21

IM POR TANT:

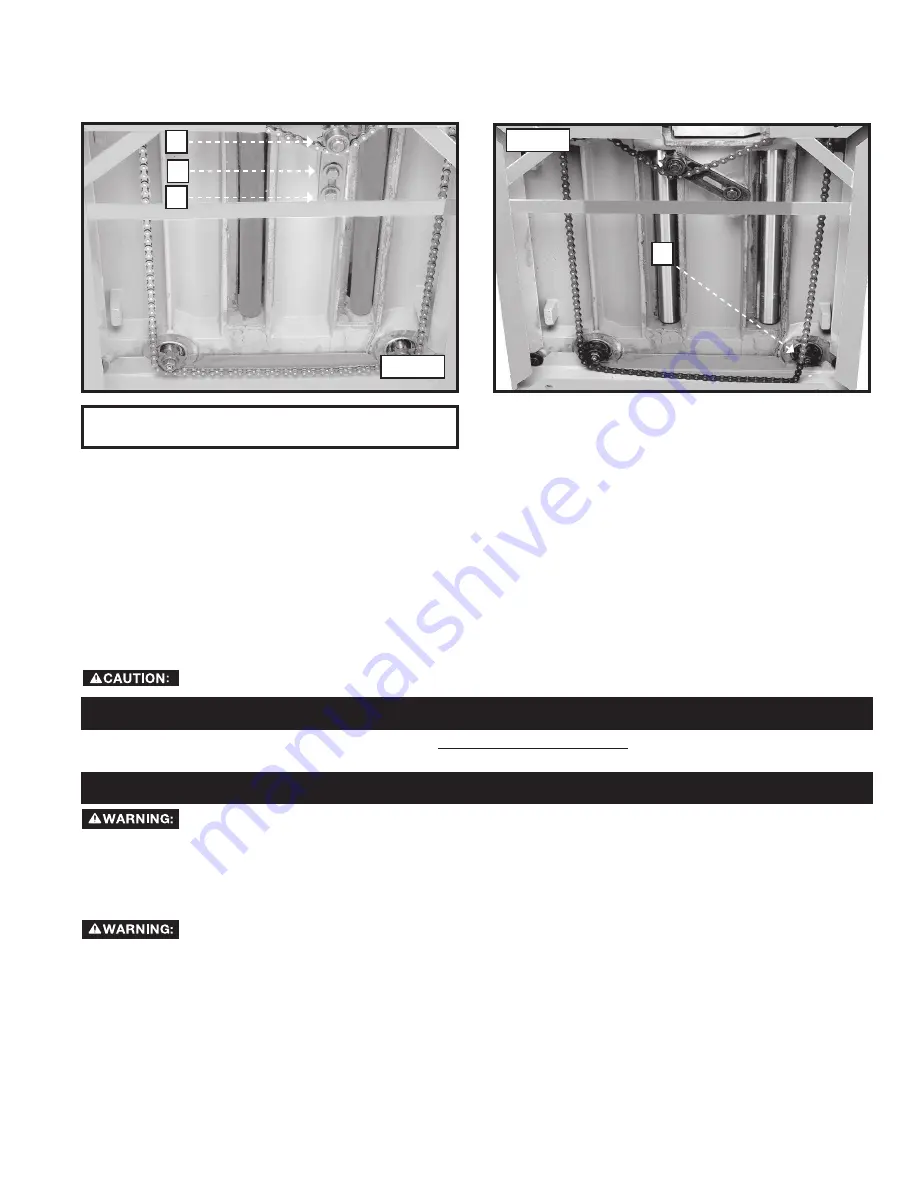

This adjustment is sensitive, and you probably won't have to turn the sprocket more than two teeth.

Turning the sprocket (F) clockwise will decrease the distance be tween the table and headcasting. Counterclockwise

turning will increase the distance.

6. Replace the chain. Do not disturb the position of the sprockets. Replace the idler sprocket assembly (E) Fig. 60.

When using your machine, follow these few steps to achieve the best results.

1. True One Face – Feed one face of the board over a jointer, making thin cuts with each pass, until the entire surface

is flat.

2. Plane to Thickness

– Place the side you just surfaced in

STEP 1

face down and feed the board through the planer,

plane until this side is flat. Then plane both sides of the board until you are satisfied with the thickness, making

thin cuts, alternating sides with each pass. If, during the planing operation, you notice the board twisting, warping

or bowing, repeat

STEP 1

and true one face.

3. When planing long stock, provide table extensions to support the infeed and outfeed end of the workpiece.

4. Always engage the cutterhead lock before planing. Plane with the grain only, and keep table clean. Occasionally, wax

the table surface to reduce friction.

5. Cross-cut the workpiece to its final length.

Feed the wood through the planer at different places on the table to help eliminate uneven wear of the knives.

MACHINE USE

Fig. 60

Fig. 61

E

D

C

F

TROUBLESHOOTING

For assistance with your machine, visit our website at

www.deltaportercable.com

for a list of service centers or call the

DELTA Machinery help line at 1-800-223-7278 (In Canada call 1-800-463-3582).

MAINTENANCE

To reduce the risk of injury, turn unit off and disconnect it from power source before installing and

removing accessories, before adjusting or when making repairs.

An accidental start-up can cause injury.

KEEP MACHINE CLEAN

Periodically blow out all air passages with dry compressed air. All plastic parts should be cleaned with a soft damp cloth.

NEVER use solvents to clean plastic parts. They could possibly dissolve or otherwise damage the material.

Wear certified safety equipment for eye, hearing and respiratory protection while using compressed air

FAILURE TO START

Should your machine fail to start, check to make sure the prongs on the cord plug are making good contact in the outlet.

Also, check for blown fuses or open circuit breakers in the line.

LUBRICATION AND RUST PROTECTION

Apply household floor paste wax to the machine table, extension table or other work surface weekly. Or use a

commercially available protective product designed for this purpose. Follow the manufacturer’s instructions for use and

safety.

To clean cast iron tables of rust, you will need the following materials: a medium sized scouring pad, a can of spray

lubricant and a can of degreaser. Apply the spray lubricant and polish the table surface with the scouring pad. degrease

the table, then apply the protective product as described above.