MAINTENANCE & TROUBLE SHOOTING

EST150

7 / 9

DELTA ELEKTRONIKA B.V.

rev. Jan. 2021

4

MAINTENANCE & TROUBLE

SHOOTING

4.1

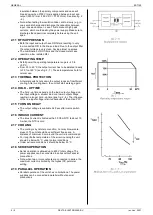

GENERAL

The ES-series power supplies normally need no maintenance

or calibration. Only care must be taken that the cooling of the

unit is not obstructed.

4.2

NO OUTPUT (normal operation)

Remove load from output.

Check position of prog. switches at the rear panel, they

should be on MANUAL.

Switch on unit.

Turn all the CV and CC potentiometers a few turns clock-

wise. A voltage should be present on the output.

4.3

NO LEDS on.

Overheating can be the cause, cooling down will reset the

thermal protection.

Check input power.

Check fuses inside unit.

4.4

NO equal voltages in Tracking Mode

One or both of the tracking outputs are in CC mode (CC LED

on).

Turn the CC potentiometers fully clockwise.

Reduce the load.

3.3.2

HUMIDITY

During normal operation humidity will not harm the power

supply, provided the air is not aggressive. The heat normally

produced in the power supply will keep it dry.

Condensation. Avoid condensation inside the power supply,

break-down could be the result. Condensation can occur

during a period the power supply is switched off (or operating

at no load) and the ambient temperature is increasing .

Always allow the power supply to dry before switching it on

again.

3.3.3

GALVANIC INDUSTRY

For using the power supplies in the galvanic industry it is

strongly recommended to take precautions against an

aggressive environment.

An aggressive environment with acid, salt, etc. can harm the

electronic components. Sometimes even the copper traces of

the pc-boards dissolve.

To avoid problems the power supplies should be mounted in

a relative clean room, or mounted in a cabinet receiving clean

air with over pressure. Or a cabinet with a heat exchanger.