F13 Series Ice Cream Cabinets Service and Installation Manual

For customer service, call (800) 733-8829, (800) 773-8821, (989) 773-7981, Fax (989) 773-3210, www.delfield.com

4

OPERATION

MAINTENANCE

Cleaning

The interior and exterior can be cleaned using soap and warm water.

If this is not sufficient, try ammonia and water or non-abrasive liquid

cleaner. When cleaning the exterior, always rub with the “grain” of

the stainless steel to avoid marring the finish. Do not use an abrasive

cleaner because it will scratch the stainless steel and plastic.

In order to maintain proper refrigeration performance, the condenser

fins must be cleaned of dust, dirt, and grease regularly. It is

recommended that this be done at least every three months. If

conditions are such that the condenser is totally blocked in three

months, the frequency of cleaning should be increased. Clean the

condenser with a vacuum cleaner or stiff brush. If extremely dirty, a

commercially available condenser cleaner may be required.

The compartment lids should be cleaned as required to maintain their

ability to seal properly. A bristle brush and solution of soap and water

should be all that is required to keep the lids clean. Do not use full

strength degreasing agents on the rubber parts as they can cause the

rubber to crack and become brittle.

Cleaning solutions need to be alkaline based or non-chloride

cleaners. Any cleaner containing chlorides will damage the

protective film of the stainless steel. Chlorides are also commonly

found in hard water, salts, and household and industrial cleaners. If

cleaners containing chlorides are used be sure to rinse repeatedly

and dry thoroughly upon completion. Routine cleaning of stainless

steel can be done with soap and water. Extreme stains or grease

should be cleaned with a non-abrasive cleaner and plastic scrub

pad. It is always good to rub with the grain of the steel. There

are also stainless steel cleaners available which can restore and

preserve the finish of the steels protective layer. Early signs of

stainless steel breakdown can consist of small pits and cracks. If

this has begun, clean thoroughly and start to apply stainless steel

cleaners in attempt to restore the passivity of the steel.

Defrosting

These units do not have an automatic defrost system. Defrosting

must be done manually after 3/8” frost accumulation. To defrost, turn

the power switch to OFF. Allow the frost to melt and mop up with a

sponge or soft cloth. When the defrost is complete, turn the power

switch back to ON.

Do not use sharp utensils to scrape frost because they

can damage important refrigeration components and

scratch or dent the liner.

Expansion Valve Location

The expansion valve location for remote and self-contained models is

located in the machine compartment of the unit.

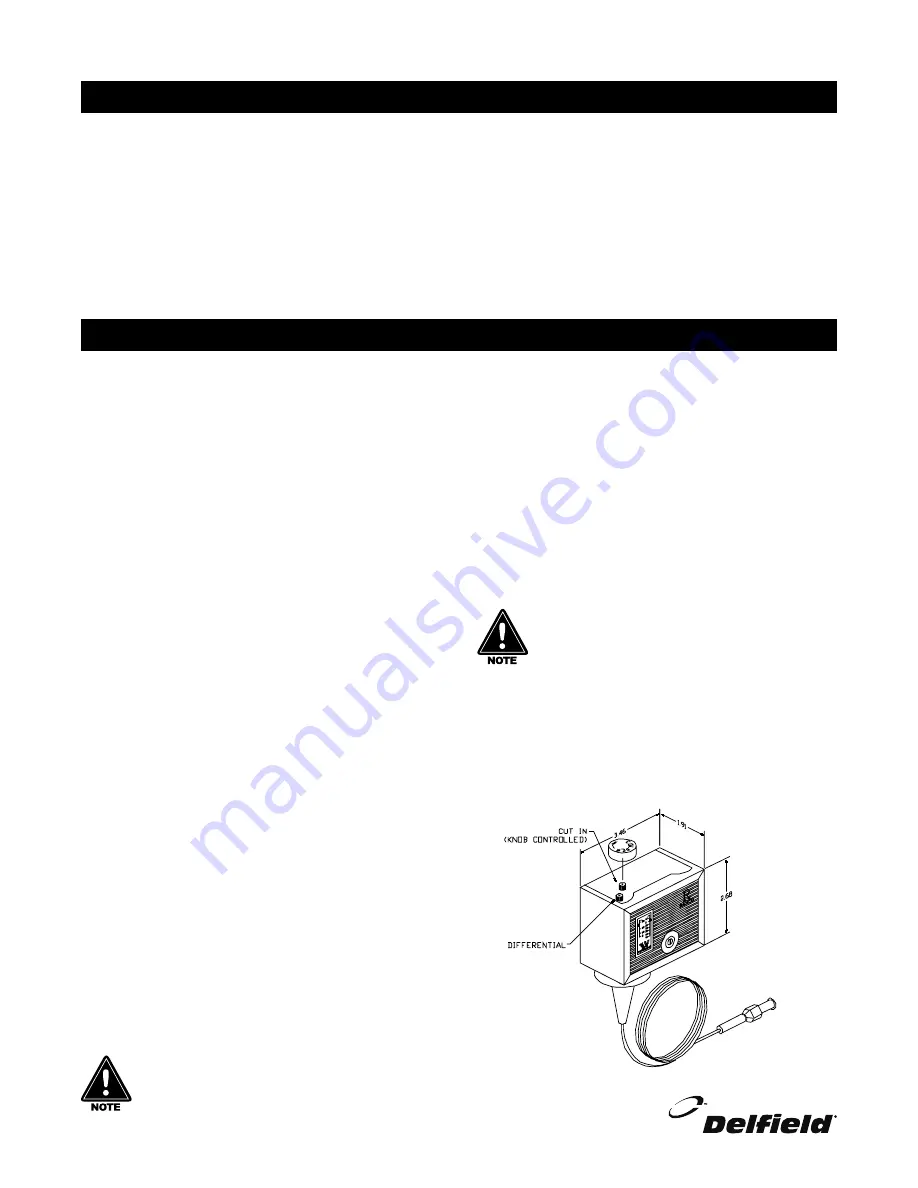

Pressure Control

The temperature on self contained units is controlled by an

adjustable pressure control located in the machine compartment.

An adjustable control has the word COLDER near the knob, with

an arrow to indicate the adjustment direction. These controls

are field adjustable and do not require a service agent. If you

have any questions, feel free to contact the Delfield Service

Department.

In attempting to adjust the pressure control,

you can do damage to your unit by accidentally

adjusting the differential. Please make small

incremental adjustments if a temperature

adjustment is necessary, please contact the

service department at Delfield (800) 733-8829

or your local service agent. Delfield is not

responsible for charges incurred while having the

pressure control adjusted.

Factory recommended low-pressure control settings for

self-contained models are as follows:

Cut in 27# — cut out 11#

EPR valve for syrup rail is set at 65#

These units use a “cold wall” design — heat is

removed from the storage compartments through the

liner walls. Products next to or touching the walls of

the compartment will often be colder than items at

the center of the compartment. For best results, store

items loosely and keep them away from the side walls

as much as possible.

The units are not designed to reduce temperature

quickly. When overloaded with warm items, it may

take several hours to return to normal temperature,

Also, frequent or continuous opening of the lids can

affect the temperature in the storage compartment.

Freezer compartments

Freezer compartments are designed to hold ice cream

at 0°F to 5°F (-18°C to -15°C).