17

4.2

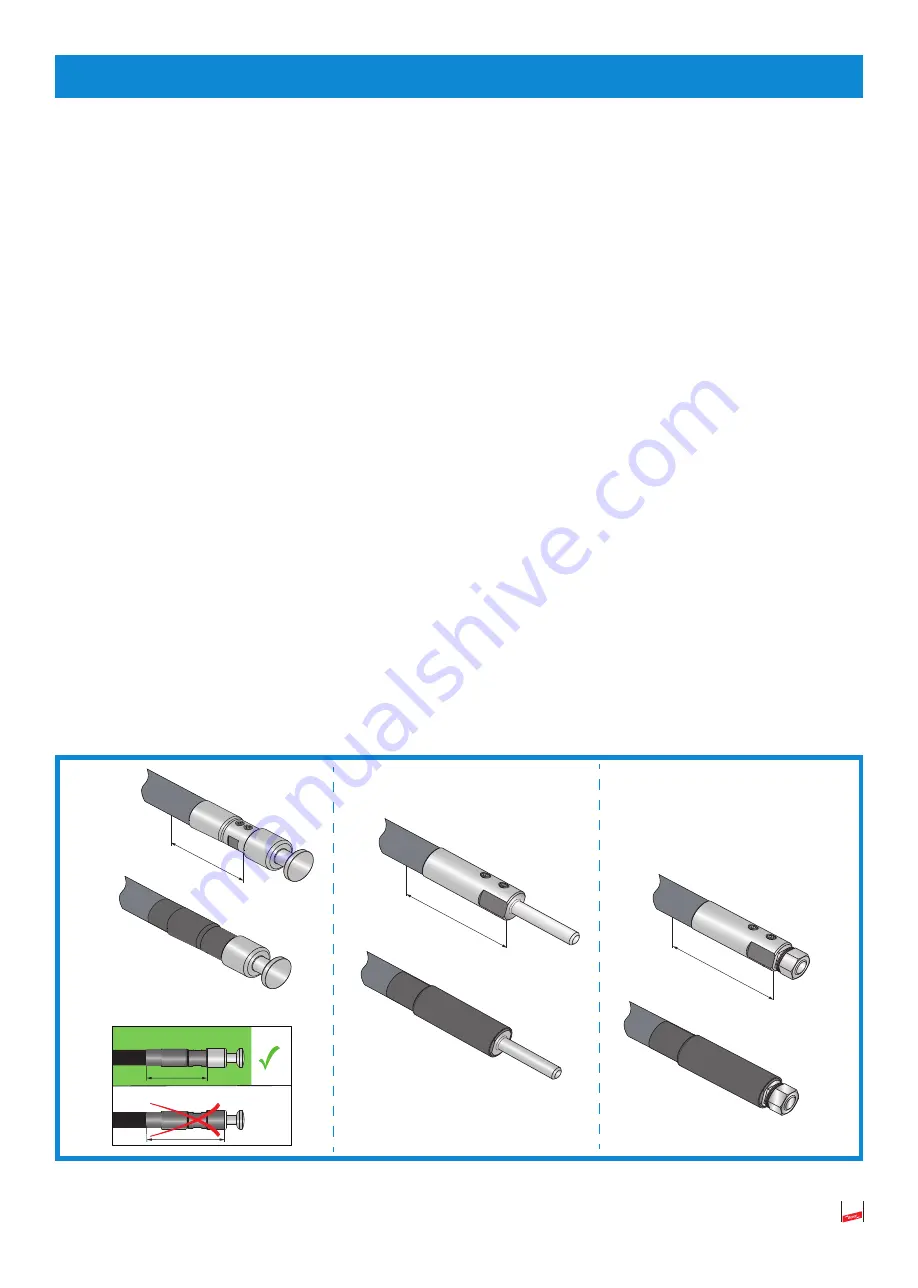

Wrapping a heat shrinkable sleeve around the head piece/connection element

Applying heat shrinkable sleeves

After mounting the head piece/connection element on the

HVI long Conductor

, a heat shrinkable

sleeve must be wrapped around the relevant mounting areas to protect them from mechanical, en-

vironmental or chemical infl uences. One/two heat shrinkable sleeves are available (supplied with the

connection set).

The following must be observed when wrapping a heat shrinkable sleeve around the head

piece/connection element:

Â

The indicated shrinking area from the head piece/connection element to the

HVI Conductor

must

be observed (Fig. 3).

Â

The heat shrinkable sleeve is applied from the front shrinking area of the relevant head piece/

connection element to the

HVI Conductor

. The heat shrinkable sleeves must fl ush with the shrin-

king area. If, required they must be repositioned during the shrinking on process.

Â

The specifi ed shrinking temperature of max. 150 °C must be observed!

Â

The shrinking temperatures in the shrinking area of the

HVI Conductor

must not be too high. In

case of excessive shrinking temperatures, the semiconductive sheath of the

HVI Conductor

can be

damaged or destroyed and the function of the

HVI Conductor

may not be ensured any more.

Â

The heat shrinkable sleeve must not trap air or form bubbles!

Figure 3

Wrapping around a heat shrinkable sleeve around the head piece/connection element

Shrinking area of the

connection element

Shrinking area of the

connection element

Shrinking area of the head

piece

Correct shrinking

Incorrect

shrinking