Page 3

212294 Rev.

B

w w w . s p e c s e l e c t . c o m

FOR RECESS MOUNT HOUSING: CONTROL BOXES #1 & 8

INSTALLATION AND SET UP INSTRUCTIONS

Installation should be in accordance with local plumbing and electrical codes.

FLUSH ALL PIPES THOROUGHLY BEFORE INSTALLATION.

COVERS

060073A

Screws (4/pkg) and driver bit for covers

060577A

12” Stainless Steel Cover

TMV Repair Kits

061137A

Adjustment Wrench

STEP 1. ROUGH IN

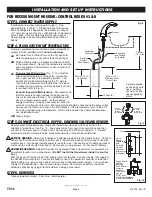

STEP 2. FAUCET INSTALLATION

Note:

Wires connecting between box(es) and from transformer must be protected from abrasion, and being pulled at connections. They

also may have to be fished through at a later stage of construction. Depending on installation, the cable bushings included may be

replaced by

installer supplied

1/2” conduit. Rough-in box as per Figure 8.

The transformer is to be installed in an adjacent accessible space. (

Do NOT install the transformer inside the control box.)

Cable

from the transformer to the driver board/controller may be roughed in at this time depending on installation. Use cable which complies to

local electrical codes for a 1 amp load.

HARDWIRE OR BATTERY

:

If recessed box is supplied, rough in as per Figure 8. The most vandal resistant installation is when the

control box is as close to the bottom of the sink as feasible. For wall hung sink installation, sensor conduit rough in should be directly

under the basin to minimize sensor cord exposure. Rough in drainage. Rough in water supply to 10” control box inlets and to spout

connection. Finish walls.

Valve spacer is for temporary use only for flushing of system. Must be replaced with solenoid valve and washers (Fig. 6 & 7).

Clean deck/sink surface where faucet will

be mounted. Mount faucet to sink using

nut(s) and washer(s) provided (Fig. 1).

Installation of the deck gasket (061031A)

between the fixture and mounting surface

is the recommended assembly practice.

Ensure that gasket is sitting flat on the deck

and the fixture is centered on the gasket.

Mount the faucet to the sink using nut(s)

and washer(s) provided (RP6001). Tighten

both nuts equally. Do not overtighten the

nut or reposition the fixture once installed,

otherwise damage to the gasket may result.

Cutting or trimming of the gasket is not

recommended.

NOTE: If the gasket is trimmed or not

installed, then use clear silicone sealant

between the faucet and lavatory to

prevent water from leaking beneath

lavatory.

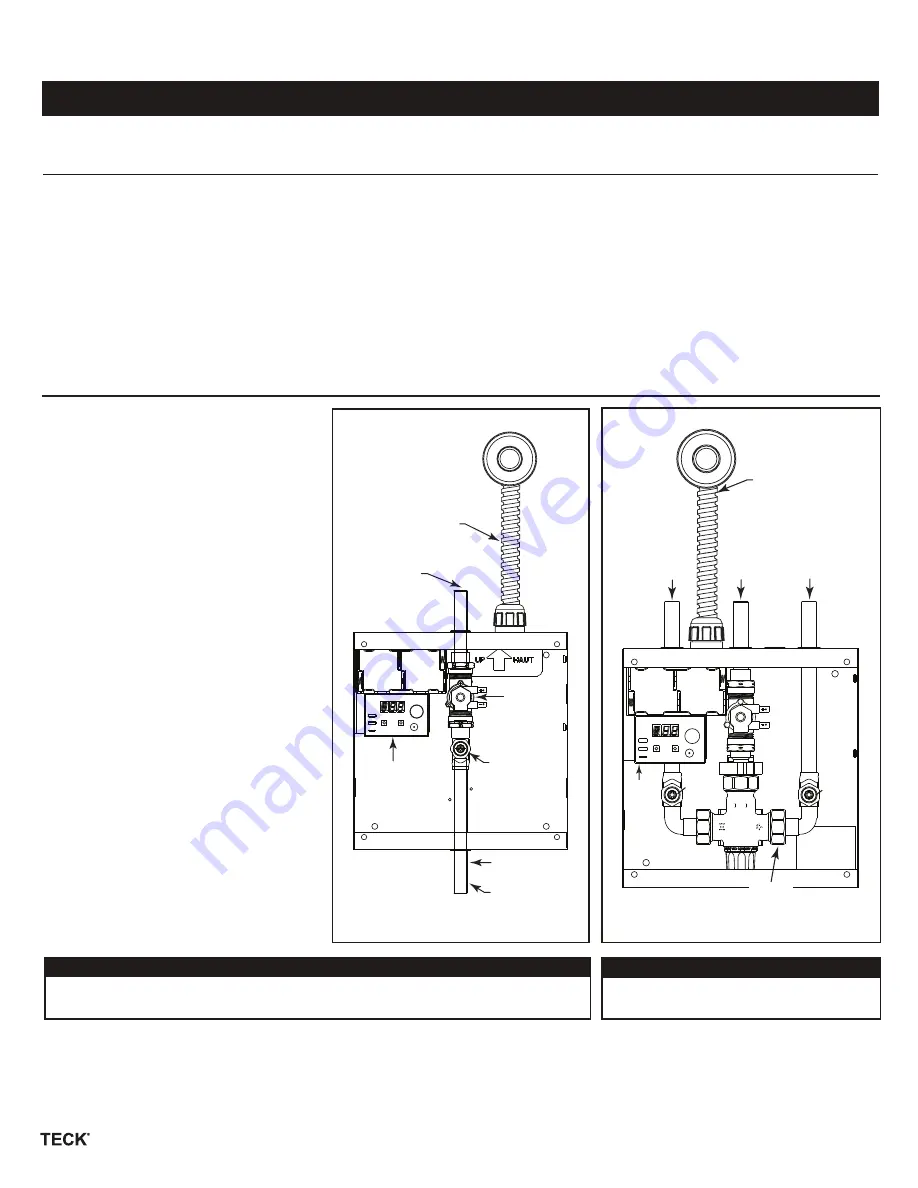

Control Box #1

Fig. 6

Control Box #8

Fig. 7

Tempered Water

(By Others)

Inlet:

1/2” Sweat

060671A

3/4” NPS

Solenoid

Valve &

Washers

061252A

Driver board

to be located

on bracket

063135A

Stop Kit

1/2” Sweat

Outlet

061252A

Driver

board

to be

located

on

bracket

063135A

Stop Kit

063135A

Stop Kit

Hot Inlet

1/2” Sweat

1/2” Sweat

Outlet

Cold Inlet

1/2” Sweat

063179A

Thermostatic Mixing Valve

with checks & gaskets

Flexible Sensor

Cord Conduit

(supplied on Recessed

Mount Box)

Flexible Sensor

Cord Conduit

(supplied on

Recessed Mount Box)

063164A

Check Valves (2/pkg)