20

4.

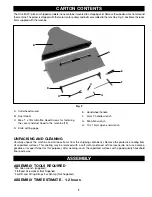

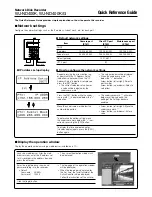

Place gage block (A) Fig. 44, under outfeed roller (D).

The bottom of roller (D) should just touch gage block (A).

5.

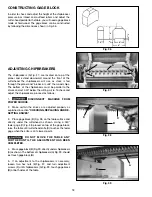

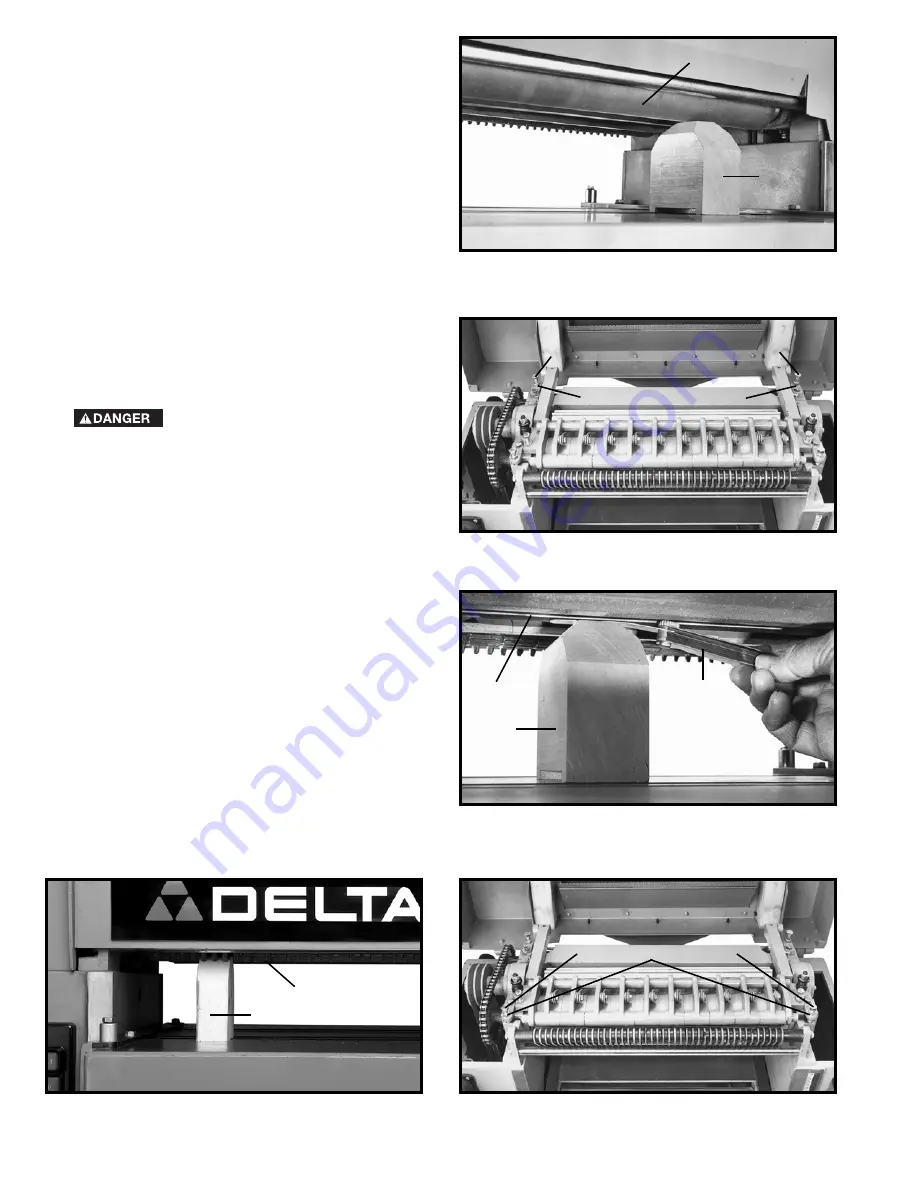

If an adjustment is necessary, loosen locknut (E)

Fig. 45, and turn adjustment screw (F) until the outfeed

roller just touches the top of gage block (A) Fig. 44.

6.

Repeat the adjustment on the opposite end of the

outfeed roller in the same manner.

7.

Tighten locknuts (E) Fig. 45 after adjustments are com-

pleted.

Fig. 44

Fig. 45

Fig. 46

Fig. 48

Fig. 47

ADJUSTING INFEED ROLLER

The infeed roller feeds the stock into the planer while the

stock is being surfaced. The infeed roller must be

positioned uniformly across the planer and .040" below

the cutting circle to feed the stock without slipping. To

check the setting of the infeed roller, proceed as follows:

1.

DISCONNECT MACHINE FROM

POWER SOURCE.

2.

Make certain the knives are adjusted properly as

explained in section

“CHECKING, ADJUSTING AND

REPLACING KNIVES.”

3.

Place gage block (A) Fig. 46, on the table, directly

under the cutterhead (B). Using a .040" feeler gage (C)

placed on top of the gage block (A), raise the table until

the cutterhead knife just touches feeler gage (A) when

the knife is at its lowest point.

NOTE:

Do not move the

table any further until the adjustment is complete.

4.

Place gage block (A) Fig. 47, under infeed roller (D).

The bottom of roller (D) should just touch gage block (A).

5.

If an adjustment is necessary, loosen locknut (E)

Fig. 48, and turn adjustment screw (F) until the infeed

roller just touches the top of gage block (A).

6.

Repeat the adjustment on the opposite end of the

infeed roller in the same manner.

7.

Tighten locknuts (E) Fig. 48, after adjustments are

completed.

D

A

F

E

F

E

C

B

A

D

A

F

F

E