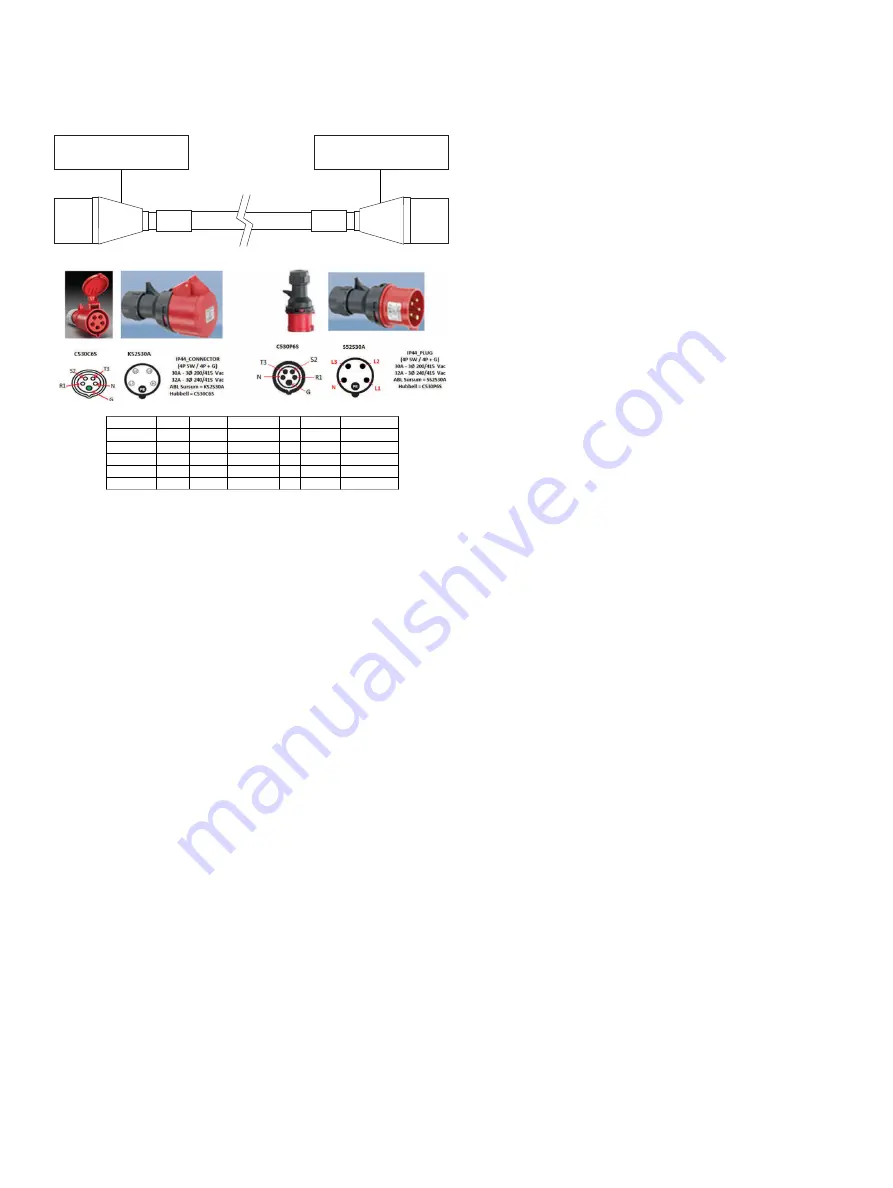

Figure 22 Three-phase, international: E-PCBL3YAG

P1

ABL Sursum - K52S30A or

Hubbell - C530C6S

P2

ABL Sursum - S52S30A or

Hubbell - C530P6S

Wire Color From

Hubbell ABL-Surum

To

Hubbell

ABL-Surum

BRN

P1

R1

L1

P2

R1

L1

BLK

P1

S2

L2

P2

S2

L2

GRY

P1

T3

L3

P2

T3

L3

BLU

P1

N

N

P2

N

N

GRN/YEL

P1

G

PE

P2

G

PE

Power cabling, cords and connectors

64

Dell EMC

™

VMAX3

™

Family Site Planning Guide VMAX 100K, VMAX 200K, and VMAX 400K

Summary of Contents for VMAX3

Page 6: ...Contents 6 Dell EMC VMAX3 Family Site Planning Guide VMAX 100K VMAX 200K and VMAX 400K ...

Page 8: ...Figures 8 Dell EMC VMAX3 Family Site Planning Guide VMAX 100K VMAX 200K and VMAX 400K ...

Page 10: ...Tables 10 Dell EMC VMAX3 Family Site Planning Guide VMAX 100K VMAX 200K and VMAX 400K ...

Page 48: ...Position Bays 48 Dell EMC VMAX3 Family Site Planning Guide VMAX 100K VMAX 200K and VMAX 400K ...