Delitek Waste Compactors – user -/service manual-rev 1.2

DT-200i “Green Ship” Waste Compactor – standard versions 8

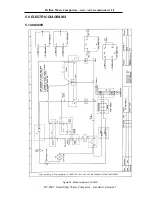

1.5 Final preparation

IMPORTANT INFORMATION!

The hydraulic power pack is delivered with an

airtight temporary filling cap (see fig 7), in order to

avoid oil spill during transport.

To avoid damages or breakdown of the

hydraulic system, it is necessary to replace

the temporary filling cap with the enclosed

standard dipstick, before the compactor is set

into normal operation.

The temporary filling cap is located on top of the

hydraulic oil tank on the el- motor (see figure 7).

Replace the airtight filling cap with the enclosed

standard dipstick that should be found inside the

el-panel.

NOTE:

If the dipstick is missing from the package,

please contact Delitek AS immediately.

See Chapter 8, contact information.

Checking hydraulic oil level:

Check the oil level in the hydraulic oil tank. The oil level should normally be between 55mm and

65mm up on the dipstick in the hydraulic oil tank.

Start the waste compactor and run the piston to its outer (lowest) position and back again.

Check the oil level again and refill if necessary. Oil with specifications similar to Nuto H32/Esso

Univis N32 or equivalent must be used.

Avoid spill of hydraulic oil and also avoid the hydraulic system to be exposed for dust and dirt

during maintenance of the hydraulic system. Use certified protective clothing and equipment

according to working environment law at site. In addition, each country’s legislation regarding

operation of this kind of products and Health, Environment & Safety regulations must be always

followed.

IMPORTANT INFORMATION!

After installation, the compaction cycle should be run approximately 10 times with an empty

container or without container. This is to ensure that there is no air trapped in the hydraulic

system.

Figure 7. Dipstick