11

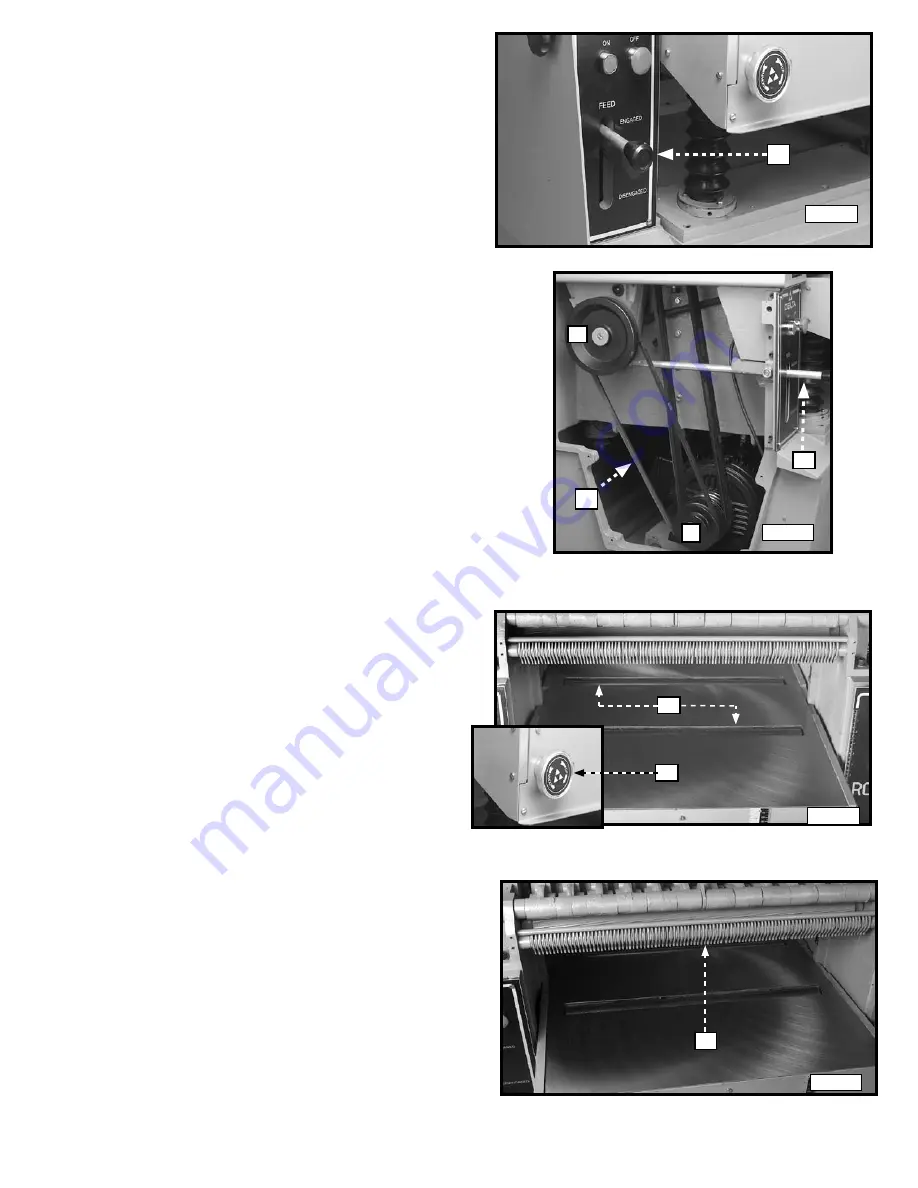

Your planer is supplied with two table rollers (A) Fig. 14

that reduce friction by rolling as the stock feeds through

the planer. Because different types of wood behave dif-

ferently, exact dimensions on the proper height setting

of the table rollers are not available. As a general rule,

however, when planing rough stock, set the table rollers

HIGH. When planing smooth stock, set the table rollers

LOW.

To raise the table rollers (A) Fig. 14, turn the adjustment

knob (B) inset clockwise. To lower, turn the adjustment

knob (B) counter-clockwise.

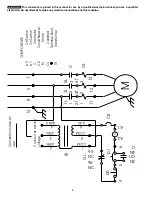

Your planer has feed roll speeds of 25 and 46 feet

per minute. When the feed roll lever (A) is in the "up"

position (Fig. 12), the feed rolls are engaged and the

planer will feed. When the lever (A) is in the "down"

position, the feed rolls are disengaged and the planer

will not feed.

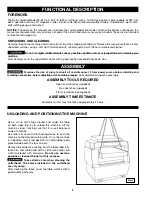

To change feed roll speeds, disengage the feed roll

lever (A) Fig. 13 by placing it in the down position.

Open the left side door of the machine. When the belt

(C) is on the smallest step of the motor pulley (D) and

the largest step of the gearbox pulley (E), the feed roll

speed is 25 feet per minute. When the belt (C) is on the

largest step of the motor pulley (D) and the smallest

step of the gearbox pulley (E), the feed roll speed is 46

feet per minute.

A

E

C

D

A

A

A

Fig. 12

FEED ROLL SPEED CONTROLS

Fig. 13

Fig. 14

Fig. 15

B

TABLE ROLLERS

Anti-kickback fingers (A) Fig. 15 on your planer

prevent kickback. These fingers operate by gravity.

Inspect them occasionally to make sure that they are

free of gum and pitch so that they can move indepen-

dently and operate correctly.

ANTI-kICkBACk FINgERS

Summary of Contents for 22-610

Page 63: ...63 NOTES NOTAS ...