7

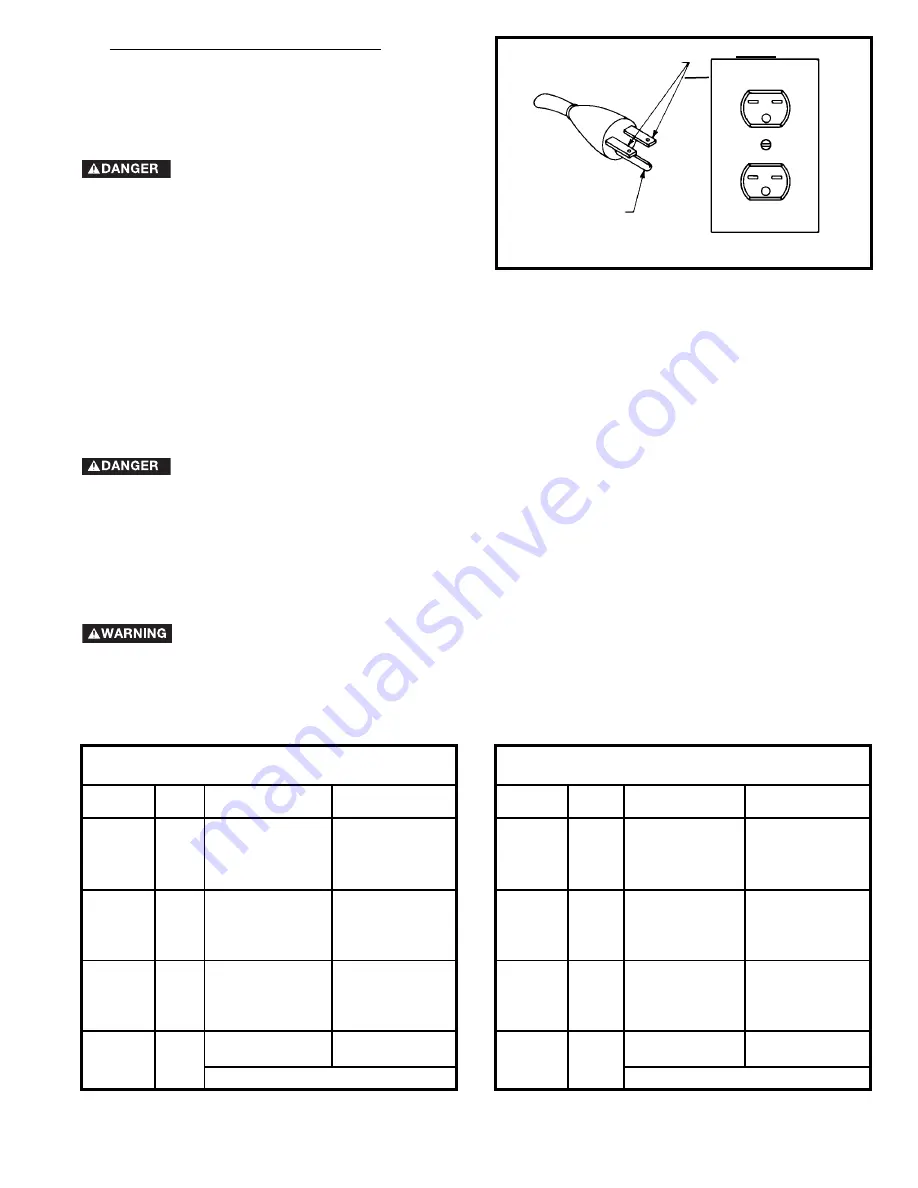

Fig. C

GROUNDED OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

EXTENSION CORDS

Use proper extension cords. Make sure your extension cord is in good condition and is a 3-wire

extension cord which has a 3-prong grounding type plug and matching receptacle which will accept the machine’s

plug. When using an extension cord, be sure to use one heavy enough to carry the current of the machine. An

undersized cord will cause a drop in line voltage, resulting in loss of power and overheating. Fig. D-1 or D-2, shows

the correct gauge to use depending on the cord length. If in doubt, use the next heavier gauge. The smaller the gauge

number, the heavier the cord.

Fig. D-1

Fig. D-2

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Ampere

Total Length

Gauge of

Rating

Volts

of Cord in Feet

Extension Cord

0-6

120

up to 25

18 AWG

0-6

120

25-50

16 AWG

0-6

120

50-100

16 AWG

0-6

120

100-150

14 AWG

6-10

120

up to 25

18 AWG

6-10

120

25-50

16 AWG

6-10

120

50-100

14 AWG

6-10

120

100-150

12 AWG

10-12

120

up to 25

16 AWG

10-12

120

25-50

16 AWG

10-12

120

50-100

14 AWG

10-12

120

100-150

12 AWG

12-16

120

up to 25

14 AWG

12-16

120

25-50

12 AWG

12-16

120

GREATER THAN 50 FEET NOT RECOMMENDED

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Ampere

Total Length

Gauge of

Rating

Volts

of Cord in Feet

Extension Cord

0-6

240

up to 50

18 AWG

0-6

240

50-100

16 AWG

0-6

240

100-200

16 AWG

0-6

240

200-300

14 AWG

6-10

240

up to 50

18 AWG

6-10

240

50-100

16 AWG

6-10

240

100-200

14 AWG

6-10

240

200-300

12 AWG

10-12

240

up to 50

16 AWG

10-12

240

50-100

16 AWG

10-12

240

100-200

14 AWG

10-12

240

200-300

12 AWG

12-16

240

up to 50

14 AWG

12-16

240

50-100

12 AWG

12-16

240

GREATER THAN 100 FEET NOT RECOMMENDED

3.

240 VOLT SINGLE PHASE OPERATION:

The motor supplied with your saw is a dual voltage,

120/240 volt motor. If it is desired to operate your saw at

240 volts, single phase, it is necessary to reconnect the

motor leads in the motor junction box by following the

in-structions given on the motor nameplate.

MAKE SURE MOTOR IS DISCONNECTED

FROM POWER SOURCE BEFORE RECONNECTING

MOTOR LEADS

.

It is also necessary to replace the 120 volt plug, supplied

with the motor, with a UL/CSA Listed plug suitable for

240 volts and the rated current of the saw as illustrated

in Fig. C. Contact your local Authorized Delta Service

Center or qualified electrician for proper procedures to

install the plug. The saw must comply with all local and

national electrical codes after the 240 volt plug is

installed.

The saw with a 240 volt plug should only be connected

to an outlet having the same configuration as the plug

illustrated in Fig. C. No adapter is available or should be

used with the 240 Volt plug.

IN ALL CASES, MAKE CERTAIN THE

R E C E P TA C L E I N Q U E S T I O N I S P R O P E R LY

G R O U N D E D . I F Y O U A R E N O T S U R E H AV E A

QUALIFIED ELECTRICIAN CHECK THE RECEPTACLE.