Storage / Refresh

continued

7. All requested information on “Refresh Record Form” in

Appendix A should be completed for each refresh charge.

8. Cells shall not be stored beyond 12 months. Storing beyond 12

months will affect warranty.

9. If the storage / refresh requirements cannot be met, contact

East Penn Reserve Power Product Support Department for

alternate instructions.

INSTALLATION

General

Caution should be taken when installing batteries to ensure no

damage occurs. The battery string cabinet, tray, rack, etc. shall

be inspected for sharp edges that could cause damage to the

battery casing. Batteries shall not be dropped, slid, or placed on

rough or uneven surfaces such as tray lips or grated flooring.

Mishandling of batteries could result in equipment damage or

human injury. East Penn will not be liable for damage or injury as

a result of mishandling or misuse of the product.

Grounding

When grounding the battery string, proper techniques should be

applied per electrical standards, such as NEC and/or local codes

as well as User Manual of specific application.

Note:

Battery system grounding and/or individual module

grounding, if required, is the installer’s responsibility.

Racks

Assemble racks in accordance with intended arrangement, align

with a level and bolt to floor. Consult applicable rack assembly

instructions for specifics.

Electric Code for Maintenance Access

Refer to ANSI/NFPA-70 National Electric Code for access and

working space requirements around the battery. A minimum of 36"

aisle space is required in front of the battery system for service

and inspection.

Hardware Torque/Retorque Requirements

ELECTRICAL CONNECTION

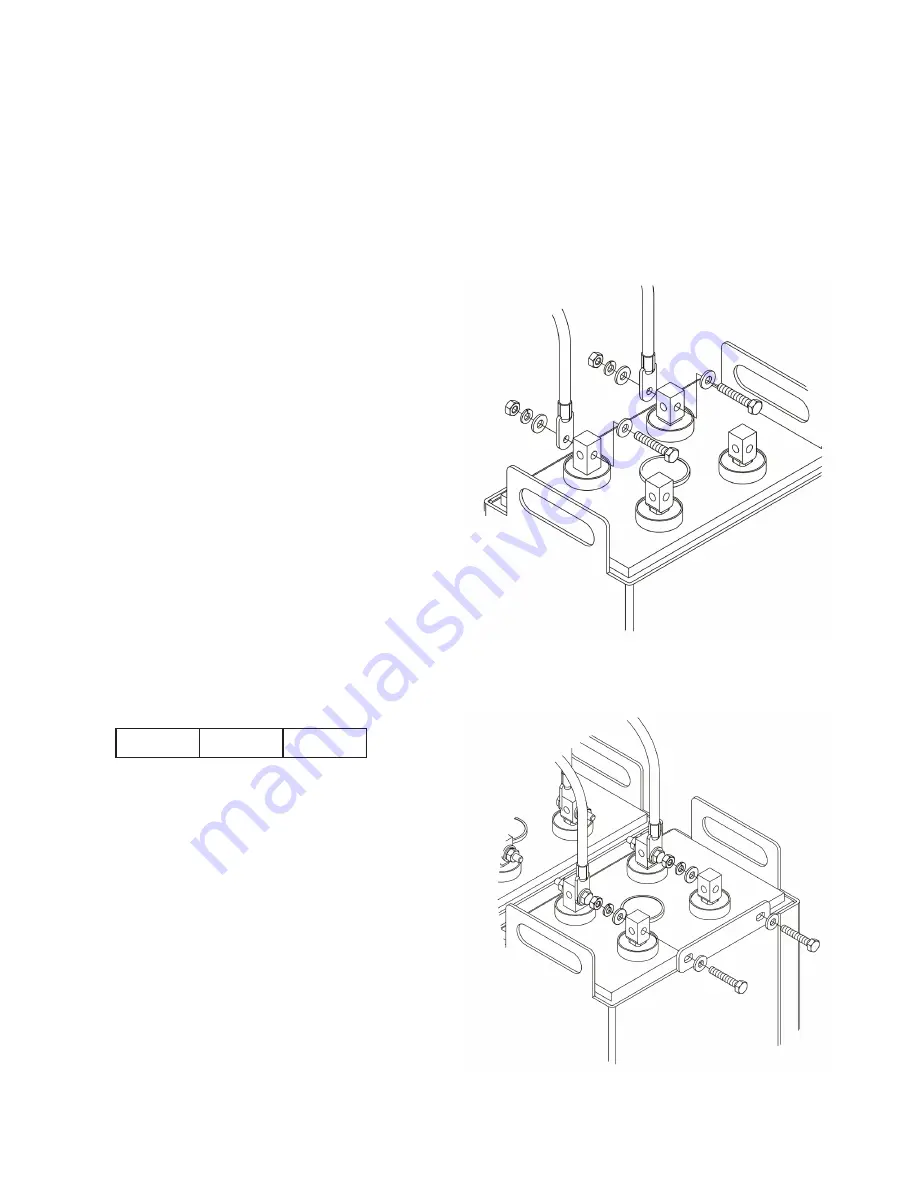

Connector / Cable Assembly

1. The contact surfaces of each individual post on every cell has

been cleaned and coated with a thin film of NO-OX-ID “A”

grease at the factory. Ensure the contact surfaces are free of

dust or dirt prior to assembly. Re-application of NO-OX-ID “A”

grease may be required if post cleaning is required.

2. Connectors/cable lugs supplied with cells. It is recommended

all connectors/cables be coated with a thin film of NO-OX-ID “A”

grease.

3. Install the cables loosely to allow for final alignment. Spacing

between cells should be a minimum of 0.50” (12.7mm) for even

airflow around cells.

4

Bolt Size

Torque / Re-torque

1/4-20

125 in lb

14.1 Nm

SYSTEM INSTALLATION

Cell Installation

Assemble system per the following details.

CAUTION: Never lift more than one cell at a time.

1. Ensure sufficient space has been allowed for proper and safe

battery installation and maintenance.

2. If cells are to be installed on a rack or cabinet, follow rack/

cabinet manufactures instructions for correct installation.

3. Batteries may be installed with posts in a vertical or horizontal

position. When installing in horizontal or vertical position, ensure

battery post are provided with ample clearance from metal parts

of rack/cabinet.

4. For multipost batteries (17 to 33 plate) a connector is to be in-

stalled at the battery system positive and negative end of each

multiple cell configuration. This connector is used to electrically

tie all same polarity posts together.

Summary of Contents for Unigy II AVR45 Series

Page 11: ...APPENDIX E 11 ...