18600 and CTP-NB Series Service and Installation Manual

11

The factory recommended low-pressure control settings

for 18600PTB’s are:

55psi cut-in and 30psi cut-out to

maintain proper temperature for product in the rail. The

interior temperature is controlled by the thermostat mounted

in the mechanical compartment.

The factory recommended low-pressure control settings

for 18600PTL’s are:

20psi (1.38bar) cut-in and 10psi

(0.70bar) cut-out. The base and rail temperatures are

controlled by the thermostats mounted in the machine

compartment.

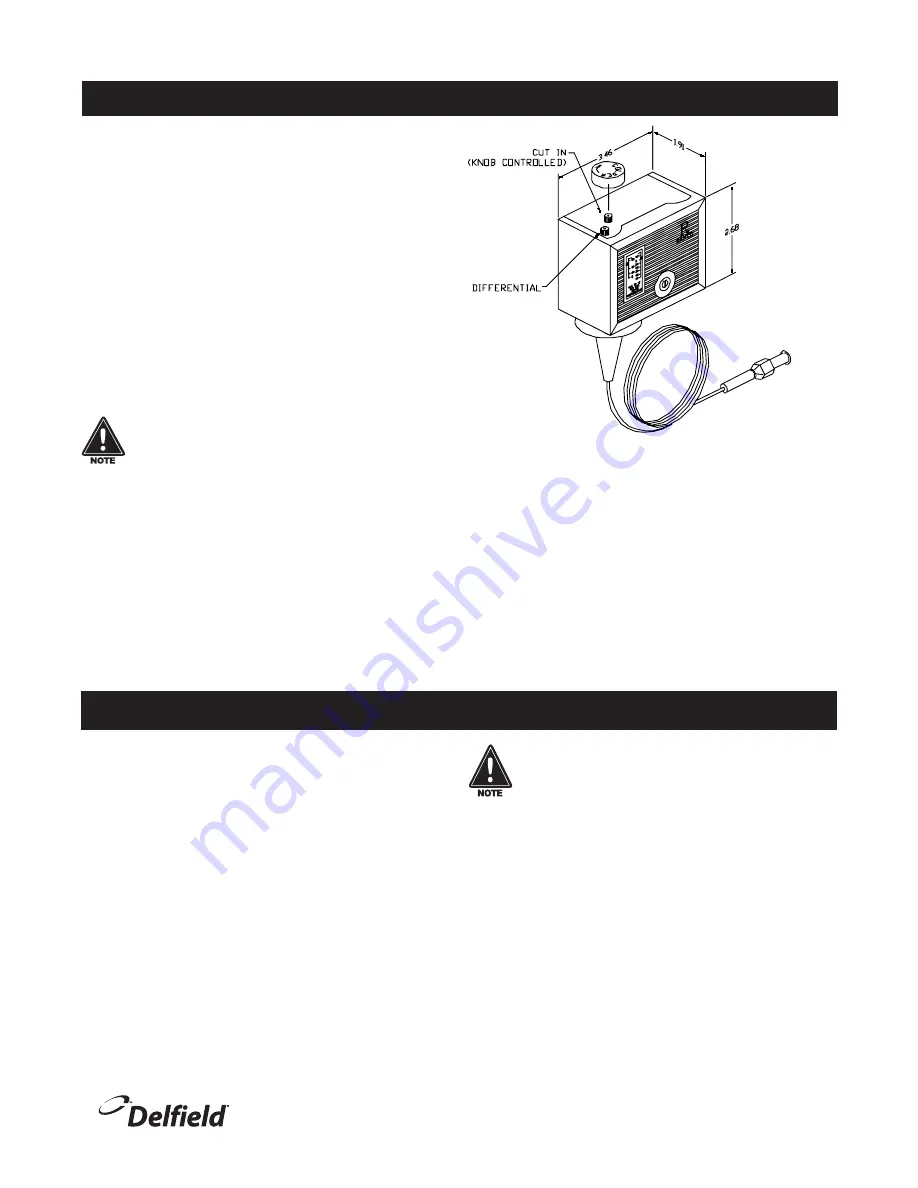

A pressure control is located in the machine compartment.

An adjustable control has the word COLDER on the knob,

with an arrow to indicate the adjustment direction. These

controls are field adjustable and do not require a service

agent.

In attempting to adjust the pressure control,

you can do damage to your unit by accidentally

adjusting the differential. Please make small

incremental adjustments if a temperature

adjustment is necessary. It may take an hour

or longer to realize the temperature change

depending on the application and location of the

unit.

Please contact KitchenCare 1 (844) 724-2273

or your local service agent. Delfield is not

responsible for charges incurred while having the

pressure control adjusted.

Pressure Control Settings

Temperature Control Settings

A thermostat controls temperature in the 18600PTB base,

18600PTL base, 18600PTL rail, BUC, BST, 18600PDL base

and 18600PDL rail.

Thermostats are located in the machine compartment. They

are field adjustable and do not require a service agent. The

factory setting is 2.5. Set toward 1 for higher temperatures

and toward 7 for lower temperatures.

Please make small incremental adjustments if

a temperature adjustment is necessary. It may

take an hour or longer to realize the temperature

change depending on the application and location

of the unit.

Contact KitchenCare 1 (844) 724-2273 or your

local service agent for additional assistance.

Delfield is not responsible for charges incurred

while adjusting the thermostat.