Page 1

212294 Rev.

B

591T__ 2 __ __

Write purchase model number here for future reference

PLEASE LEAVE this M&I Sheet with the owner, maintenance plumber, etc. as

items relating to ongoing maintenance suggestions and procedures are included.

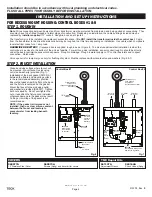

NOTE:

Control Box #0 and #1 are designed for routine

171°F (77°C) disinfection cycles up to 30 minutes.

Control Box #8 is not recommended for high temperature

disinfection cycles as the thermostatic mixing valve limits

the higher temperature flow output.

NOTE:

For optimum performance of this product, we

recommend a system pressure between 20 and 80 PSI

static. This product will operate up to a maximum of 125

PSI static per ANSI and CSA requirements. However,

we do not recommend pressure above 80 PSI. Thermal

expansion or leaking pressure reducing valves may

require use of expansion tanks or relief valves to ensure

your system never exceeds its maximum intended

pressure setting.

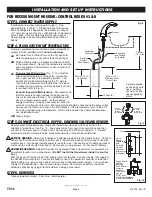

060638A

Vandal Resistant Laminar Outlet

with Antimicrobial by Agion

®

1.5 GPM (5.7 L/min)

060640A

Vandal Resistant Flow Control

Aerator and Wrench

1.5 GPM (5.7 L/min)

061203A

Vandal Resistant Laminar

Outlet with Wrench

0.5 GPM (1.9 L/min)

061176A

Vandal Resistant Laminar

Outlet with Wrench

1.0 GPM (3.8 L/min)

061104A

Vandal Resistant Flow Control

Non-Aerating Spray Outlet

with Wrench

0.35 USGPM (1.3 L/min)

RP31704 - Optional

Vandal Resistant Spray

Outlet with Wrench

0.5 GPM (1.9 L/min)

060566A

- Optional

Vandal Resistant Spray

Outlet with Wrench

1.0 GPM (3.8 L/min)

RP6001

Nut & Washer

060765A

Wrench

063211A

Spout Assembly

Fig. 1

062032A

Braided Polymer Hose

OPTION LIST

TRANSFORMERS

060704A

Transformer 110 to 24 VAC 20VA

up to 5 Electronic Valves

060771A

Transformer 110 to 24 VAC 40VA

up to 10 Electronic Valves

212294

212294

212294 212294 212294

212294

212294

212294 212294 212294

061031A

Deck Gasket (3/pkg)

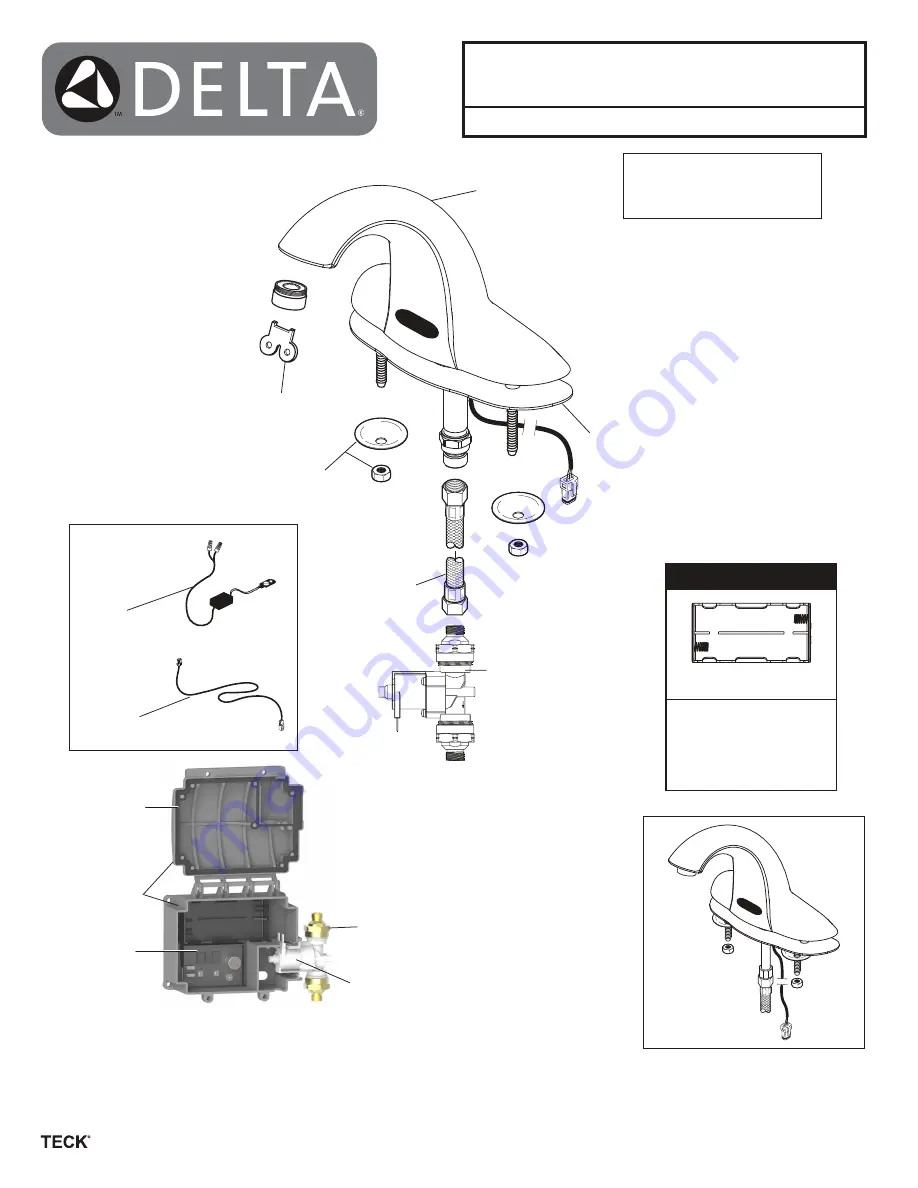

Note:

See page 3 for

parts breakdown on

recessed mount boxes.

w w w . s p e c s e l e c t . c o m

060683A

24 VAC/6.4 VDC

Converter

061256A

36” Cable Extension

Accessories

060681A

Battery Holder

063257A

3/4” Solenoid Valve

w/adaptors for 3/8”

Compression

063258A

Surface Box Assembly (less driver board)

w/ 3/4” solenoid and adaptors for 3/8” compression

060908A

Solenoid Holder

063257A

3/4” Solenoid Valve

w/adaptors for 3/8”

Compression

061252A

Dual Driver

Board Masco

H2Optics

& Proximity

060906A

Surface

Mount Housing

060905A

Cover Gasket