12

Fig. 17

Fig. 16

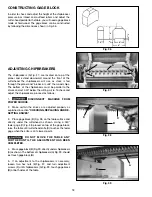

Fig. 19

Fig. 20

Fig. 18

FEED ROLLER SPEEDS

Your planer is equipped with feed roller speeds of 20

and 30 feet per minute depending on belt placement

on the pulleys. As a rule, a faster feed rate is used for

general planing operations, while a slower feed rate

(because it provides more cuts per inch of stock) gives

a finer and smoother finish to the workpiece.

1.

To engage the feed rollers, simultaneously push

button (A) Fig. 16, and pull downward on handle (B).

2.

To disengage the feed rollers, simultaneously push

button (A) Fig. 17, and move handle (B) to the raised

position, as shown.

3.

To change feed roller speeds, disengage the feed

rollers as explained in

STEP 2

.

4.

DISCONNECT MACHINE FROM

POWER SOURCE

.

5.

Open two doors (C) and (D) Fig. 18, located on the

left side of the machine.

6.

Reposition drive belt (E) Fig. 19, on pulleys (F) and

(G). When belt (E) Fig. 19, is on the smallest step of

motor pulley (G) and the largest step of the gear box

pulley (F), the feed roller speed will be 20 feet per

minute. When belt (E) Fig. 19, is on the largest step of

the motor pulley (G) and the smallest step of gear box

pulley (F), the feed roller speed will be 30 feet per

minute. A feed rate adjustment chart is located on the

back of panel (C) Fig. 20, for quick reference.

A

B

A

B

C

D

F

E

G

C