Chapter 14 PLC Function

|

C200 Series

14-15

14.4.4 The Example for Designing Basic Program

Start, Stop and Latching

In the same occasions, it needs transient close button and transient open button to be start and stop

switch. Therefore, if you want to keep the action, you should design latching circuit. There are

several latching circuits in the following:

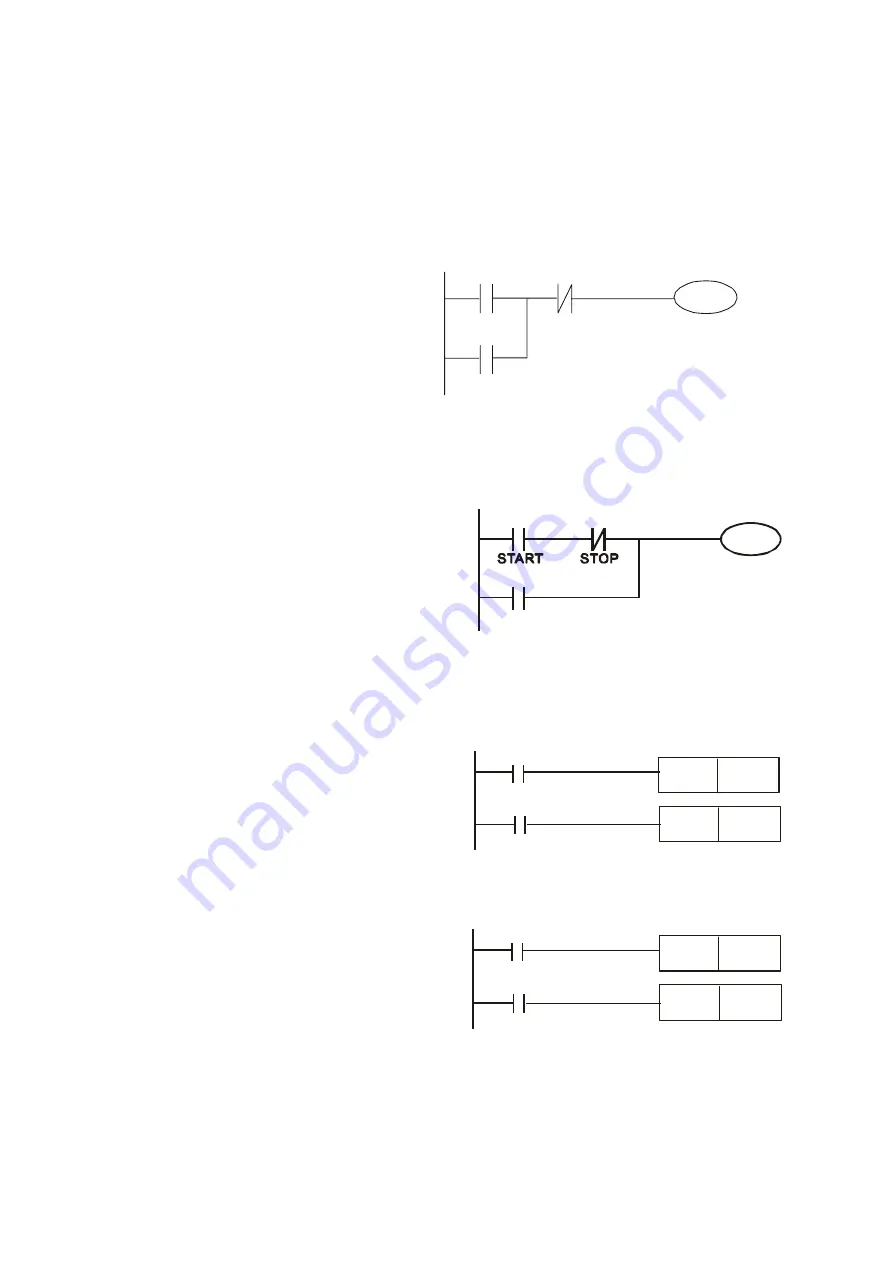

Example 1: the latching circuit for priority of stop

When start normally open contact X1=On,

stop normally contact X2

=

Off, and Y1=On

are set at the same time, if X2=On, the coil

Y1 will stop acting. Therefore, it calls

priority of stop.

Y1

X2

X1

START

STOP

Y1

Example 2: the latching circuit for priority of start

When start normally open contact X1=On,

stop normally contact X2

=

Off and Y1=On

(coil Y1 will be active and latching) are valid

at the same time, if X2=On, coil Y1 will be

active due to latched contact. Therefore, it

calls priority of start.

X2

Y1

X1

Y1

Example 3: the latching circuit of SET and RST commands

SET

Y1

RST

Y1

X1

X2

Top priority of stop

The figure at the right side is latching circuit

that made up of RST and SET command.

It is top priority of stop when RST command

is set behind SET command. When

executing PLC from up to down, The coil Y1

is ON and coil Y1 will be OFF when X1 and

X2 act at the same time, therefore it calls

priority of stop.

It is top priority of start when SET command

is set after RST command. When X1 and

X2 act at the same time, Y1 is ON so it calls

top priority of start.

SET

Y1

RST

Y1

X2

X1

Top priority of start

The common control circuit

Example 4: condition control

X1 and X3 can start/stop Y1 separately, X2 and X4 can start/stop Y2 separately and they are all self

latched circuit. Y1 is an element for Y2 to do AND function due to the normally open contact

connects to Y2 in series. Therefore, Y1 is the input of Y2 and Y2 is also the input of Y1.

Call 1(800)985-6929 for Sales

deltaacdrives.com

sales@deltaacdrives.com

Call 1(800)985-6929 for Sales

deltaacdrives.com

sales@deltaacdrives.com