INSTALLATION

SM6000

13 / 21

DELTA ELEKTRONIKA B.V.

rev. Nov. 2020

4

INSTALLATION

Warning!

carefully read the chapter "Safety Instructions" in

this manual before connecting or operating the unit!

4.1

HUMIDITY & CONDENSATION

During normal operation, humidity will not harm the power

supply, provided the air is not aggressive. The heat normally

produced in the power supply will keep it dry.

Avoid condensation inside the power supply, to prevent

break-down. Condensation can occur during a period the

power supply has been switched off (or operating at no load)

and the ambient temperature is increasing. Always allow the

power supply to dry before switching it on again.

4.2

TEMPERATURE & COOLING

The storage temperature range is

–40 to +85 °C.

The operating temperature range at full load is

–20 to +50 °C.

This temperature range only holds when the air-intakes and

air-outlets are unobstructed and the temperature of the air-

intake is not higher than +50 °C.

When the power supply is mounted in a cabinet, please note

that the temperature of the air-intake should be kept low and

avoid a short circuit in the airflow i.e. the hot air leaving the

air-outlets entering the air-intakes again.

Please note: a lower temperature extends the lifetime of the

power supply.

4.3

19" RACK MOUNTING

On both sides in the rack, mount a proper support slide that

can hold the weight of the unit. It is advised to use a separate

slide for each unit.

After placing the unit on the slide, add all 4 screws to mount

the front panel of the power supply to the vertical rack posts.

Use proper screws intended for keeping equipment of this

weight in position.

Assuming the rack is deliberately designed for the weight,

stacking of the units is allowed without limitations. See

previous paragraph for cooling instructions.

4.4

OPERATING THE UNIT FOR THE FIRST TIME

Check there is no condensation on the unit. If there is, allow

some time to dry.

Check there is a link b and S+ and between

– and

S

– on the SENSE BLOCK (on rear panel).

Check there is a link between pins of the Interlock (CON A).

Set the CV and CC potentiometers to minimum (fully anti

clockwise). For units with Option P220, this is not needed.

These units are set to start at 0 V - 0 A when operated for the

first time.

For the mains power, connect a cable of 4-wires of 2.5mm

2

.

Use a torque of 0.6Nm to fasten the screws on the AC input

connector.

For the DC output power, see table 4 - 1 for cable diameters

and mounting torque.

For

high DC current

make sure to use low resistive

connections between the power supply and the load:

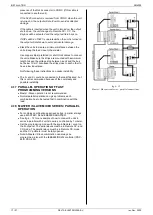

- Mount the cable lugs directly on the DC output strips

followed by a washer, split washer and a nut (see fig. 4 - 1).

Always in this order!

- Never place washers between the lugs and the strips

because this can result in excessive heat!

- Only use nuts and washers supplied with the unit.

Switch on unit.

Disable the Keylock function, see next paragraph.

Check the unit is not in Remote CV or Remote CC (LED’s for

this function should be off). Press the REMOTE/LOCAL

button until both LED’s are off.

Turn on DC output by pressing the OUTPUT ON/OFF button.

Turn both the CV and CC potentiometer a few turns

clockwise.

A voltage should now be present on the output.

By pressing the DISPLAY CV/CC SETTING button the meters

fig 4 - 1

Low resistive cable connection by mounting the

cables directly on the DC output strips.

Unit

DC Output

cable [mm

2

]

Bolts

Torque

[Nm]

SM15-400

150

M12

80

SM30-200

70

M10

40

SM45-140

35

M10

40

SM60-100

35

M10

40

SM70-90

25

M10

40

SM120-50

10

M8

20

SM300-20

4

M8

20

SM600-10

2.5

M8

20

table 4 -1

Recommended cable diameters and mounting torque.