DEKKER Vacuum Technologies, Inc. – HullVac / September 2016

9

Location

Install the unit in a well ventilated and dust free area. The pump or system should be a minimum distance of

3 feet from surrounding walls and other equipment to allow for inspection, service, belt tightening, and oil

changes.

Mounting

The pump or system must be installed on a level surface. The foundation, typically a concrete pad, must be

designed to support the total unit operating weight, without any settlement or crushing. It must also be

rigid and substantial enough to absorb any equipment vibration, and must permanently support the system

baseplate or pump at all points. Mount the pump using concrete anchors.

If the pump is mounted to a baseplate, the baseplate must be leveled and secured with foundation bolts.

Foundation bolts must be of adequate size to withstand the mechanical stresses exerted on them. The

baseplate must be grouted if the total weight is over 5,000 lbs.

Ventilation/Cooling

Locate the vacuum system in an area with sufficient airflow and accessibility. To prevent excessive ambient

temperature rise, it is imperative to provide adequate ventilation. Cooling is an important aspect of reliable

equipment operation and it is therefore important to install the unit in a reasonably cool area where the

temperature does not exceed 104°F. For higher ambient temperatures contact the factory.

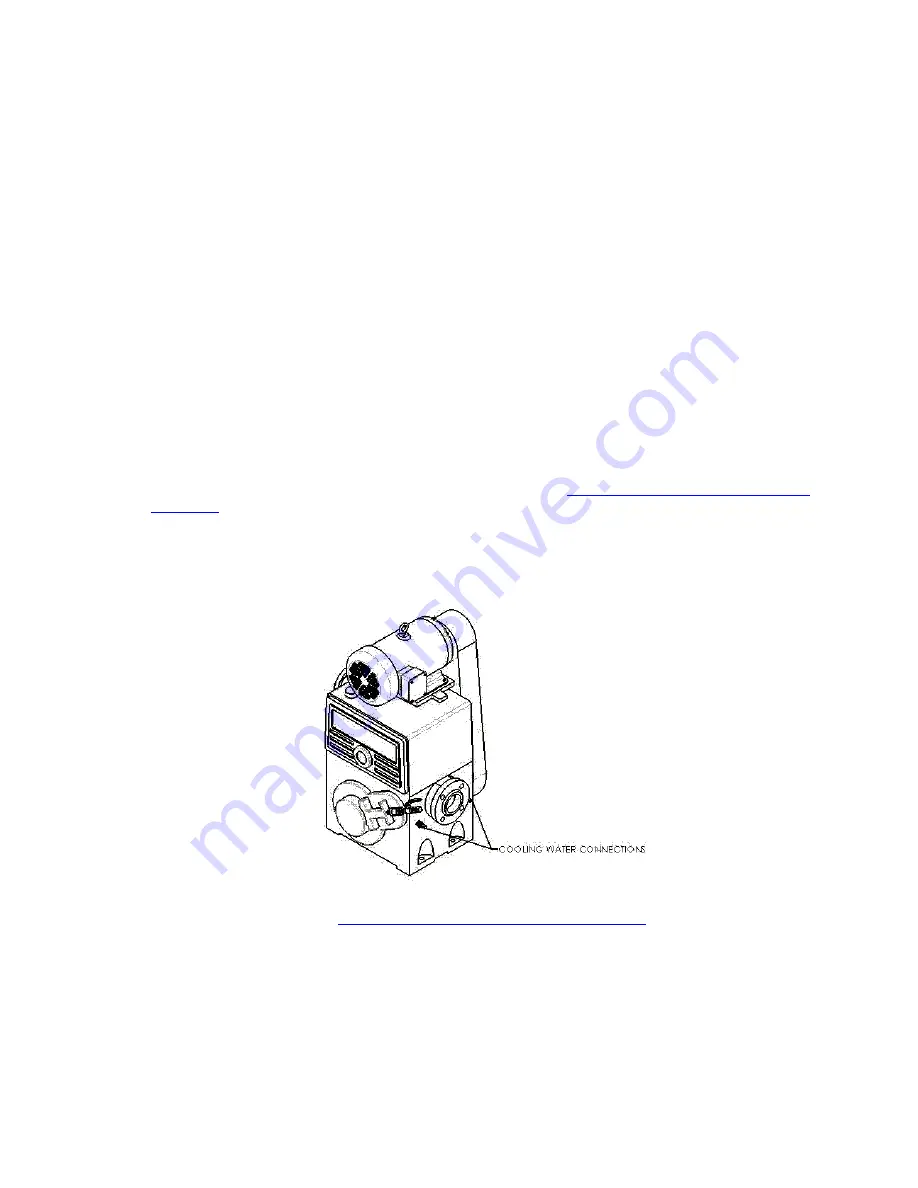

For water-cooled vacuum systems, it is necessary to check cooling water supply. A proper, consistent

water flow must be maintained for adequate cooling. Refer to the

Cooling Capacities and Port Sizes table

for recommended cooling water capacities at 40°F based on standard operation. A water miser

valve that automatically regulates water flow is recommended.

Water jacket pressure must not exceed 30 psig.

The water inlet and water outlet ports require National Pipe Thread (NPT) fittings and are located below

the vacuum inlet. Refer to the

Cooling Capacities and Port Sizes table on page 10

are interchangeable, however if a water miser valve is installed it must be on the water outlet port.

Normal system operating temperature is between 140-160°F as measured on the oil solenoid valve body

located below the exhaust port. Pump casing temperature should not exceed 180°F. If excessive

temperature is measured, increase the cooling water flow. Maximum cooling water supply temperature

should not exceed 85°F.

Oil temperature should be maintained at 165°F. Minimum oil temperature should not be below 55°F. The

increased sealing oil viscosity caused by low temperature can lead to internal galling and motor overload

fault.