DEKKER Vacuum Technologies, Inc. – HullVac / September 2016

21

Every 5 Years

Replace the bearings, shaft seals, shaft seal wear sleeves, and o-rings.

Replace the oil flow solenoid valve wear components.

Replace the gas ballast valves.

MAINTENANCE

WARNING: Before attempting any maintenance such as changing the fluid, disconnect all

power from the system by switching off the main breaker or disconnect switch. This will

prevent the system from automatically starting from a vacuum switch.

Seal Fluid/Oil

The product(s) are shipped with DEKKER’s specially formulated

HullVac

seal fluid (hereafter referred to

as oil). DEKKER recommends that this oil be used to obtain the ultimate performance from the

HullVac

product and to maintain the 3-year warranty period.

Oil should be changed whenever it appears white or yellow, foams consistently, or when dirty. Oil change

frequency depends on the materials being pumped. For clean operation, oil should be changed every 3000

operating hours or every 9 months, whichever comes first. For other operation, oil change could range

from once or twice a week or less dependent upon the type of application.

The most common contamination is water in the oil and can be recognized by a milky appearance visible in

the site port. Closing the pump inlet valve and operating the gas ballast valves for 2 to 4 hours can remove

this water. If this does not clear the oil, change it. In applications with consistent water accumulation,

draining the water from the reservoir prior to operation is recommended.

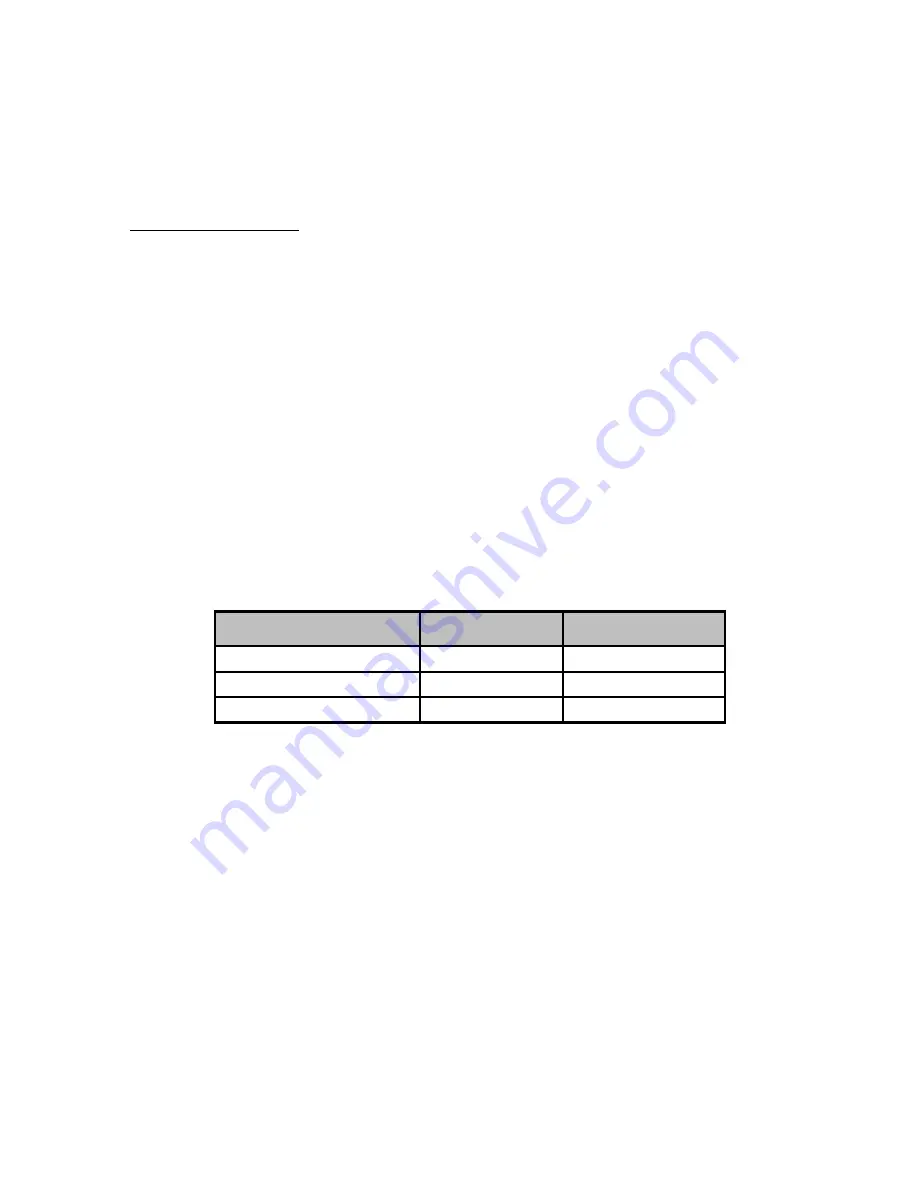

HullVac Oil

Container Size

Standard

Water Application

1 Gallon Container

5120-0010-002

5120-0010-003

5 Gallon Container

5120-0050-000

5120-0050-008

55 Gallon Drum

5120-0550-000

5120-0550-002

Safety Data Sheets (SDS) available upon request.