Chapter 15 Suggestions and Error Corrections for Standard AC Motor Drives

|

C200 Series

15-3

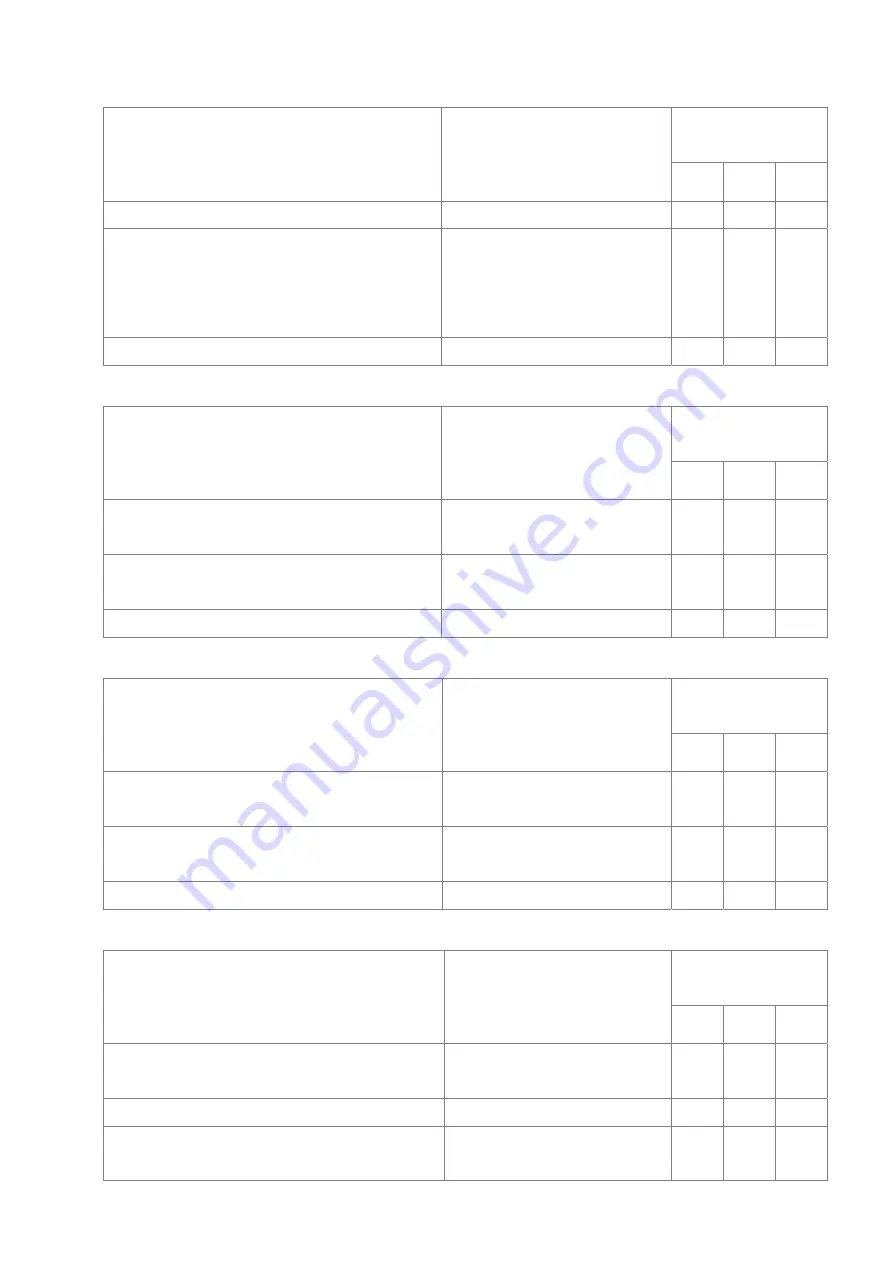

Main circuit

Maintenance

Period

Check Items

Methods and Criterion

Daily

Half

Year

One

Year

If there are any loose or missing screws

Tighten or replace the screw

○

If machine or insulator is deformed, cracked,

damaged or with color change due to

overheating or ageing

Visual inspection

NOTE: Please ignore the

color change of copper

plate

○

If there is any dust or dirt

Visual inspection

○

Terminals and wiring of main circuit

Maintenance

Period

Check Items

Methods and Criterion

Daily

Half

Year

One

Year

If the terminal or the plate is color change or

deformation due to overheat

Visual inspection

○

If the insulator of wiring is damaged or color

change

Visual inspection

○

If there is any damage

Visual inspection

○

DC capacity of main circuit

Maintenance

Period

Check Items

Methods and Criterion

Daily

Half

Year

One

Year

If there is any leak of liquid, color change,

crack or deformation

Visual inspection

○

If the safety valve is not removed? If valve is

inflated?

Visual inspection

○

Measure static capacity when required

○

Resistor of main circuit

Maintenance

Period

Check Items

Methods and Criterion

Daily

Half

Year

One

Year

If there is any peculiar smell or insulator

cracks due to overheat

Visual inspection, smell

○

If there is any disconnection

Visual inspection

○

If connection is damaged?

Measure with multimeter with

standard specification

○

Call 1(800)985-6929 for Sales

deltaacdrives.com

sales@deltaacdrives.com

Call 1(800)985-6929 for Sales

deltaacdrives.com

sales@deltaacdrives.com