18

Fig. 36

Fig. 37

Fig. 38

Fig. 39

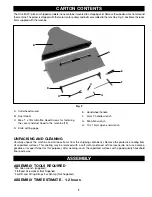

CONSTRUCTING GAGE BLOCK

In order to check and adjust the height of the chipbreaker,

pressure bar, infeed and outfeed rollers and adjust the

cutter-head parallel to the table, you will need a gage block

made of hard wood. The gage block can be constructed

by following the dimensions shown in Fig. 36.

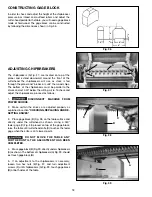

ADJUSTING CHIPBREAKERS

The chipbreakers (A) Fig. 37, are located on top of the

planer and extend downward around the front of the

cutterhead. The chipbreakers will rise as stock is fed

through the planer and “breaks or curls” the wood chips.

The bottom of the chipbreakers must be parallel to the

knives and set .040" below the cutting circle. To check and

adjust the chipbreakers, proceed as follows:

1.

DISCONNECT MACHINE FROM

POWER SOURCE.

2.

Make certain the knives are adjusted properly as

explained in section

“CHECKING, REPLACING AND RE-

SETTING KNIVES.”

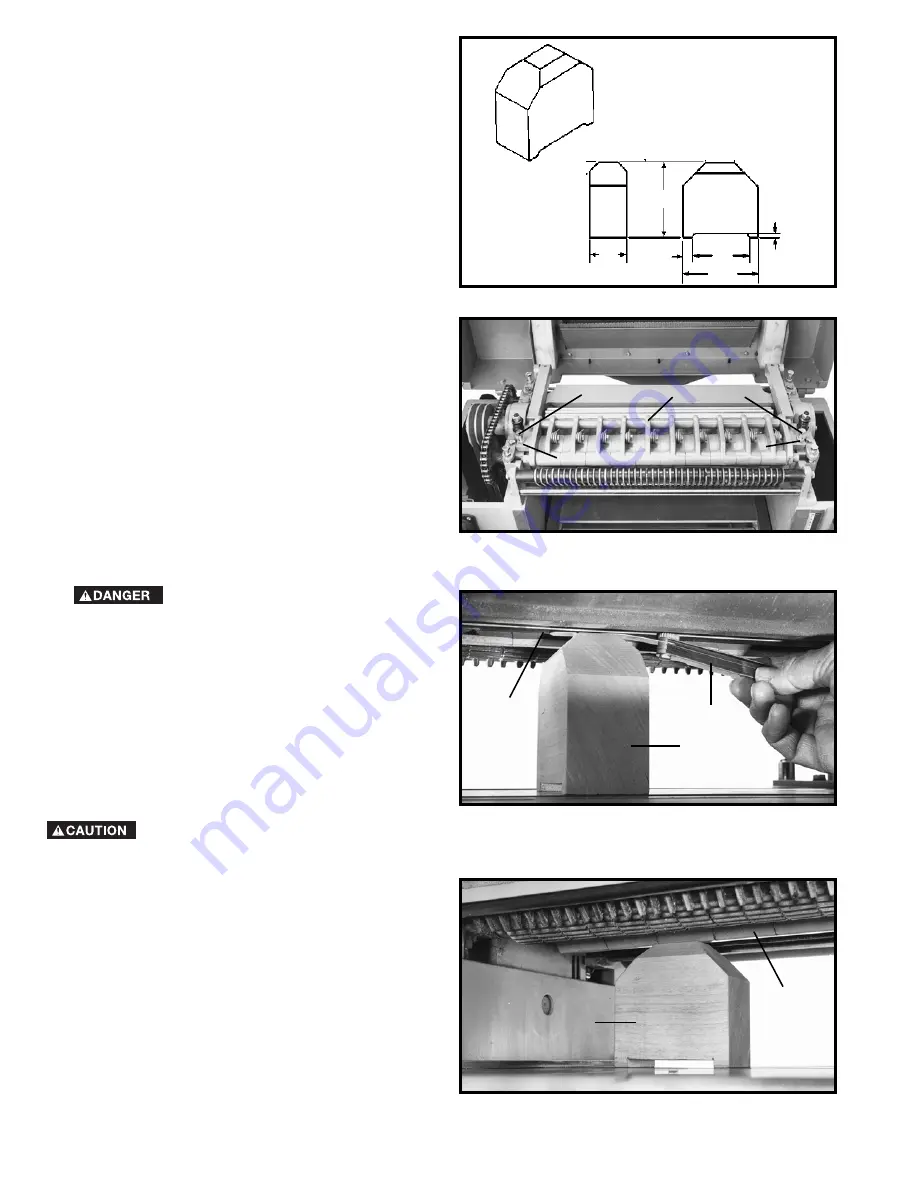

3.

Place gage block (B) Fig. 38, on the table surface and

directly under the cutterhead as shown. Using a .040"

feeler gage (C) Fig. 38, placed on top of the gage block,

raise the table until cutterhead knife (D) touches the feeler

gage when the knife is at its lowest point.

D O N O T M O V E T H E TA B L E A N Y

FURTHER UNTIL THE ADJUSTMENT HAS BEEN

COMPLETED

.

4.

Move gage block (B) Fig. 39, directly under chipbreakers

(A) as shown. The bottom of chipbreakers (A) Fig. 39, should

just touch gage block (B).

5.

If an adjustment to the chipbreakers is necessary,

loosen two hex nuts (E) Fig. 37, and turn adjustment

screws (F) until chipbreakers (A) Fig. 39, touch gage block

(B) at both sides of the table.

2"

1/

2

"

1

/ 4

"

4"

3"

4"

F

E

F

E

A

C

B

D

A

B