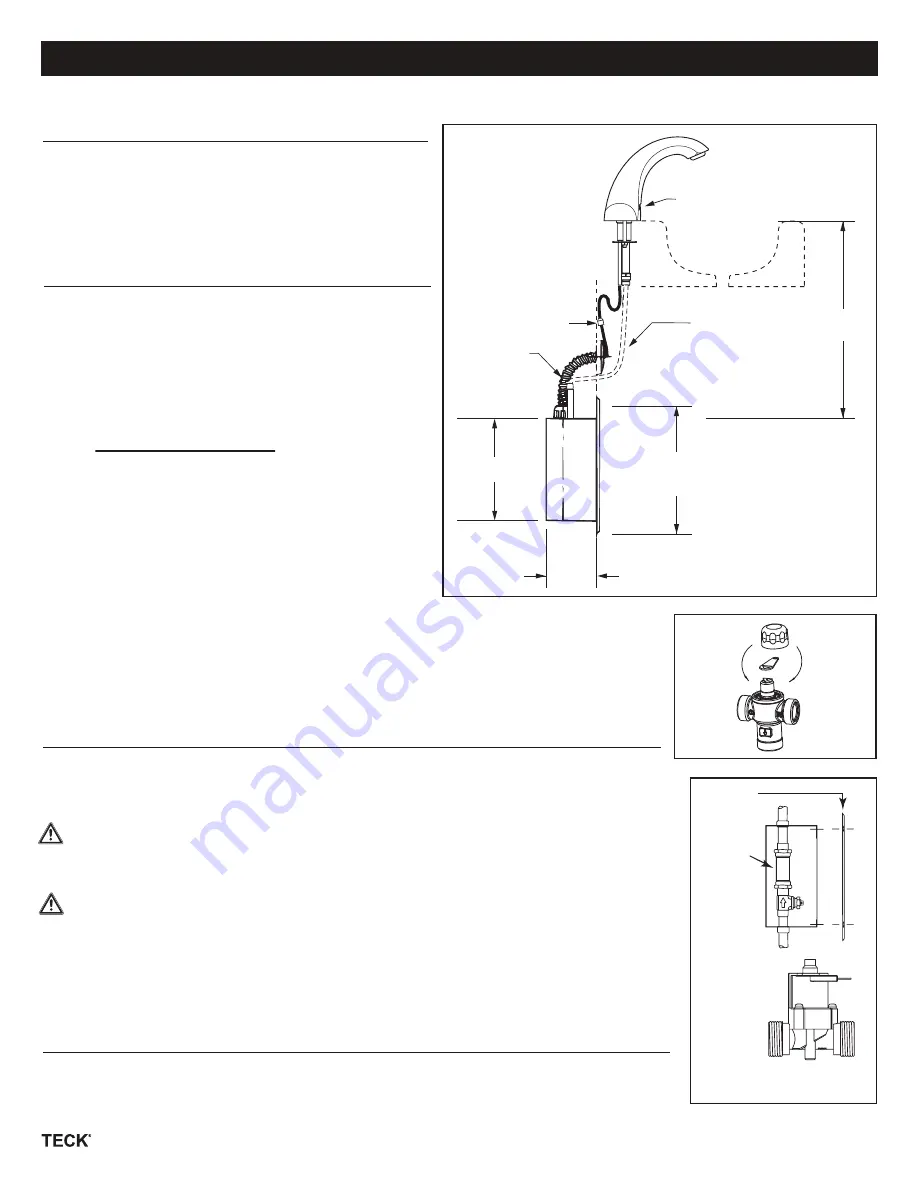

Watertight

Connector

Flexible

Sensor

Cord Conduit

257mm (10.13")

Control Box

305mm (12")

Stainless Steel

Cover Plate

102mm (4")

355mm

(14”) max.

Fig. 8

Product supplied

as shown by solid

lines. All items

shown by dotted

lines supplied by

others.

Sensor

Page 4

212294 Rev.

B

FOR RECESS MOUNT HOUSING: CONTROL BOXES #1 & 8

STEP 3. CONNECT WATER SUPPLY

Install sink and connect drainage to rough in. See

applicable Fig. 6

or Fig. 7. Please note that the connec-

tion and fittings are supplied by the installer to connect

1/2” nominal sweat at the box outlet and 3/8” compression

at the spout. Connect water supply through to spout.

Assure supply lines are completely flushed and free of

debris.

STEP 4. FLUSH SYSTEM/SET TEMPERATURE

Remove coverplate from control box. Open screwdriver

stop(s) to flush installation for

1 minute minimum.

4A

Run water for a sufficient time so the hot and cold

water supplies are as hot and cold as they will get.

4B

Place a thermometer in a plastic container and hold

in the water stream. Record the temperature reading

and note position of temperature control, and lock at

desired setting.

4C

Thermostatic Mixing Valve

(Fig. 7) To adjust the

mixed outlet temperature of the valve, remove the

cap to gain access to the adjusting spindle. The

spindle should be rotated towards the “C” side to

reduce the temperature and towards the “H” side to

increase the temperature - until the desired set point

is reached (refer to Fig. 9).

Periodic Inspection/Maintenance

- We recommend

that this valve is checked at least once per year to

ensure its continued function. For installations with

poor or unknown water quality, or other adverse

supply conditions, it may be necessary to check the

valve at more frequent intervals. The temperature should be checked at the same outlet

as was used for commissioning in the first instance. If the temperature is more than 3°F

from the commissioning in temperature, refer to the included Cash Acme Maintenance

and Installation Guide.

4D

Close stop(s).

STEP 5. CONNECT ELECTRICAL SUPPLY, SOLENOID VALVE AND SENSOR

Remove plastic threaded spacer nipple and install solenoid valve with body arrow in the

direction of water flow. See Fig. 10. Feed sensor wire from spout into control box and then

connect to the driver board. Connect red solenoid wire from the driver board to “+” marked

solenoid terminal on solenoid valve, black solenoid wire to other solenoid terminal.

BATTERY VERSION

Install four “Alkaline C” batteries provided into the battery holder. Connect

battery clip from the driver board to battery pack. Ensure snap does not touch any conductive

metal surface. Two beeps indicate power is ready for use. Use caution not to damage wires or

components on electronic driver board. Secure cover using screws. Do not use 9V battery.

HARDWIRE VERSION

Install CSA and/or UL approved Class 2 transformer or equivalent in a

convenient location or in a pipe chase.

(Do NOT install the transformer inside the control

box.)

With the power off, bring the 24 VAC supply wires into the box. Connect the 24 VAC supply to

the 060683A conversion kit. Connect the battery snap of the hardwire converter to the driver

board battery clip. Ensure snap does not touch any conductive metal surface. Turn on power

supply for the transformer. Secure cover using screws. Do not remove battery snap from

hardwire converter by using a flat screwdriver, damage may result.

STEP 6. SERVICES

Open screwdriver stop(s). Flush line. Install aerator.

Cover

Fig. 10

Valve

Spacer

(Replace

with

Solenoid

Valve &

Washers

after system

is flushed)

Solenoid Valve

(INSTALL:

replacing

SPACER after

system is

flushed.)

SOLENOID

may be

ROTATED to

ALLOW for installation

of COVER ASSEMBLY.

INSTALLATION AND SET UP INSTRUCTIONS

w w w . s p e c s e l e c t . c o m

Connection

and Fittings

by Installer

Fig. 9

Towards

“H” side to

increase

temperature

Towards

“C” side

to reduce

temperature