wire. The heat means wasted electricity and possibly

slightly lower voltage.

Use copper wire. Do not allow an electrician to use alu-

minum wire on your new circuit. Aluminum terminals

corrode worse than copper and require greater installa-

tion care. Avoid using extension cords.

Voltage Affects Firing Time

Voltage fluctuation can vary the firing time for a given

pyrometric cone from as little as one half to more than

twice the average time. If the voltage is too low, the kiln

will never reach full temperature. This can be corrected

only by having the utility company adjust the voltage.

PREPARING THE KILN

Kiln Features

Heating Elements

The heating elements in your Delphi kiln are heavy

duty for long life. All high temperature, heavy duty ele-

ments must be handled carefully. They are quite brittle

after being heated to a high temperature and will break if

bent while cold. By heating to a dull red glow with a pro-

pane torch, an element may be bent safely.

Never allow glaze, glass, silica sand, kiln wash, or other

foreign materials to touch the elements since they will de-

stroy the element when the kiln is fired.

Peephole

A peephole, tapered for a wide view without heat loss, is

used for observing the progress of your firing so you can

see when the pyrometric cones bend. Use at least one

large cone on the shelf during

every firing. With venting as

their secondary function,

peepholes allow oxygen to be

drawn into the kiln's chamber

and serve as an escape pas-

sage for smoke and water

vapor.

When looking through the

peepholes, always wear firing safety glasses, which are

available from Delphi. They protect your eyes from the

bright glare of the firing chamber and make it easier to

see the cones at high temperatures.

Prop-R-Vent

Ceramic pieces re-

lease gases and water

vapor during firing.

Venting allows these

gases

to

escape.

Delphi's fall away

Prop-R-Vent is in-

stalled on the switch

box. The prop supports

the lid in an open posi-

tion during the venting period. The Prop-R-Vent vents

the lid in two stages.

To close the lid after venting, lift the lid handle an inch.

The Prop-R-Vent will fall down by itself. Lower the lid

gently; warranty does not cover damage to the kiln or the

ware due to a dropped lid. For lusters and overglazes, en-

gage the Prop-R-Vent in its second position for additional

venting. Do not rush the cooling of your kiln with the

Prop-R-Vent. This can damage your ware.

The Lid Support

Your kiln has the lock-in lid support. Please do not let

unattended children raise the lid. Do not let the lid drop.

It is fragile and must be lowered gently.

Dust-Free Refractory Coating

The dark coating on the lid, the top rim of firebricks,

and in the peepholes reduces dust and hardens the fire-

brick surface for longer life. Though it will lighten after

the first firing, the coating will last for several years.

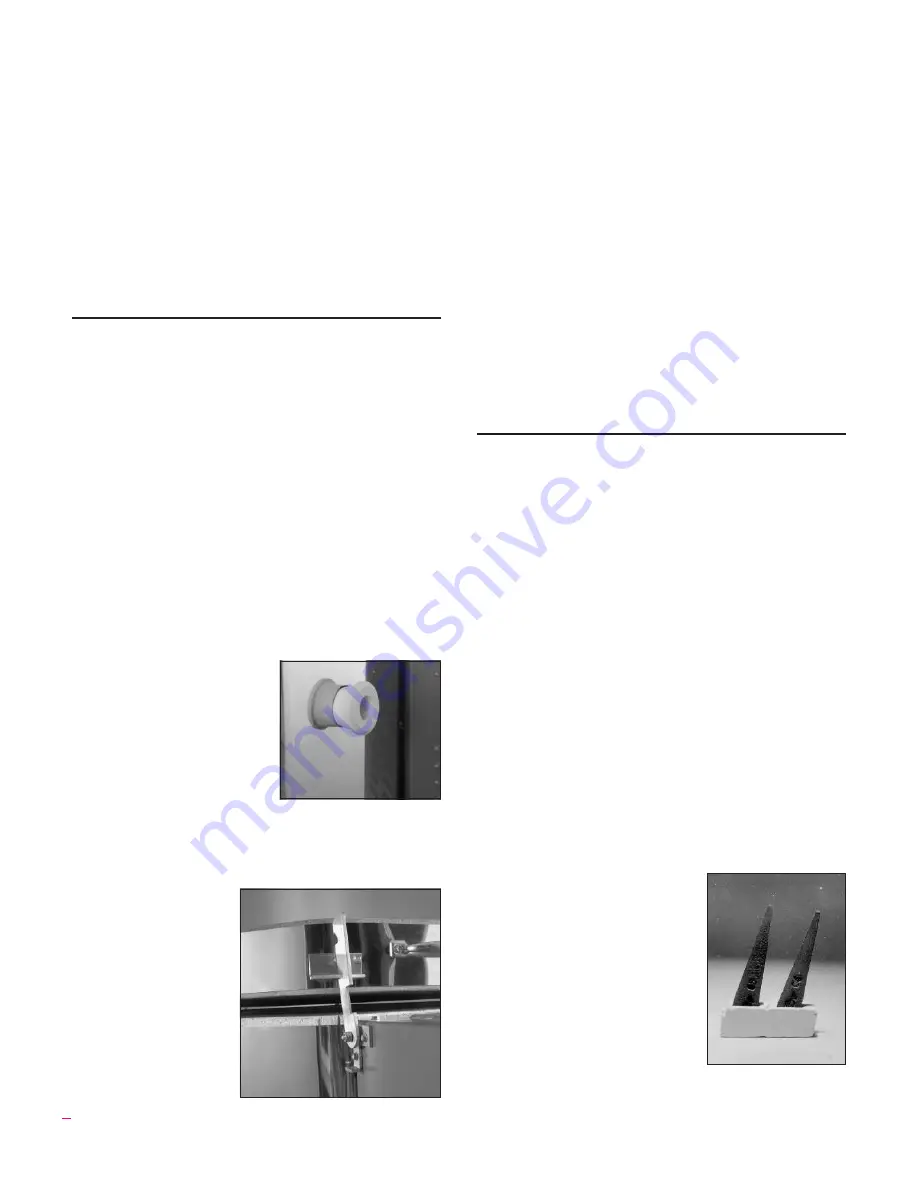

PYROMETRIC CONES

Pyrometric cones are small pyramids of clay and min-

eral oxide that soften and bend when exposed to heat.

They indicate when your ware has fired to maturity.

When consulting your dealer with a glaze problem, you

should have a bent cone from that firing. The cone will

help trouble shoot the problem. The cone lets you com-

pare one firing to the next.

Cone Numbers

Pyrometric cones are numbered from 022 through 01

and 1 through 10. Cone 022 matures at the lowest tem-

perature, and 10 matures at the highest. The number is

stamped on the base of the cone. The cone number for

each material is usually stated on the label by the clay or

glaze manufacturer.

Using Cones

Place the cones on a kiln shelf with the ware. As the

cones heat and bend, they form a glassy material that will

stick to a bare shelf. Therefore, apply kiln wash to the

shelves to prevent sticking. Do not apply kiln wash to the

cones. (See page _ for kiln wash.) The cone slants 8 de-

grees from vertical and bends in the direction of the slant.

They will not bend accurately if

they are slanted at the wrong an-

gle. Place the cone so that it will

not touch nearby ware as it bends.

Large cones come in either

standard or self-supporting.

Standard large cones must be

mounted in a clay or wire plaque

with 2" of the cone exposed above

the cone holder. Or you can

mount large cones in a pat of clay.

The pat of clay should be com-

4

Regular large cones re-

quire a cone plaque.