21

www.degometal.com

5.

MAINTENANCE

SERVICING INSTRUCTIONS

Nose assemblies should be serviced at weekly intervals. You should hold some stock of all

internal components of the nose assembly and nose tips as they will need regular replacement.

• Remove the nose equipment using the reverse procedure to the 'Fitting instructions'.

• Any worn or damaged part should be replaced.

• Clean and check wear on Jaws.

• Ensure that neither the jaw spreader nor the front spring guide is distorted.

• Check spring

7

is not distorted.

Assemble according to fitting instructions above

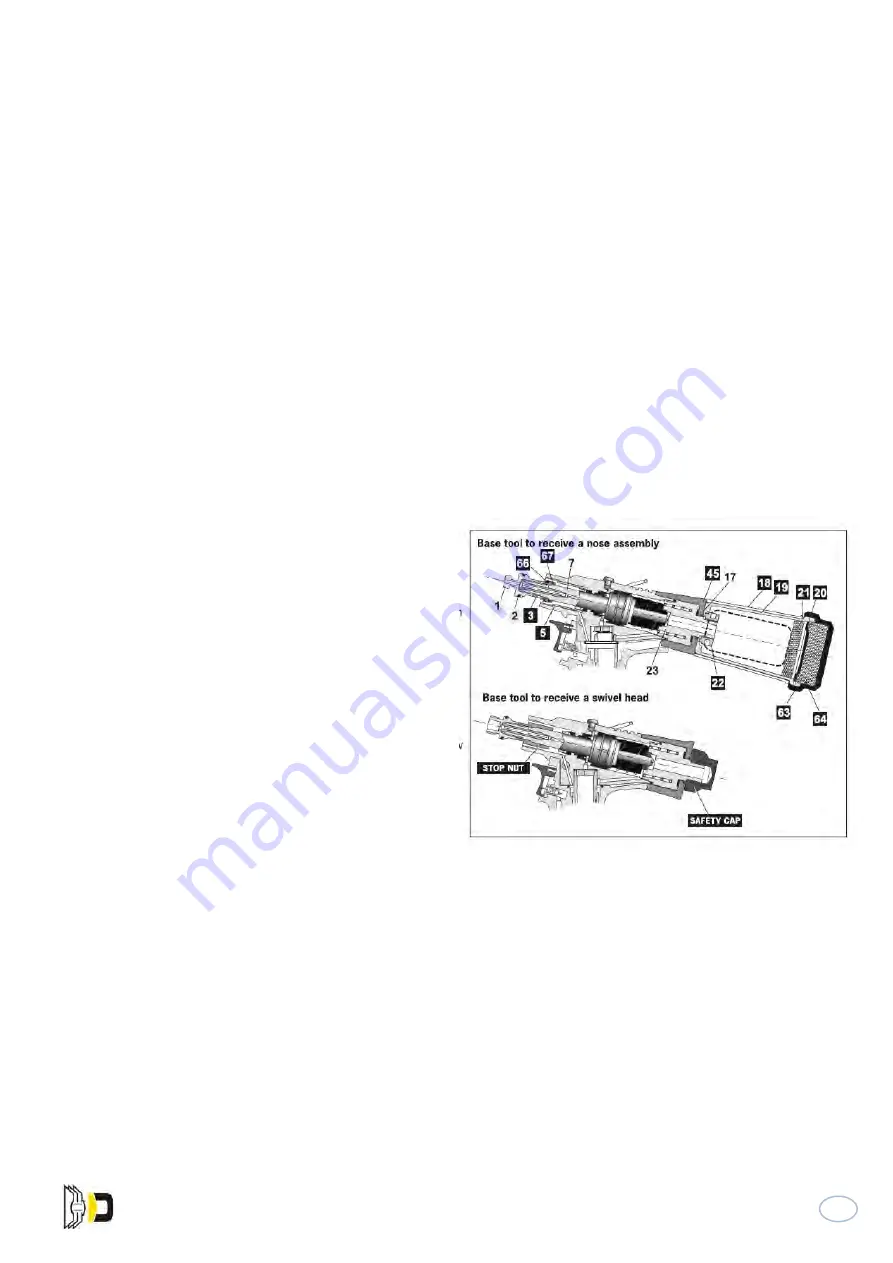

PREPARING THE BASE TOOL:

• Disconnect the air supply.

• Remove any nose assembly items .

• Remove retaining nut

22

and all elements of the stem collector (items

18,19,20,21,45,

63,64).

Note that'O' ring

17

remains.

• Replace the above with a safety cap as

shown in drawing opposite.

• Unscrew jaw spreader housing

1

and

remove with 'O' ring 2,locknut

3,

'O' rings

65

and

66,

and seal housing

5.

• Screw stop nut onto the front of Head Piston

7

as far as it will go by hand.

• Re-fit jaw spreader housing 1 and 'O'ring

2.

• Unscrew the stop nut until it locks against

jaw spreader housing

1

and tighten with

spanner.

The tool is now ready to be fitted with a swivel

head.

IMPORTANT

Read Safety Instructions.

The employer is responsible for ensuring that tool maintenance instructions are given to the

appropriate personnel.

The operator should not be involved in maintenance or repair of the tool unless properly

trained.

The tool shall be examined regularly for damage and malfunction

.

Summary of Contents for GO 182

Page 13: ...13 www degometal com 6 VUE ÉCLATÉE ...

Page 27: ...27 www degometal com 6 EXPLODED DRAWING ...

Page 31: ...31 www degometal com ...