10

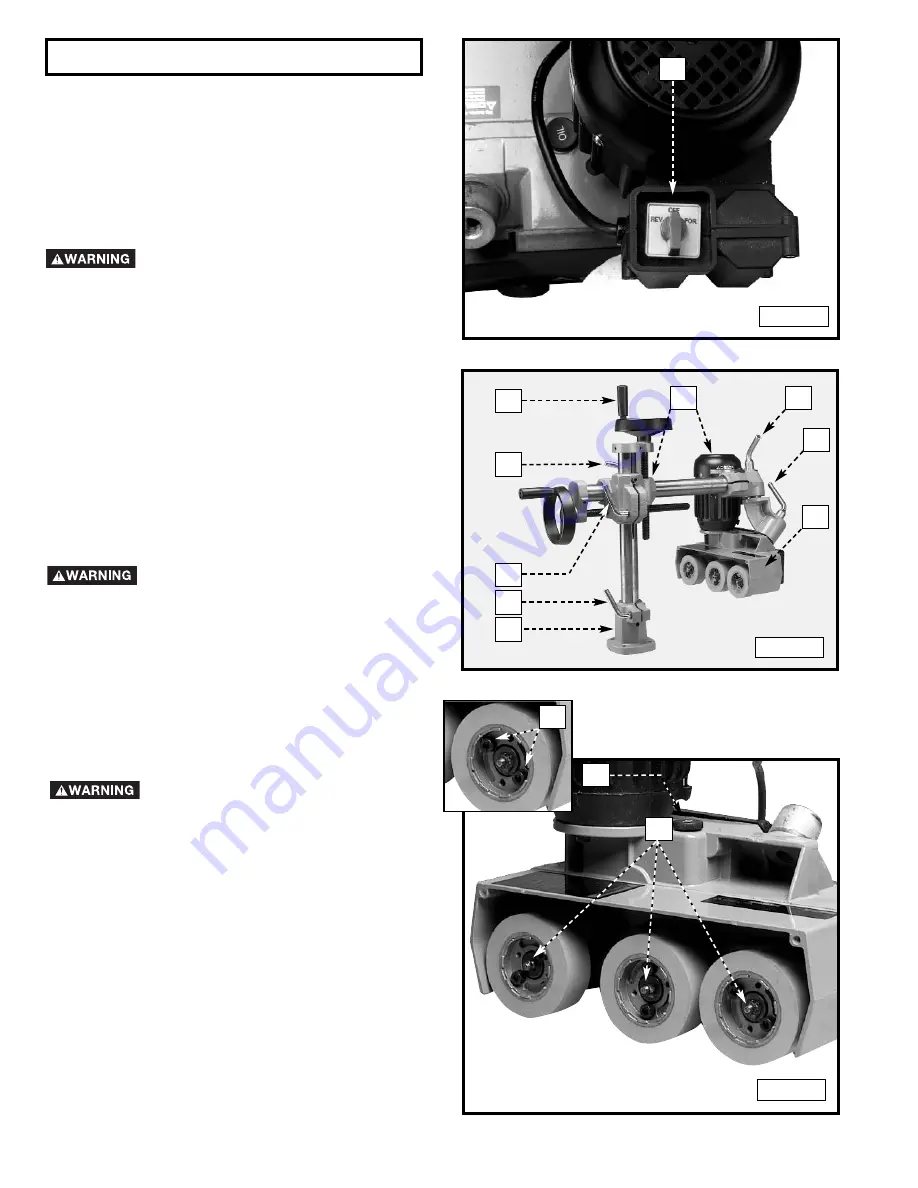

MOTOR CONTROL SPEED SWITCH

To operate the feeder in a forward position, turn switch

(A) Fig. 7 clockwise. To operate the feeder in the oppo-

site direction, turn switch (A) counterclockwise.

MACHINE USE

OPERATING CONTROLS

1.

You can rotate the entire feeder assembly (A) Fig. 8

360 degrees in the mounting bracket (B) by loosen-

ing the locking lever (C).

2.

To raise or lower the feeder assembly (A) Fig. 8,

loosen the locking lever (D) and rotate the hand-

wheel (E).

3.

To move the feeder assembly (A) Fig. 8 in or out,

loosen the locking lever (G) and rotate the hand-

wheel (H).

4.

To adjust the position of the feeder (F) Fig. 8, loosen

the locking levers (K) and/or (L).

5.

Tighten all locking levers after adjustments are com-

pleted.

FEED ROLLER REPLACEMENT

You can remove each feed roller (A) Fig. 9 to repair or re-

place by removing the two screws (B) inset, then remov-

ing the feed roller. Install the new or repaired feed rollers

and secure with the two screws (B).

LUBRICATION

Disconnect machine from power source!

Disconnect machine from power source!

Disconnect machine from power source!

A

A

B

C

D

E

A

K

L

F

Fig. 8

Fig. 9

Fig. 7

A

B

Lubricate the feed rollers approximately every 200 hours

of use with grease through the grease fittings (A) Fig. 9

using the grease gun supplied with the machine.

Periodically, coat the gear chains with light machine oil.

Change the gear oil after every 1000 hours of use or

after heavy extended use. Replace the old oil with #90

weight gear oil. To gain access to the gear oil chamber,

turn the oil cap (C) Fig. 9 counter-clockwise. The oil level

should consistently be 2" to 2-1/4" below the top of the

gear case.

C

Summary of Contents for 36-850

Page 14: ...14 NOTES ...

Page 15: ...15 NOTES ...