever a new or refilled gas bottle is used for

the first time.

DANGER Risk of explosion and suf-

focation!

LPG bottles must not be

stored in the house.

x

If this occurs, close the gas bottle valve .

x

Check and tighten the connections immediately.

x

Repeat the procedure to ensure that there are no

further leaks.

Check the general appearance of your

appliance for any damages that might

have occurred during transportation.

Do not place other items on the top of

the appliance. The appliance must be

transported upright.

x

Push the appliance towards the kitchen wall.

Package information

Packaging materials are dangerous to children. Keep

packaging materials in a safe place out of reach of

children.

Packaging materials of the appliance are

manufactured from recyclable materials.

Do not dispose of the packaging materials together

with domestic or other wastes. Dispose of them in a

responsible manner.

Future Transportation

Keep the appliances original carton and transport the

appliance in it. Follow the instructions on the carton. If

you do not have the original carton, pack the

appliance in bubble wrap or thick cardboard and tape

it securely.

To prevent the wire grill and tray inside the oven from

damaging the oven door, place a strip of cardboard

onto the inside of the oven door that lines up with the

position of the trays. Tape the oven door to the side

walls.

Secure the caps and pan supports with adhesive

tape.

Do not use the door or handle to lift or move the

appliance.

Caution:

Never use a naked flame to

check for gas leaks.

DANGER Risk of explosion by

damage of the safety tube!

The safety tube must not be clamped,

bent or trapped or come into contact

with hot parts of the appliance.

Final check

1. Open gas supply.

2. Check gas installations for secure fitting and tight-

ness.

3. Ignite burners and check appearance of the flame.

The flames should be blue and burn

smoothly. If the flames appear

yellowish, check that the burner cap is

seated correctly or clean the burner.

Switch off the gas and let burner cool

before touching it.

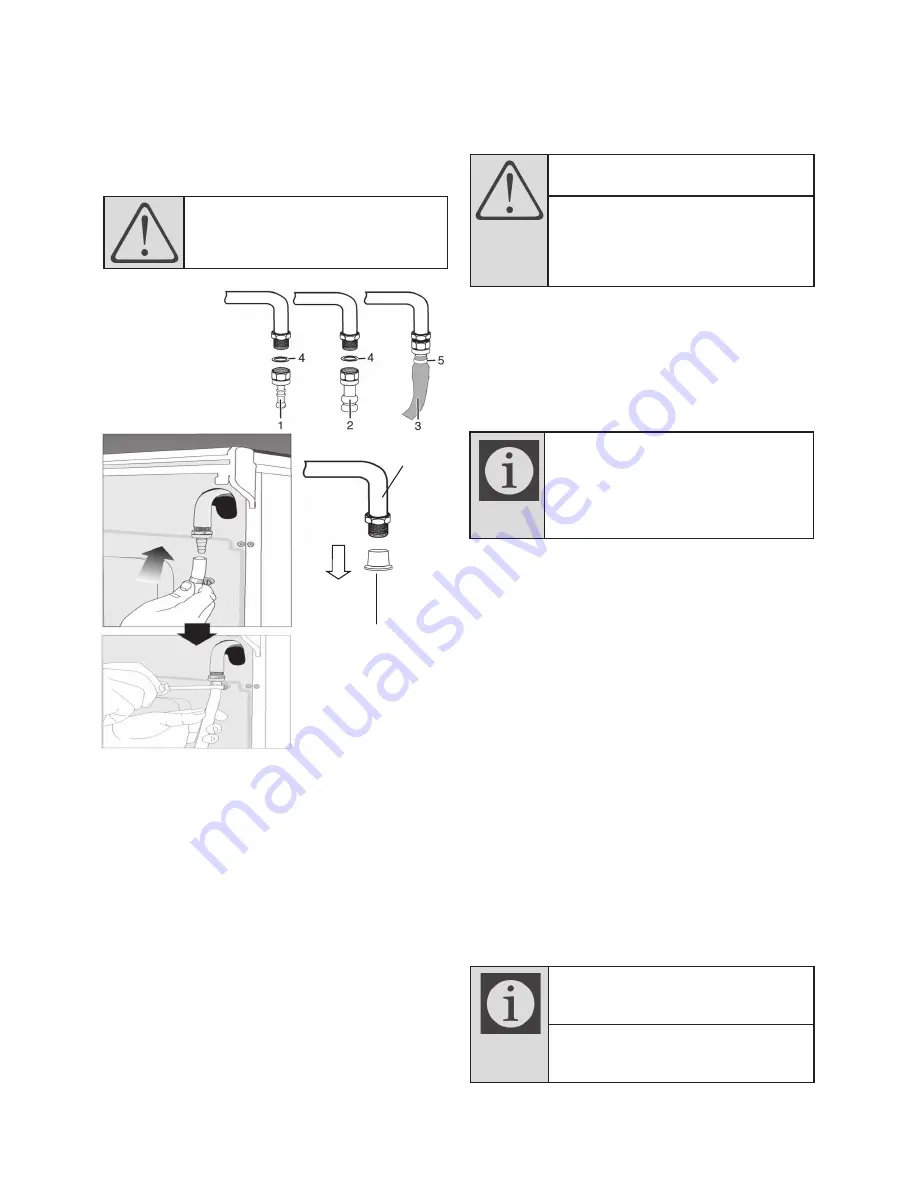

1.

Hose tip-LPG

2.

Hose tip-NG

3.

Safety hose

4.

O-ring (gasket)

5.

Clamp

Manifold

protection

plug

Manifold protector plug removal:

The manifold protection plug is inserted into the

manifold at factory level in order to protect the

manifold from being contaminated with debris. The

manifold protection plug must be removed when the

product is installed by the gas installer.

The red manifold protection plug can be removed

from the manifold by grabbing it with your fingers or if

necessary with the aid of a small pair of pliers.

Manifold

Leakage control at the connection point

x

Ensure that the control knobs on the control panel

are in the OFF position.

x

Open the valve on the Gas bottle.

x

Using a small paint brush, apply some soapy

water to all the connections.

x

If there is a leak, bubbles will appear.

x

If this occurs, close the gas bottle valve .