12

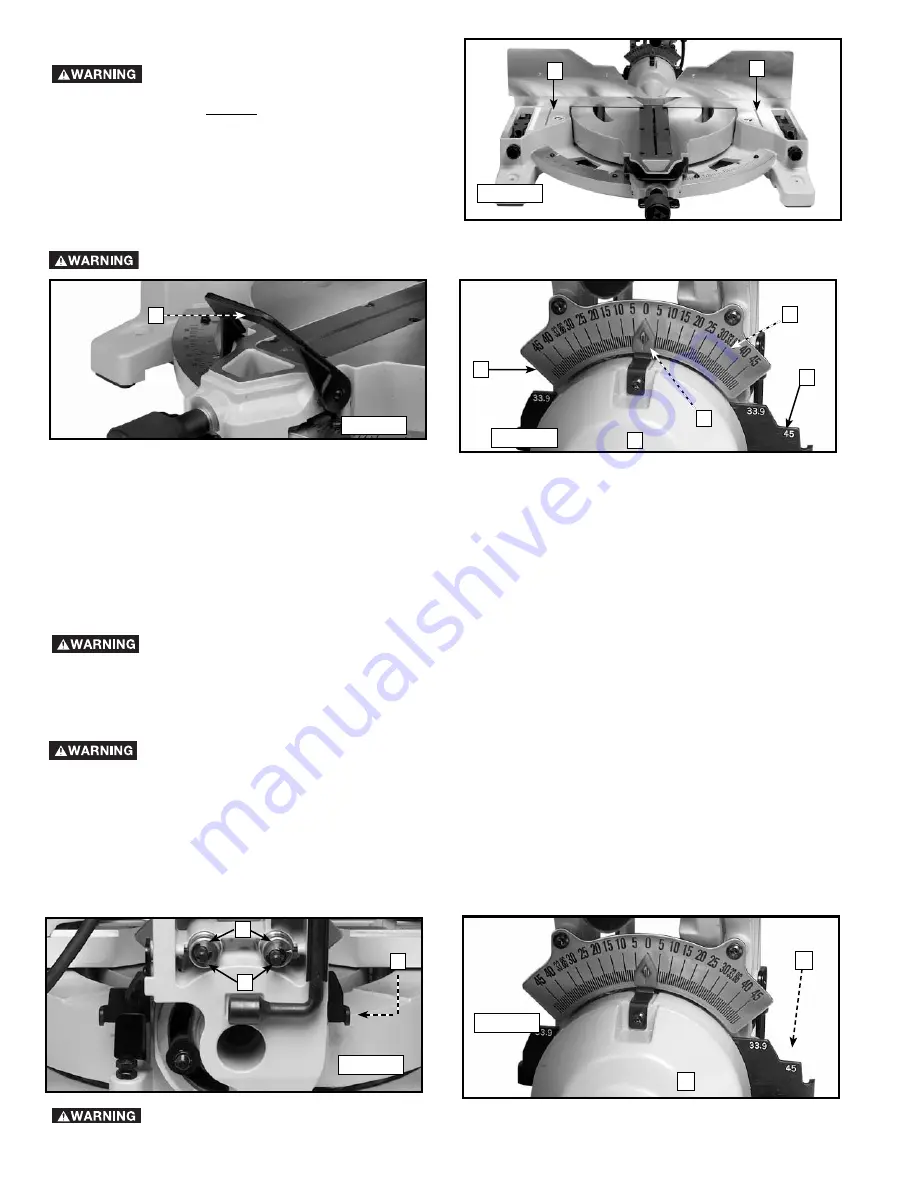

TABLE HAZARD ZONE

THE AREA INSIDE THE TWO RED

LINES (A) FIG. 17 ON THE TABLE IS DESIGNATED

AS A HAZARD ZONE. NEVER PLACE YOUR HAND(S)

INSIDE THE "TABLE HAZARD ZONE" (WITHIN THE

RED LINES) WHILE THE TOOL IS BEING OPERATED.

CLAMP ALL WORKPIECES WHICH WOULD CAUSE

YOUR HAND(S) TO BE WITHIN SIX INCHES OF THE

SAW BLADE.

A

A

Fig. 17

IMPORTANT: Move the sliding fence to the left or right to provide clearance for the blade and guard. The DEGREE of

tilt determines how far to move the sliding fence. Refer to the section “ADJUSTING SLIDING FENCE.”

TILTING THE CUTTINGHEAD FOR BEVEL CUTTING

DISCONNECT MACHINE FROM POWER SOURCE.

1.

The cuttinghead of your compound miter saw can be tilted to cut any bevel angle from a 90° straight cut-off to a 48° bevel

angle left or right. Raise bevel lock lever (A) Fig. 18.

2. Positive stops (A) Fig. 19 are provided to rapidly position the saw blade at 0°, 33.9° and 45°. Refer to the section of

this manual titled

“SELECTING 0°, 33.9

°,

AND 45° BEVEL POSITIVE STOPS.”

The bevel angle of the cuttinghead is

determined by the position of the pointer (B) on the scale (C).

3. In addition, a marked indicator (D) is provided on the bevel scale (33.9°) for cutting crown moulding. Refer to the

“CUTTING CROWN MOULDING”

section of this manual.

A

Fig. 18

DISCONNECT MACHINE FROM POWER SOURCE.

1. Position the bevel detente plate so that the desired angle (A) Fig. 20 is exposed immediately to the left or right of the

housing (H) Fig. 21.

2. Lift the bevel lock lever (A) Fig. 18 to disengage the bevel lock.

3. Tilt the cuttinghead left or right as desired until it stops on plate (A) Fig. 20.

NOTE:

Fig. 21 illustrates the sliding plate

positioned for 33.9° left or right.

4. Lower the the bevel lock lever (A) Fig. 18 to engage the bevel lock.

NOTE:

To perform a bevel cut of more than 45°, pull the bevel pin (B) Fig. 20 out to bypass the bevel detent plate. 48° is

possible.

SELECTING 0°, 33.9°, AND 45° BEVEL POSITIVE STOPS

Make sure that the fence is clear of the guard and blade before operating the saw.

The bevel setting feature utilizes a sliding plate (A) Fig. 20, pin (B), and bushing (C) design that is used to select the bevel

angle. The position of the pin (B) and the sliding plate (A) determine the bevel angle.

Fig. 21

H

A

Take care not to pinch the cord when tilting the cuttinghead.

A

D

B

H

C

Fig. 19

C

B

A

Fig. 20