MAINTENANCE & CALIBRATION

SM3300

28 / 30

DELTA ELEKTRONIKA B.V.

rev. Jan. 2022

fig 9 -1

The fan is located at the left side and blows through

the tunnel.

9

MAINTENANCE & CALIBRATION

9.1

GENERAL

The SM-series power supplies do not need any maintenance

or calibration. However, care must be taken that the cooling

unit is not obstructed.

9.2

COOLING FAN

The internal construction of the power supply is such that no

dust will reach the sensitive control circuitry, only the heat

sink in a tunnel will be cooled by forced air (see fig. 9 - 1)

The built up of dust on the impeller of the fan and the heat

sink fins depends on the environment. It is advised to inspect

the fans and heat sinks regularly.

Since the used fan type has an over-capacity, dust will not

present a problem very quickly.

The thermal protection will shutdown the output in case of

overheating, so no damage will be done to the power supply.

9.3

GALVANIC INDUSTRY

For using the power supplies in the galvanic industry it is

strongly recommended to take precautions against an

aggressive environment.

An aggressive environment with acid, salt, etc. can harm the

electronic components. Sometimes even the copper tracks on

the printed circuit boards dissolve.

To avoid problems, the power supplies should be mounted in

a relatively clean room, in a cabinet receiving clean air with

over pressure, or a cabinet with a heat exchanger.

9.4

CALIBRATION

The power supplies are factory calibrated and normally need

no further calibration.

After installation of a new or different interface, no calibration

is needed.

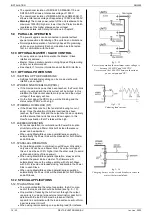

Only in special situations, for example after repairing a unit,

calibration can be necessary.

The SM3300 units can only be calibrated by software.

Inside the unit, there are no positions with calibration

components such as trimmers or CR-resistors.

The software calibration is performed by connecting the unit

to a TCP/IP network using the LAN connector at the rear

panel.

Download the programming manual for Ethernet & Sequencer

via the web interface or via