Chapter 7 Optional Accessories

|

C200 Series

7-2

All Brake Resistors and Brake Units Used in AC Motor Drives

230V 1-phase

Applicable

Motor

*

1

125%Braking Torque 10%ED

*

2

Max. Brake Torque

HP kW

Braking

Torque

(kg-m)

*

3

Braking Resistor

series for each Brake

Unit

Resistor value

spec. for each

AC motor Drive

Total

Braking

Current

(A)

Min. Resistor

Value (

Ω

)

Max. Total

Braking

Current (A)

Peak Power

(kW)

0.5 0.4 0.27

BR080W200*1

80W200

Ω

1.9 63.3

6

2.3

1 0.75 0.51

BR080W200*1

80W200

Ω

1.9 63.3

6

2.3

2 1.5 1.0

BR200W091*1

200W91

Ω

4.2 47.5

8

3.0

3 2.2 1.5

BR300W070*1

300W70

Ω

5.4 38.0

10

3.8

230V 3-phase

Applicable

Motor

*

1

125%Braking Torque 10%ED

*

2

Max. Brake Torque

HP kW

Braking

Torque

(kg-m)

*

3

Braking Resistor

series for each Brake

Unit

Resistor value

spec. for each

AC motor Drive

Total

Braking

Current

(A)

Min. Resistor

Value (

Ω

)

Max. Total

Braking

Current (A)

Peak Power

(kW)

0.5 0.4 0.27

BR080W200*1

80W200

Ω

1.9 63.3

6

2.3

1 0.75 0.51

BR080W200*1

80W200

Ω

1.9 63.3

6

2.3

2 1.5 1.0

BR200W091*1

200W91

Ω

4.2 47.5

8

3.0

3 2.2 1.5

BR300W070*1

300W70

Ω

5.4 38.0

10

3.8

5 3.7 2.5

BR400W040*1

400W40

Ω

9.5 19.0

20

7.6

460V

Applicable

Motor

*

1

125%Braking Torque 10%ED

*

2

Max. Brake Torque

HP kW

Braking

Torque

(kg-m)

*

3

Braking Resistor

series for each Brake

Unit

Resistor value

spec. for each

AC motor Drive

Total

Braking

Current

(A)

Min. Resistor

Value (

Ω

)

Max. Total

Braking

Current (A)

Peak Power

(kW)

1 0.75 0.5

BR080W750*1

80W750

Ω

1 190.0 4

3.0

2 1.5 1.0

BR200W360*1

200W360

Ω

2.1 126.7

6

4.6

3 2.2 1.5

BR300W250*1

300W250

Ω

3 108.6 7

5.3

5 3.7 2.5

BR400W150*1

400W150

Ω

5.1 84.4

9

6.8

5.5 4.0

2.7

BR1K0W075*1

1000W75

Ω

10.2 54.3

14

10.6

7.5 5.5

3.7

BR1K0W075*1

1000W75

Ω

10.2 54.3

14

10.6

10 7.5

5.1

BR1K0W075*1

1000W75

Ω

10.2 47.5

16

12.2

*

1

Calculation for 125% brake toque: (kw)*125%*0.8; where 0.8 is motor efficiency.

Because there is a resistor limit of power consumption, the longest operation time for 10%ED is 10sec (on: 10sec/ off:

90sec).

*

2

Please refer to the Brake Performance Curve for “Operation Duration & ED” vs. “Braking Current”.

*

3

For heat dissipation, a resistor of 400W or lower should be fixed to the frame and maintain the surface temperature below

50

℃

; a resistor of 1000W and above should maintain the surface temperature below 350 .

℃

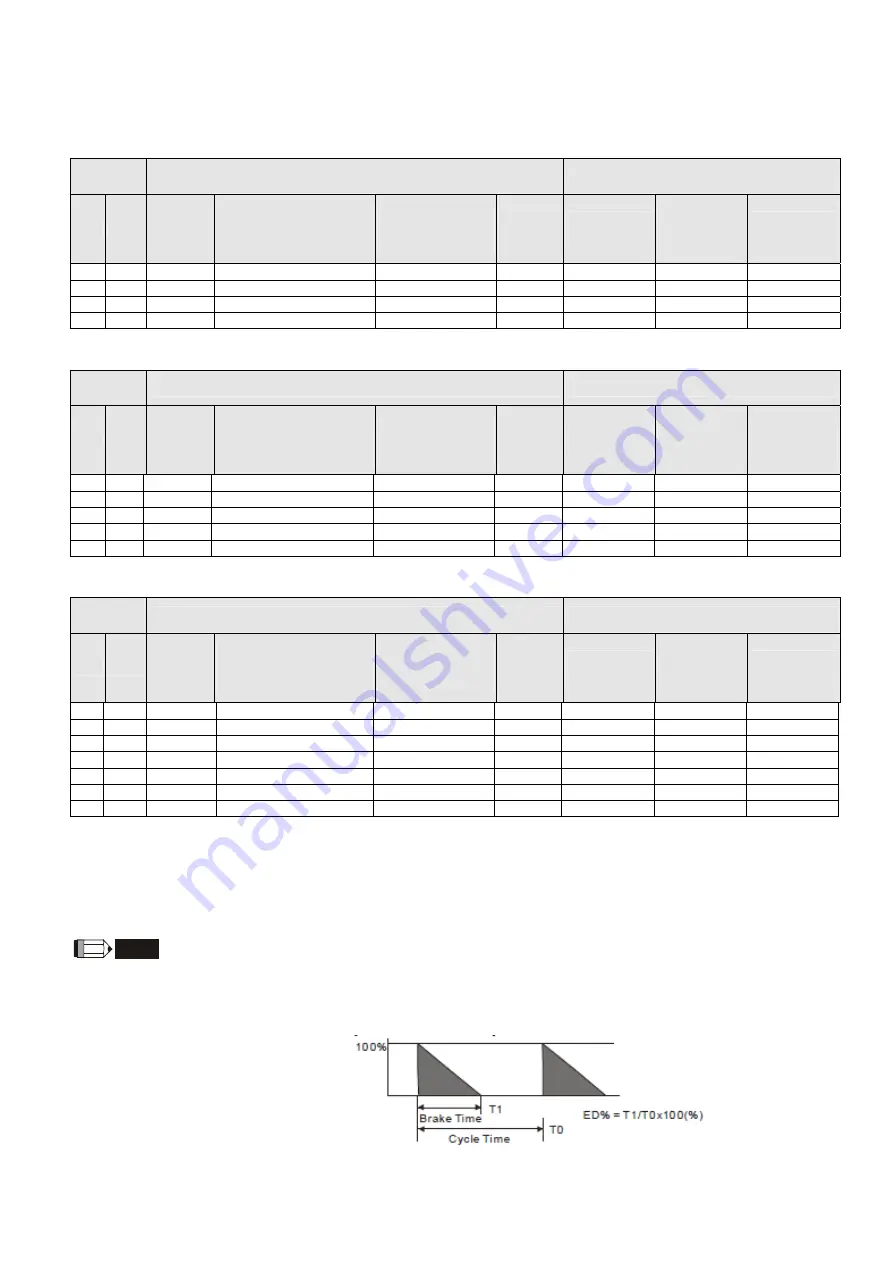

NOTE

1.

Definition for Brake Usage ED%

Explanation: The definition of the brake usage ED (%) is for assurance of enough time for the brake unit and brake resistor

to dissipate away heat generated by braking. When the brake resistor heats up, the resistance would increase with

temperature, and brake torque would decrease accordingly. Recommended cycle time is one minute.

Call 1(800)985-6929 for Sales

deltaacdrives.com

sales@deltaacdrives.com

Call 1(800)985-6929 for Sales

deltaacdrives.com

sales@deltaacdrives.com