10

Fig. 26

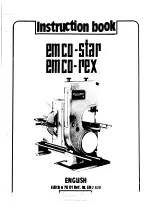

Fig. 23

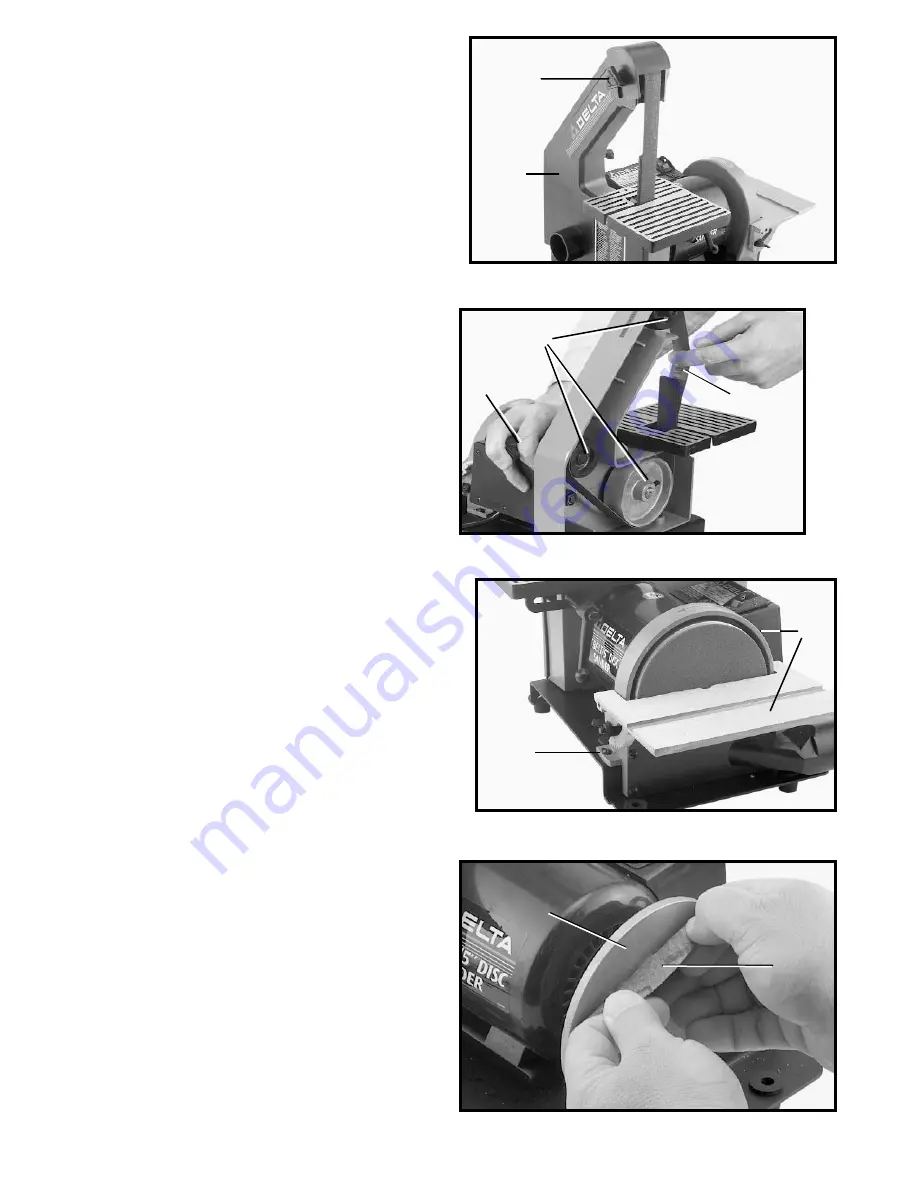

Fig. 24

Fig. 25

CHANGING ABRASIVE BELT

1.

DISCONNECT MACHINE FROM POWER SOURCE.

2.

Remove lock knob (A) Fig. 23, and remove side

cover (B).

3.

Depress tracking knob (C) Fig. 24, to release belt

tension and remove belt (D) from the three wheels (E), as

shown.

4.

Install new belt and replace side cover. Check belt

tracking by referring to the section

“TRACKING THE

BELT”.

CHANGING SANDING DISC

1.

DISCONNECT MACHINE FROM POWER SOURCE.

2

Remove the two screws, one of which is shown (A)

Fig. 25, and and remove the sanding disc guard and

table (B).

A

B

C

D

E

A

B

3.

Remove the used sanding disc (C) Fig. 26, from disc

plate (D).

4.

Make sure disc plate (D) Fig. 26, is clean.

5.

Peel half of the backing from the new sanding disc.

Press this half firmly in place. Remove the other half of

the backing and press in place.

6.

Replace sanding disc guard and table, that was

removed in

step 2.

C

D