15

Your planer has two feed roll speeds - 16 and 30 feet per minute (8 cm and 15 cm per second). The slower feed rate

provides more cuts per inch and a finer, smoother finish. For efficiency, operate the machine at the faster feed rate for

general planing and switch to the slower feed rate for the final finish. When planing wide stock - wider than 8" (203 mm)

- particularly in hard wood, the slower feed speed is better because of less strain on the motor and a better finish.

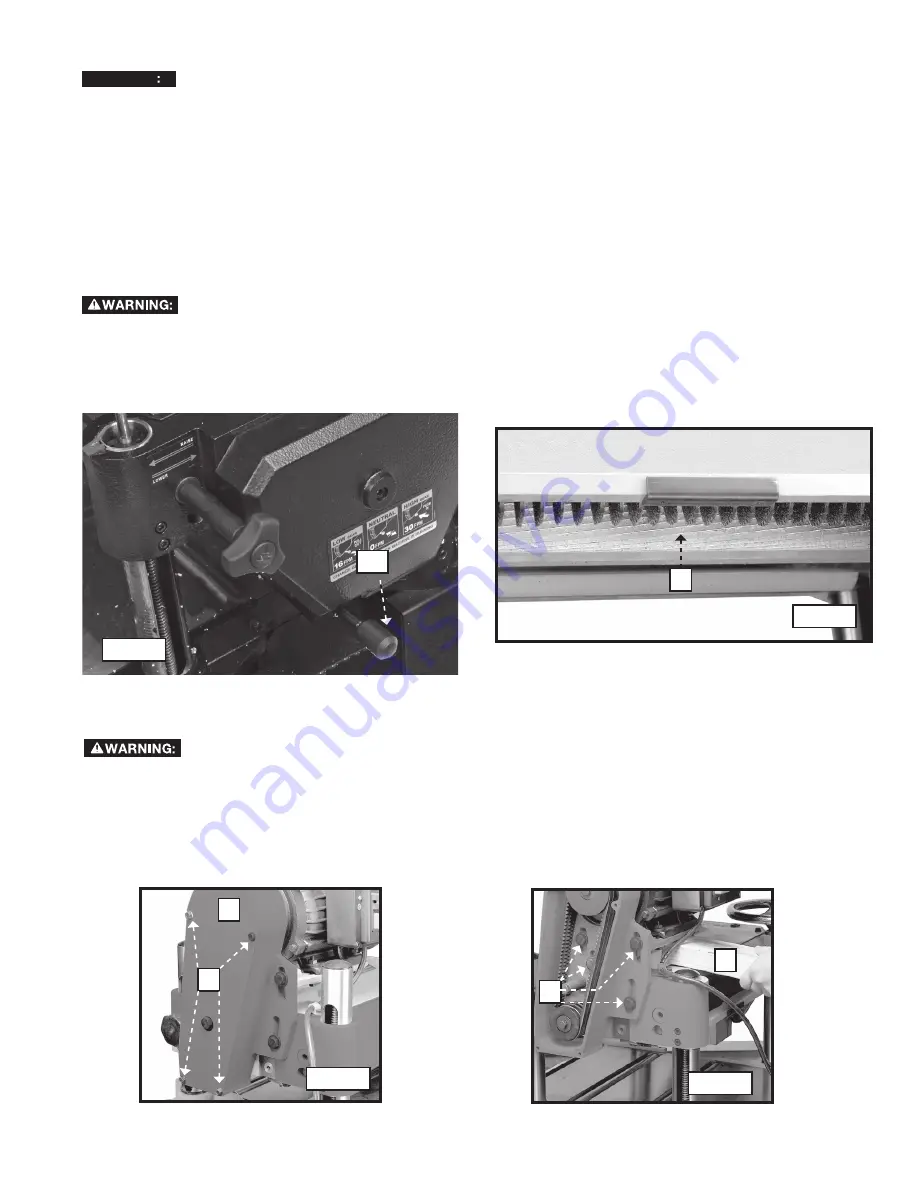

With the shifter knob (S) Fig. 35 pushed all the way in, the feed speed is 30 fpm (15 cm/s). With it is pulled all the way

out, the feed speed is 16 fpm (8 cm/s). When the knob is in the center (neutral) position, the machine will not feed.

A series of anti-kickback fingers (A) Fig. 36 are provided on the infeed end of the planer. These anti-kickback fingers

operate by gravity and no adjustment is required. However, you should inspect them occasionally to confirm that they

are free of gum and pitch and that they move and operate correctly.

1. Take out the four bolts (A) Fig. 37 to remove the belt and pulley guard cover (B).

2. Place a 2 x 4 (D) Fig. 38 between the motor plate and the top of the head casting.

3. Loosen the four screws (C) Fig. 38. Leverage the motor plate upward until the belt deflects approximately 1/4"

(6.4 mm) in the center span with light finger pressure.

4. Tighten the three screws (C) Fig. 38 and replace the belt and pulley guard cover (B) Fig. 37.

HOW TO CONTROL THE FEED SPEED

NOTICE

AVIS

AVISO

fr

sp

Change speeds only while the motor is running.

DO NOT

change speeds while planing.

USE OF THE ANTI-KICKBACK FINGERS

When inspecting and cleaning the anti-kickback fingers, disconnect the machine from the power

source.

A

Fig. 36

HOW TO ADJUST BELT TENSION

Disconnect the machine from the power source.

Fig. 37

Fig. 38

A

C

D

B

S

Fig. 35