21

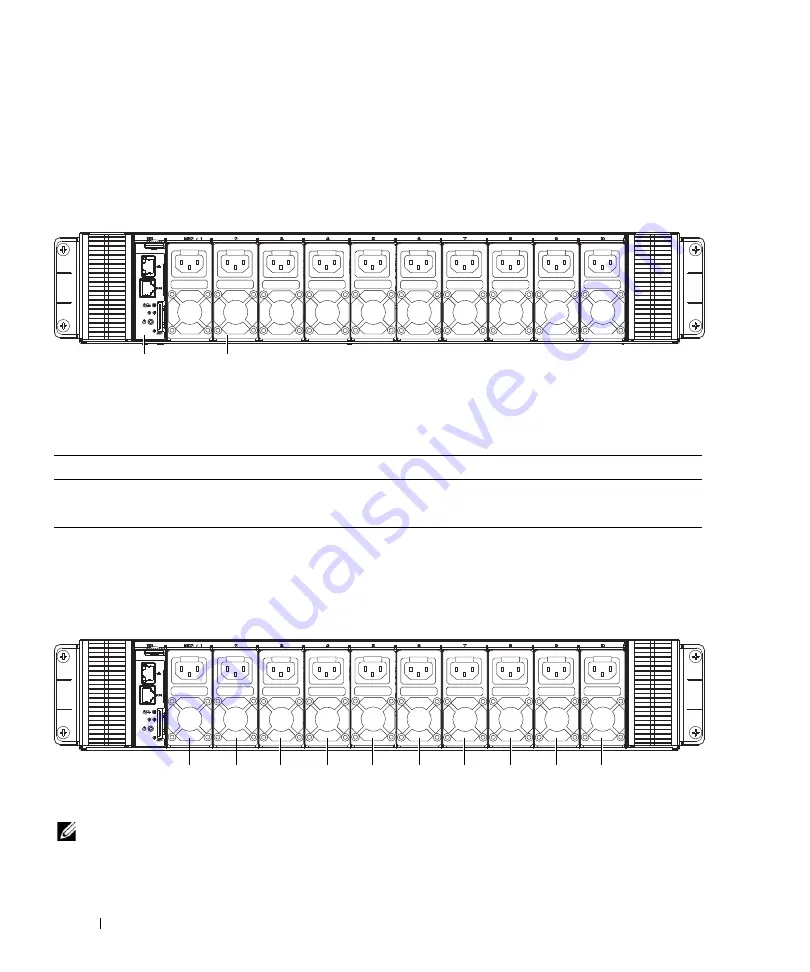

Power bay overview

Power bay unit

The DSS 9000 leverages a power bay which houses up to ten AC power supply units (PSUs) to fully support

the operational requirements of the rack enclosure.

Front view

Figure 27. Power bay 1 MC + 10 PSU model (front view)

Power bay allocation

When populating the PSU bays make sure to first populate bays 1 to 6 then 7 to 10 as required. A minimum

of six power supply units are required to effectively sustain operations.

Figure 28. Power bay allocation

NOTE:

To meet power requirements a minimum of six power supply units must be installed. Make sure to first populate

power bays 1 to 6.

Table 16. Power bay 1 MC + 10 PSU model (front view)

No.

Item

Description

1

MC

One management controller module

2

Power supply unit

Ten hot-swappable power supply unit bays

1

2

1

2

3

4

6

9

7

8

5

10