Chapter 11 Description of Parameter Settings

|

C200 Series

11-84

When Pr.06-06 and Pr.06-09 are set to 1 or 3, it will display a warning message and won’t have an

abnormal record.

When Pr.06-06 and Pr.06-09 are set to 2 or 4, it will display a warning message and will have an

abnormal record.

Over-torque Detection Level (OT1)

Factory Setting: 120

Settings 10 to 250% (100%: drive’s rated current)

Over-torque Detection Level (OT1)

Factory Setting: 0.1

Settings 0.0~60.0 sec

Over-torque Detection Level (OT2)

Factory Setting: 120

Settings 10 to 250% (100%: drive’s rated current)

Over-torque Detection Time (OT2)

Factory Setting: 0.1

Settings 0.0~60.0 sec

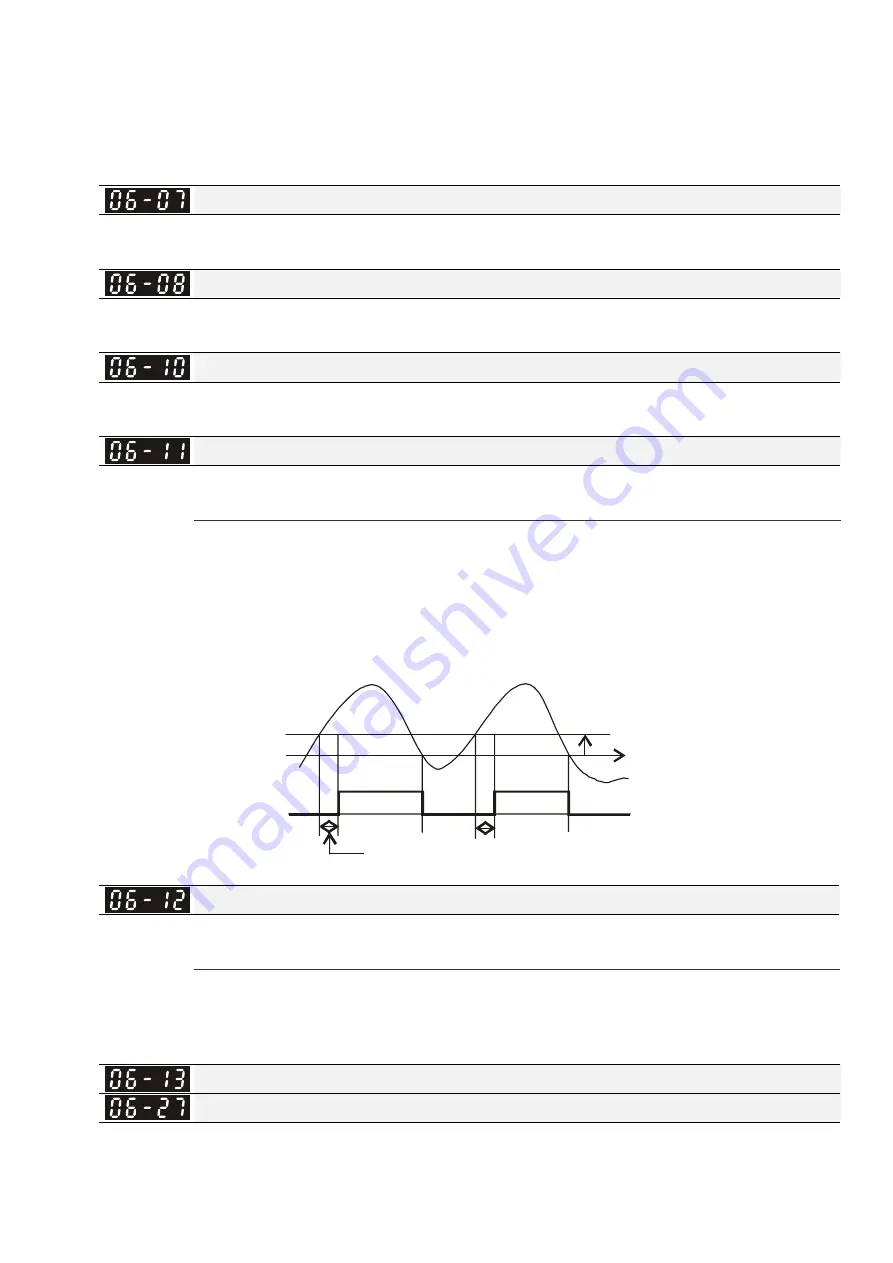

Over torque detection is determine by the following method: if the output current exceeds the

over-torque detection level (Pr.06-07, factory setting: 150%) and also exceeds Pr.06-08

Over-Torque Detection Time, the fault code “ot1/ot2” will appear. If a Multi-Functional Output

Terminal is to over-torque detection (setting 7 or 8), the output is on. Please refer to

Pr.02-13~02-14 for details.

5%

Pr.06-07,

Pr.06-10

Pr.06-08, 06-11

current

Current Limit

Factory Setting: 150

Settings 0~250% (100%: drive’s rated current)

Pr.06-12 sets the maximum output current of the drive. Pr.06-12 and Pr.11-17 ~ Pr.11-20 are used

to set the drive’s output current limit. When the drive is in VF, SVC or VFPG control mode, output

frequency will decreases as the output current reaches current limit. It is a current stall prevention.

Electronic Thermal Relay Selection (Motor 1)

Electronic Thermal Relay Selection (Motor 2)

Factory Setting: 2

Settings 0: Inverter motor

Call 1(800)985-6929 for Sales

deltaacdrives.com

sales@deltaacdrives.com

Call 1(800)985-6929 for Sales

deltaacdrives.com

sales@deltaacdrives.com