INSTALLATION

SM3300

15 / 30

DELTA ELEKTRONIKA B.V.

rev. Jan. 2022

The operational isolation of SM18-220, SM66-AR-110 and

SM100-AR-75 allows a total series voltage of 1000V.

The operational isolation of SM330-AR-22 and SM660-AR-11

allows a total series voltage of respectively 1330V and 1400V.

Warning!

The minus power output of the unit is allowed to be

maximum 1000VDC higher or lower than the Protective Earth,

regardless of the higher allowed series voltage!

For more details, see Safety Instructions in chapter 2.

5.9

PARALLEL OPERATION

The power supplies can be connected in parallel without

special precautions. Paralleling of the units has no limitations.

Normal parallel operation of units High Speed Programming

units can give problems. Each combination has to be tested

first, in combination with the load!

5.10

OPTIONAL MASTER / SLAVE CONTROL

For easy series or parallel operation the Master / Slave

interface is advised.

Master / Slave parallel operation of High Speed Programming

units is not recommended.

See chapter 7 for more information about the M/S interface.

5.11

OPTIONAL POWER SINK

5.11.1

SETTING UP THE POWER SINK

Settings for disabling/enabling can be made via the web

interface, see chapter 7.

5.11.2

POWER SINK OVERLOAD (PSOL)

If the maximum sink power has been reached, the Power Sink

will go in overload and the sink current will be limited. In this

situation the Sink cannot absorb more power and the output

voltage of the supply will rise.

On the front panel the PSOL icon will be blinking and the

status output 'PSOL' will be high.

5.11.3

THERMAL OVERLOAD (OT)

If the Power Sink runs hot, the fan starts blowing to cool it

down. Once the situation of thermal overload has been

reached, the Power Sink and the output shut down completely

until the internal heat sink has cooled down again. In this

OverTemp situation the OT-status will be high.

5.11.4

SERIES OPERATION

For series operation in combination with Power Sink option,

all units must have a Power Sink built inside otherwise no

power can be absorbed.

When using Master/Slave mixed parallel/series operation,

automatically the Power Sink will be disabled for both Master

and all Slaves.

5.11.5

PARALLEL OPERATION

For parallel operation in combination with Power Sink option,

only one unit can have a Power Sink. The output voltage of

this unit must be set 0.5% higher than the other units (to avoid

unintended sinking of Slave power).

When using Master/Slave parallel operation, always set the

unit with the power sink as master. The firmware will

automatically reduce the voltage setting with of each Slave

with 0.5% to avoid unintended sinking, and disable the Power

Sink in each Slave.

When using Master/Slave mixed parallel/series operation,

automatically the Power Sink will be disabled for both Master

and all Slaves.

5.12

SPECIAL APPLICATIONS

5.12.1

PULSATING LOAD

To avoid overheating the output capacitors, the AC compo-

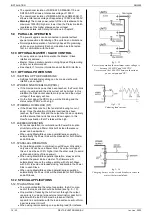

nent of the load current should be limited (see fig. 5 - 13).

One method of reducing the AC current through the output

capacitor is by using a large external electrolytic capacitor in

parallel with the load. Care must be taken so that the

capacitor in combination with the lead inductance will not form

a series resonant circuit!

When using remote sensing on a pulsating load (for instance

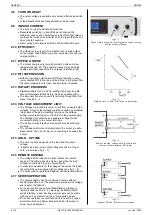

fig 5 - 12

For series operation the maximum series voltage is

between 1000VDC and 1400VDC.

Never exceed the 1000 VDC between the minus

power outputs and PE!

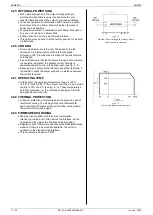

fig 5 – 13

Pulsating load current.

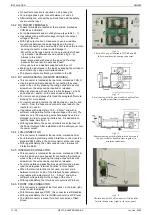

fig 5 - 14

Charging battery with a circuit breaker in series to

protect the internal diode.