Catalog Number

Blade Description

Plate

Kerf

Hook

Bore

HardwoodSoftwood Plywood Compositions

1-Sided Laminates

2-Sided Laminates

Non-ferrous Metal

Tile/Asbestos

Solid PlasticHard Fiber/Paper

Rip

Trim Cut

With Grain

Trim Cut

Across Grain

Material

Application

29

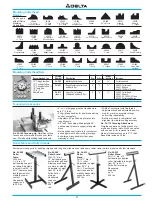

Flat Top Grind (FT). Generally, for

cutting material with grain. Larger

gullets on this type blade accept

greater chip loads; permit higher

feed rates. Excellent for ripping on

either single or multi rip machines

where speed of cut is more impor-

tant than quality of cut. Teeth with

square or flat top shape act as

chisels, cutting material with chis-

el-like action. Also serve as rakers

to clean out the cuttings or chips.

Triple Chip & Flat Grind (TC&F).

Two shapes of teeth—alternate

triple-edge and flat top design for

dual action cutting. Triple-edge

teeth chip down center of kerf; flat

top raker teeth follow to clean out

material from both sides. TC&F

blades with negative hook angle

are recommended for cutting non-

ferrous metals. Negative hook

angle prevents climbing; gives you

total control over the feed rate.

Alternate Top Bevel & Raker

(ATB&R). Excellent for cutting

operations both with and/or across

the grain. Achieves a fairly high

level of quality over wide range of

cuts. Two sets of shearing-action

alternate left and right top bevel

teeth followed by a raking action

flat top tooth with large round gul-

let to facilitate chip removal.

Alternate Top Bevel Grind (ATB).

For across the grain cutting and/or

cut-off and trimming operations on

undefined grain work. Top bevel

shaped teeth sever the material

with shearing action alternately left

and right. Given a choice, the ATB

blade with the higher number of

teeth will produce the higher quali-

ty of finish cut.

Four Popular Tooth Designs

Industrial Carbide-Tipped Circular Saw Blades

SAW ACCESSORIES

Designed, engineered and manufactured to

uncompromising quality standards for optimum

cutting performance and maximum service life.

Check their many fine features:

●

Fine-grain carbide tips, highly resistant to wear.

●

Chrome alloy steel body, balanced for running

accuracy.

●

Expansion slots to dissipate heat;

prevent warping. With copper rivet inserts to

reduce noise level.

●

Tips silver brazed to body,

impact tested to guarantee set.

●

Tooth clearance

angle precision-ground for smoothness.

Select the right blade with the appropriate tooth design for the material to be cut on your particular job!

To use the chart below: First refer to the proper machinery section. Next, find the blade with the highest rating under the material column that

best applies to your work. If you are looking for a general purpose blade, look for consistent ratings under the materials you work with most.

Or—refer to the far right hand column for the best finish rating for type of cut.

Miter Boxes, Sawbuck, Radial Saw and Other Pendulum Type Saws

35-593

8

Ó

x 48 TC&F

.079

.110

-6°

5

/

8

Ó

10

10

8

8

10

10

10

8

10

8

F

F

35-600

9

Ó

x 72 TC&F

.086

.118

-6°

5

/

8

Ó

10

10

8

8

10

10

10

8

10

8

F

F

35-619

10

Ó

x 60 TC&F

.094

.118

-6°

5

/

8

Ó

9

9

7

8

9

9

9

7

9

7

F

F

35-625

10

Ó

x 80 TC&F

.094

.118

-6°

5

/

8

Ó

10

10

8

8

10

10

10

8

10

8

F

F

35-646

12

Ó

x 60 TC&F

.102

.126

-6°

5

/

8

Ó

9

9

7

8

9

9

9

7

9

7

F

F

35-654

12

Ó

x 80 ATB

.086

.126

-6°

1

Ó

9

9

7

9

10

10

na

na

na

8

F

35-655

12

Ó

x 96 TC&F

.095

.142

5°

5

/

8

Ó

7

7

10

10

9

8

na

na

5

7

F

F

F

Circular Saws

35-590

8

Ó

x 48 TC&F

.079

.110

5°

5

/

8

Ó

8

8

5

5

6

4

10

5

10

5

F

F

35-591

8

Ó

x 24 ATB/SB .079

.118

10°

5

/

8

Ó

10

10

8

8

8

5

na

na

4

4

M

M

F

35-592

8

Ó

x 64 ATB

.079

.118

8°

5

/

8

Ó

6

6

10

10

9

8

na

na

7

10

M

M

35-594

8

Ó

x 48 ATB

.079

.118

5°

5

/

8

Ó

7

8

8

9

10

7

na

na

na

7

M

F

35-603

9

Ó

x 24 ATB

.079

.118

15°

5

/

8

Ó

8

8

8

7

7

4

na

na

na

7

M

M

M

35-604

9

Ó

x 64 ATB

.079

.118

10°

5

/

8

Ó

6

6

9

10

9

8

na

na

8

10

M

M

35-606

9

Ó

x 40 ATB&R

.086

.126

15°

5

/

8

Ó

10

10

8

8

na

na

na

na

na

na

M

35-611

10

Ó

x 18 FT

.086

.118

20°

5

/

8

Ó

10

10

8

8

na

na

na

na

na

na

M

35-612

10

Ó

x 24 ATB/SB .086

.126

20°

5

/

8

Ó

10

10

8

8

8

6

na

na

na

5

F

M

F

35-613

10

Ó

x 40 ATB

.086

.126

12°

5

/

8

Ó

8

8

9

9

7

6

na

na

na

na

M

M

35-614

10

Ó

x 48 ATB

.086

.126

12°

5

/

8

Ó

9

9

10

10

8

7

na

na

na

na

F

F

35-616

10

Ó

x 60 ATB

.086

.126

12°

5

/

8

Ó

7

8

8

9

10

7

na

na

na

7

M

F

35-617

10

Ó

x 50 ATB&R

.086

.126

15°

5

/

8

Ó

10

10

8

8

na

na

na

na

na

na

F

F

F

35-618

10

Ó

x 60 TC&F

.086

.126

12°

5

/

8

Ó

8

7

8

8

5

3

na

10

na

10

M

F

35-620

10

Ó

x 72 ATB

.086

.126

8°

5

/

8

Ó

9

8

7

5

10

7

na

3

3

na

F

M

35-623

10

Ó

x 80 ATB

.086

.126

8°

5

/

8

Ó

5

6

8

10

9

4

na

na

na

10

M

F

35-624

10

Ó

x 80 TC&F

.086

.126

10°

5

/

8

Ó

5

5

7

7

9

10

na

na

10

na

F

F

35-641

12

Ó

x 24 FT

.095

.142

20°

1

Ó

10

10

8

8

na

na

na

na

na

na

M

35-642

12

Ó

x 36 ATB/SB .095

.142

15°

1

Ó

10

10

8

8

8

6

na

na

4

6

F

M

M

35-644

12

Ó

x 48 ATB

.095

.142

15°

1

Ó

7

7

9

9

7

6

na

na

na

na

M

M

35-645

12

Ó

x 60 TC&F

.095

.142

10°

1

Ó

10

10

10

9

10

9

na

10

na

9

35-648

12

Ó

x 96 TC&F

.095

.142

10°

1

Ó

5

5

7

7

9

10

na

na

10

na

F

F

35-649

12

Ó

x 96 ATB

.095

.142

10°

1

Ó

5

6

7

10

9

4

na

na

na

9

F

M

35-656

12

Ó

x 60 ATB

.126

.173

10°

5

/

8

Ó

9

9

9

8

8

7

na

na

na

8

F

M

F

35-657

12

Ó

x 60 ATB&R

.086

.126

15°

1

Ó

10

10

8

8

na

na

na

na

na

na

F

F

F

Special High-Performance Blades (30° alternate top bevel shaped teeth) for Chip-Free Cutting of Melamine, Coreboard;

Laminates and Other Man-made Materials

35-741

8

Ó

x 64 ATB

.079

.118

-6°

5

/

8

Ó

6

6

10

10

10

10

na

na

na

10

F

F

35-742

10

Ó

x 80 ATB

.086

.126

-6°

5

/

8

Ó

6

6

10

10

10

10

na

na

na

10

F

F

35-633

10

Ó

x 80 TC&F

.086

.126

0°

5

/

8

Ó

na

na

7

10

8

8

na

na

8

8

Blade descriptions

contain the following

information: the first

number is the blade

diameter followed

by the number of

saw teeth and letters

indicating tooth

configuration.

FT: Flat Top Grind

TC&F: Triple Chip &

Flat Grind

ATB: Alternate Top

Bevel Grind

ATB&R: Alternate

Top Bevel & Raker

SB: Safety Blade

Design with Chip

Inhibitor

The tooth designs

listed above are

explained in detail on

the previous page.

F = Fine

M = Medium

Ten (10) rating indi-

cates blade works

best cutting that type

of material.