7

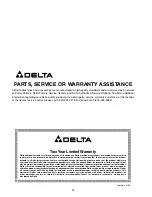

ATTACHING ABRASIVE TO

SANDING DISC

1.

DISCONNECT MACHINE FROM POWER SOURCE.

2. Remove one-half of the abrasive backing (A) Fig. 7,

to expose the adhesive.

3. Attach the lower section of the abrasive to the

sanding disc (B), making sure that the abrasive edges

fit the sanding disc edges exactly.

4. Remove the other half of the abrasive backing.

5. Attach the upper edge of the abrasive backing to the

sanding disc. Press the entire abrasive to be certain that

it is attached solidly to the sanding disc.

Fig. 7

A

B

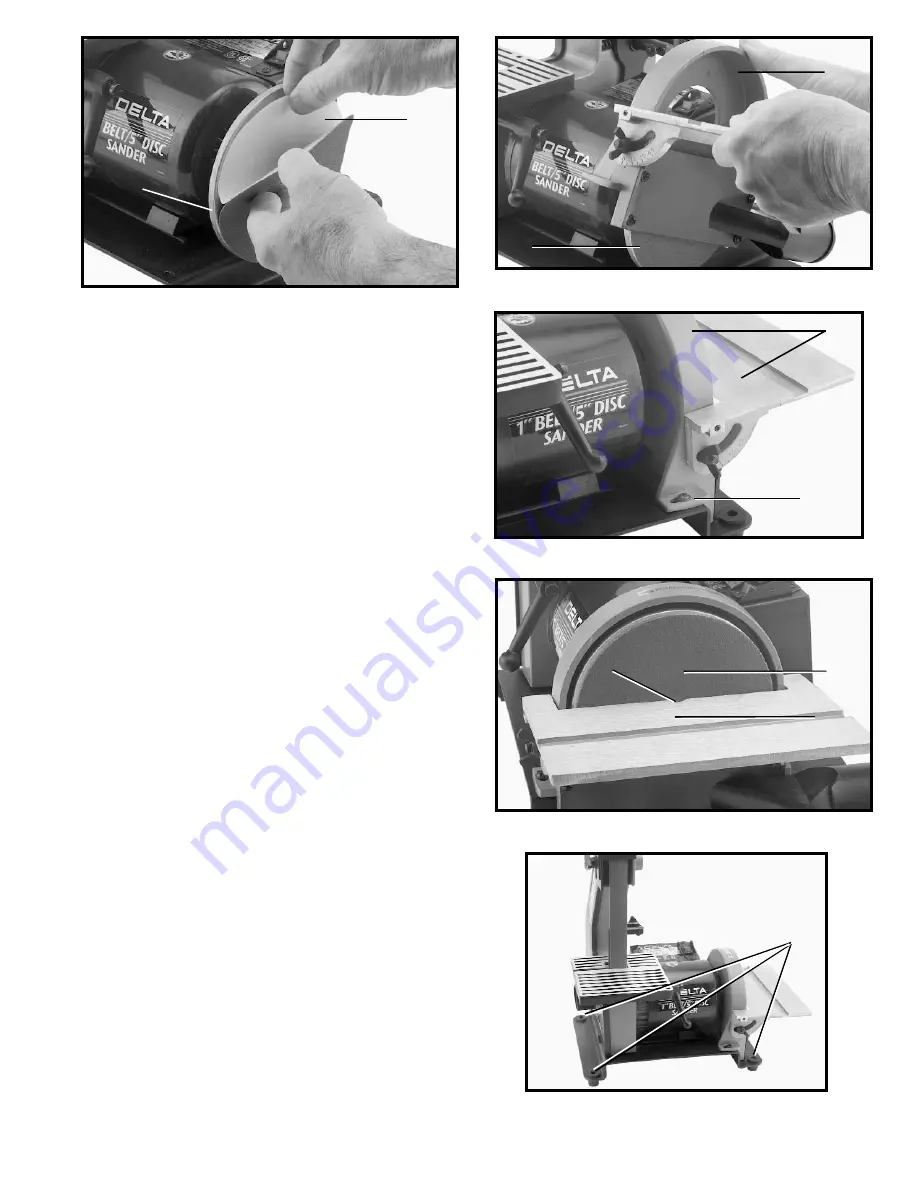

ATTACHING SANDING

DISC GUARD AND TABLE

1.

DISCONNECT MACHINE FROM POWER SOURCE.

2.

Position the sanding disc guard with table (A) Fig. 8,

over sanding disc (B).

3.

Fasten the sanding disc guard with table (A) Fig. 9,

to base using the two 3/8" long screws, one of which is

shown at (B).

4.

WARNING: To avoid trapping the workpiece or

your fingers between the table (A) and the sanding

disc (B), adjust the table so that it is a maximum 1/16"

from disc, between the work table and the disc (see

the section “DISC TABLE ADJUSTMENTS”)

.

Fig. 8

A

B

Fig. 9

A

B

Fig. 10

A

B

C

Fig. 11

A

FASTENING SANDER TO

SUPPORTING SURFACE

IMPORTANT:

If the machine has a tendency to tip over

or to walk on the supporting surface, the machine must

be secured. Use the four holes, three of which are shown

at (A) fig. 11 to attach the machine to the supporting

surface.