5. Charging / load cable(s) should be tin or lead plated copper lugs

able to accept a 1/4 –20 bolt. Cable lugs should be coated with

a thin film of NO-OX-ID “A” grease. System connecting cables

can be attached to any battery post of the multipost connector.

System connecting cable(s) supplied by others.

Select cable size based on current carrying capability and

voltage drop.

Select cable size based on current carrying capability and

voltage drop.

Cable size should not provide a greater voltage drop between the

battery string and operating equipment than required. Excessive

voltage drop in cables will reduce the desired reserve time and

power from the battery string.

Cable sizing is the responsibility of site electrical engineer.

SYSTEM OPERATIONS

Charger Voltage

2.25 V per battery ± 0.01 @ 77°F (25°C)

When setting the float voltage on the charger, the battery string

should be set to float at the required cell float voltage times the

number of cells per battery string. The charger must be able to

maintain the battery string voltage within ± 0.5% of the desired

level at all times.

Charge Current

Charge current should not exceed the recommended minimum

and maximum requirements as detailed in Appendix C.

Temperature Compensation

Battery voltage should be adjusted for ambient

temperature variations.

2mV per °C (1.8°F) per 2V cell.

Consult

Voltage Compensation Chart (Appendix C)

for

temperature compensation voltage maximum and minimum limits.

Cell Voltage

Although the charger must maintain the battery string voltage

within ± 0.5%, individual cell voltages may vary by ± 0.05 volts

of the average cell float voltage.

Equalizing

Upon installation of the battery string, an optional charge at a

constant voltage equal to 2.40V per cell ± 0.01 @ 77°F (25°C)

for a maximum of 24hrs may be performed. (NOTE: Verify that the

higher cell voltage will not adversely affect any other connected

equipment). If this is done, be sure to reset the charging equip-

ment to the proper float voltage.

Battery Operation

Battery string operating temperature will affect battery string

capacity and operating life.

Temperatures greater than 77°F (25°C) will reduce the operating

life of the battery. For every 13°F (7°C) increase in operating

temperature above 77°F (25°C), the warranty period will be

proportionally reduced by 50% as shown below:

5

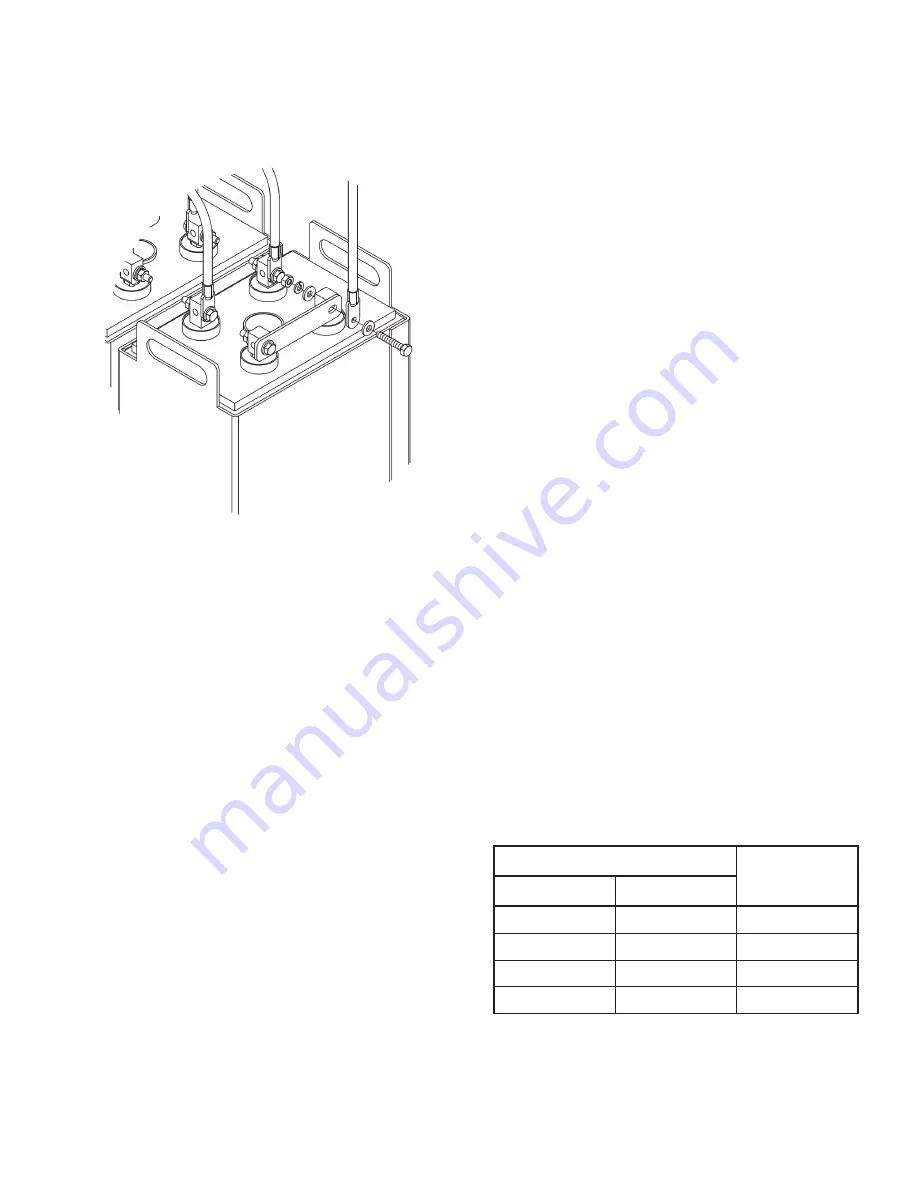

6. Reference Appendix D for layout drawings detailing cable and

connector quantity and placement.

7. Upon completion of installing, all connectors / cables hardware

should be torqued to 125 ± 5 inch pounds (14.1 ± .5 Nm).

Final Assembly Check Procedure

1. For future identification of all cells, number individual cells in

sequence, beginning with number one (1) at the positive end of

the battery. The last cell of the battery string is located at the

negative output terminal.

2. Read and record the voltages of the cells to assure that they are

connected properly. The total battery string voltage should be

approximately equal to the number of cells connected in series

multiplied by the measured voltage of one cell. If the measure-

ment is less, recheck the connections for proper polarity. Verify

that all cell and battery string connections have been properly

torqued.

3. Measure and record the intercell connection resistance using a

micro-ohms meter. This helps determine the adequacy of ini-

tial connection installation and can be used as a reference for

future maintenance requirements. Refer to the recording forms

in Battery Maintenance Report in Appendix E of this manual.

Review the records of each connection and detail resistance

measurements. Clean, remake, and re-measure any connection

that has a resistance measurement greater than 10% of the

average of all the same type connections (i.e. intercell, inter-

module, etc.).

4. Battery string performance is based on the output at the battery

terminals. Therefore, the shortest electrical connection between

the battery system and the operating equipment results in maxi-

mum total system performance.

Operating Temperature

Proportional

Percentage (%)

of Life

ºF

ºC

77º

25º

100%

81º

27º

80%

87º

30º

60%

90º

32º

50%

It is not recommended to operate the battery string above 95°F

(35°C). If operating temperatures are expected to be in excess of

95°F (35°C), contact East Penn for recommendations. Operating

a battery string over 105°F (40.5°C) for more than 8 hours may

void warranty.

Summary of Contents for Unigy II AVR45 Series

Page 11: ...APPENDIX E 11 ...