Chapter 7 Optional Accessories

|

C200 Series

7-3

For safety concern, install an overload relay (O.L) between the brake unit and the brake resistor in conjunction with the

magnetic contactor (MC) prior to the drive for abnormal protection. The purpose of installing the thermal overload relay is to

protect the brake resistor from damage due to frequent brake, or due to brake unit keeping operating resulted from unusual

high input voltage. Under such circumstance, just turn off the power to prevent damaging the brake resistor.

2.

If damage to the drive or other equipment is due to the fact that the brake resistors and brake modules in use are not

provided by Delta, the warranty will be void.

3.

Take into consideration the safety of the environment when installing the brake resistors. If the minimum resistance value is

to be utilized, consult local dealers for the calculation of Watt figures.

4.

This chart is for normal usage; if the AC motor drive is applied for frequent braking, it is suggested to enlarge 2~3 times of

the Watts.

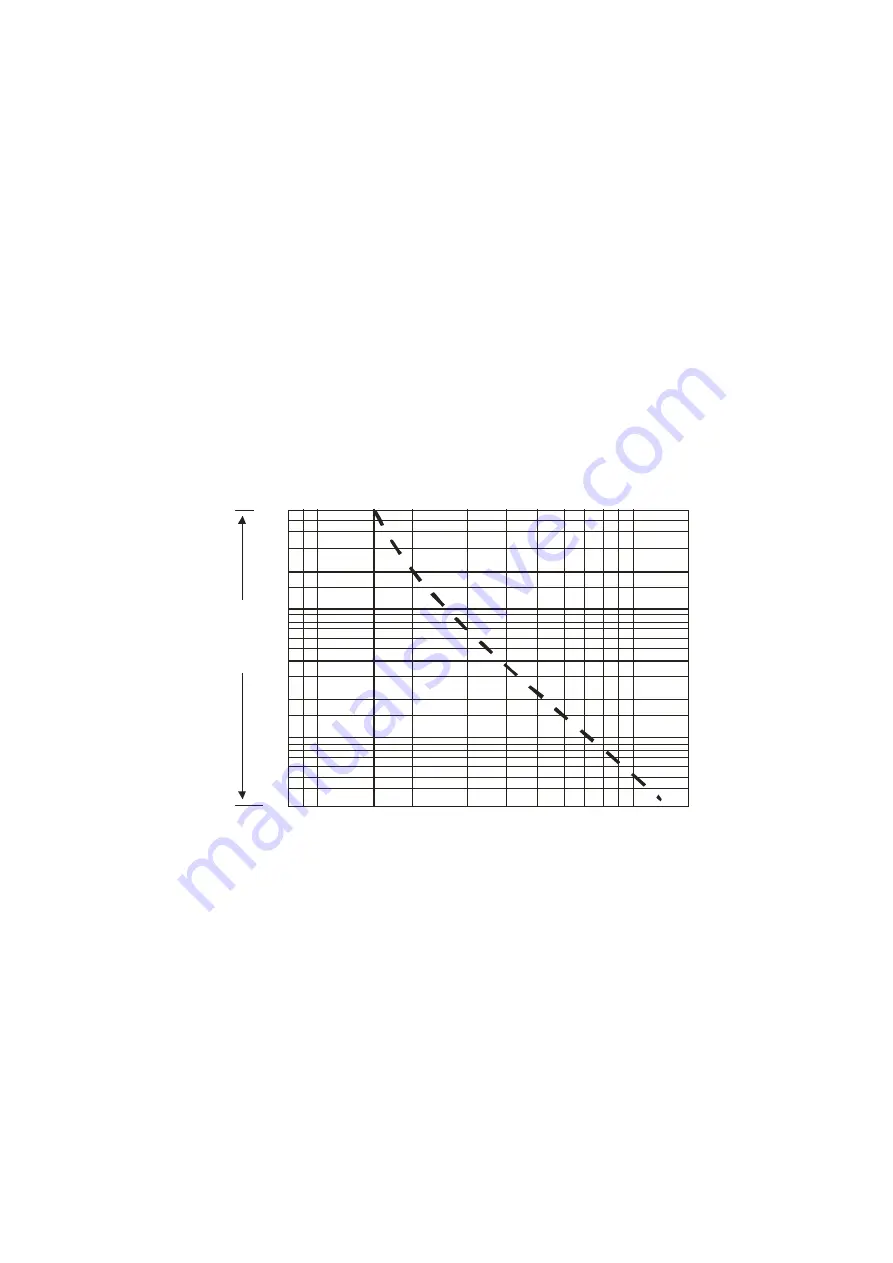

5. Thermal

Relay:

Thermal relay selection is basing on its overload capability. A standard braking capacity for C2000 is 10%ED (Tripping

time=10s). The figure below is an example of 406V, 110kw AC motor drive. It requires the thermal relay to take 260%

overload capacity in 10s (Host starting) and the braking current is 126A. In this case, user should select a rated 50A

thermal relay. The property of each thermal relay may vary among different manufacturer, please carefully read

specification.

60

40

30

20

10

T

ri

p

p

in

g ti

m

e

8

3

2

4

6

1

0.8

0.6

0.4

0.3

0.8 1

1.5

2

3

4

5

6

8

10

15

7

9

Multiple of current setting

xln (A)

S

ec

ond

Call 1(800)985-6929 for Sales

deltaacdrives.com

sales@deltaacdrives.com

Call 1(800)985-6929 for Sales

deltaacdrives.com

sales@deltaacdrives.com