DEKKER Vacuum Technologies, Inc. – HullVac / September 2016

17

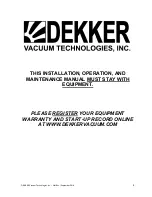

8

Confirm the oil solenoid valve is open. The valve’s

solenoid coil is energized whenever the motor is

energized. During initial operation, confirm valve

operation by holding a screw driver or other

metal object close to, but not touching the valve

stem top. If the coil is energized, a gentle tugging

or vibration will be detected. An oil stream will

also be present on the oil level site port whenever

the pump is in operation. If an oil stream or splash

is not present, check the solenoid valve for

proper operation.

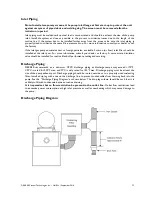

9

The oil level should be checked after the pump

has been operating at an inlet pressure below 1

torr for 5 minutes. Proper oil fill is confirmed

when the site port oil level is at least ½ level.

During initial evacuation, the site port oil level

may rise but will fall as the pump operates below

1 torr.

During operation, oil should always be visible in

the site port. If it is not, stop the pump and add

oil to the reservoir until it is visible around two-

thirds up the oil site port. An exact fill level is not

required as long as oil is always at least ½ level in

the site port, throughout all operating conditions.

An oil fill level above the site port should be

avoided as it will be difficult to verify correct fill

level and could damage the pump.

10

Check the voltage and motor current. They

should be within the specifications for the motor.

Note:

This test should also be performed under

normal system operating conditions.

DANGER: HIGH VOLTAGE!

Lethal shock hazard present.

USE EXTREME CAUTION!